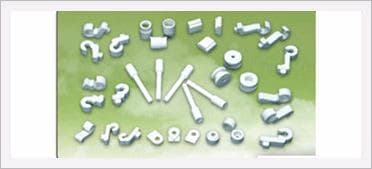

Steatite

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- hannam ceramic, mullite, sintered product, steatite

- Category

Hannam Ceramic Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Steatite | Certification | - |

|---|---|---|---|

| Category | Ingredients | - | |

| Keyword | hannam ceramic , mullite , sintered product , steatite | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Feature

Steatite is a dense porcelain, having Talc as main material and magnesium m-silicate as main crystalloid.

It is produced by the following steps : Mixing small amount of kaoline and organic substance bonding agent in Talc, extruding or high-pressure press shape forming, and sintering around 1250°C.

The Coefficient of Thermal Expansion is 7~8x1026K, and it is used for high-frequency electrical insulation materials.

|

Densityρ(20°C)

[kg/m3] |

Coefficient of thermal

expansion α (0°C-100°C) [10-5K-1] |

Specific heat C (20°C)

|

Thermal

conductivity (20°C) |

|

|

[kJ/kg.K]

|

[㎈/g.k]

|

|||

|

2.6∼2.8

|

0.7∼0.9

|

1.3

|

0.311

|

2.3

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Bong-chan Kim

- Address

- 605-2, Owol-ri, Buki-myeon, Jangseong-gun, Jeollanam-do, Korea

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Hannam Ceramic has contributed to the high-tech material industry with abundant technical human resources and experience as a manufacturer of fine ceramic for abrasion resistance, acid-resistance, thermal resistance and electronic-eletrical parts.

In this fast developing era of technological inovation, companies are required to achieve quality improvement, cost-saving, and easy management. To respond these trends, Hannam Ceramic exerts the best efforts for manufacturing superior products by standardizing all manufacturing processes as well as conducting in-hour5-policy campain and doing our best for quality management.

All employes of Hannam Ceramic take their energetic steps toward creation for tomorrow, based on a study pioneer spirit and a dream. Hannam Ceramic will do its best for giving reliability to customers. Thank you.

- Main Product