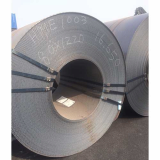

Alu-zinc Alloy Coated Steel Sheet Coil (GALVALUME)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- POSCO C&C, DONG-BU STEEL, UNION STEEL

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Steel Sheets

Sechang Steel Co,. Ltd.

- Verified Certificate

-

17

| Product name | Alu-zinc Alloy Coated Steel Sheet Coil (GALVALUME) | Certification | - |

|---|---|---|---|

| Category | Steel Sheets | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | POSCO C&C, DONG-BU STEEL, UNION STEEL | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | 721061 |

Product Information

ASTM A792 / A792M-097

Standard Specification for Steel Sheet, 55% Aluminum-Zinc Alloy-Coated by the Hot Dip Process>

Scope

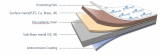

- This specification covers 55% aluminum-zinc alloy- coated steel sheet in coils and cut lengths.

- This product is intended for applications requiring corrosion resistance or heat resistance, or both.

- This product is produced in a number of designations, types, and grades which are designed to be compatible with differing application requirements.

Terminology

- Definitions-See Terminology A902 for definitions of general terminology relating to metallic-coated hot-dip products.

- Definition of Term Specific to This Standard.

- Regular spangle-the unaltered 55% aluminum-zinc(Al-Zn) crystal structure that occurs during normal solidification of a hot-dip coated steel sheet.

Classification

- The material is available in several designations, as follows;

- Commercial Steel-CS Type A, B, and C,

- Forming Steel-FS

- Drawing Steel-DS

- High Temperature Steel-HTS, and}

- Structural Steel-SS.

- Structural steel is available in several grades based on yield strengths and tensile strength.

- The product is available in several coating weights [masses]with the coating designation.

Coating Designation and Minimum Coating Test Limits

|

Coating Designation |

Triple-spot Test |

Sing-Spot Test min g/m2 min oz/ft2 |

|

AZM 150 AZ 50 |

150 0.50 |

130 0.43 |

|

AZM 165 AZ 55 |

165 0.55 |

150 0.50 |

|

AZM 180 AZ 60 |

180 0.60 |

155 0.52 |

EN 10215/1995

Continuously Hot-Dip Aluminum-(AZ)Coated Steel Sheet and Strip(Technical Delivery Conditions)

1. Grades and Mechanical Properties of Low Carbon steels for Cold Forming

|

Designation |

Yield Strength Re |

Tensile Strength |

Elongation |

||

|

Steel Grade |

Symbol for the |

||||

|

steel Name |

Steel Number |

||||

|

D X 51D |

1.0226 |

+AZ |

- |

500 |

22 |

|

D X 52D |

1.0350 |

+AZ |

3005) |

420 |

26 |

|

D X 53D |

1.0355 |

+AZ |

260 |

380 |

30 |

|

D X 54D |

1.0306 |

+AZ |

220 |

350 |

36 |

1) The values apply to transverse test pieces

2) The yield strength values apply to the 0.2% proof stress if the yield point is not pronounced, otherwise to the lower yield strength(ReL)

3) For all steel grades a minimum value of 140 N/mm2 for the yield strength (Re) and of 270 N/mm2 for the tensile strength (Rm) may be expected

4) For product thickness <0.7mm the minimum elongation values(A80)shall be reducedby 2 units

5) This value applies to skin passed products only(surface qualities B and C)

2.Grades and Mechanical Properties of Structural Steels

|

Designation

|

Yield Strength Re

N/mm2 max.1) 2) 3) |

Tensile Strength

Re N/mm2 max.1) 3) |

Elongation

A80 % min.1) 4) |

||

|

Steel Grade

|

Symbol for the

Type of Hot-Dip Coating |

||||

|

steel Name

|

Steel Number

|

||||

|

S250GD+AZ

|

1.0242

|

+AZ

|

250

|

330

|

19

|

|

S250GD+AZ

|

1.0244

|

+AZ

|

280

|

360

|

18

|

|

S250GD+AZ

|

1.0250

|

+AZ

|

320

|

390

|

17

|

|

S250GD+AZ

|

1.0529

|

+AZ

|

350

|

420

|

16

|

|

S250GD+AZ

|

1.0531

|

+AZ

|

550

|

560

|

|

1) The values apply to transverse test pieces

2) The yield strength values apply to the 0.2% proof stress if the yield point is not pronounced, otherwise to the upper yield strength(ReH)

3) For product thickness < 0.7mm the minimum elongation values(A80) shall be reduced by 2 units

3. Coating Mas

|

Coating Designation

|

Minimum Coating Mass, g/m2 Total Both Surfaces

|

|

|

Triple Spot Test

|

Single Spot Test

|

|

|

100

|

100

|

85

|

|

150

|

150

|

130

|

|

185

|

185

|

160

|

1) A coating mass of 100 g/m2 corresponds go a coating thickness of approximately 13.3µm on

Specific uses

- Industrial

- Roofing material Internal Wall Ceiling Fence

- Muffler Exhaust Silence Boxes Tail pipe Oil filter Tube Hose Clamp Brake Pad Cover

- Banding machine Washing machine Microwave ovens

170

SPECIFIC USES

Power distribution board , Air conditioning components, Shutter door, Roofing material, Internal wall

* Thickness : 0.40 mm ~ 2.30 mm

* Width : 800 mm ~ 2300 mm

* Min. Order Quantity : 20 ~25 MT / one 20ft container

* Packing : export standard steel packing (coil - horizontal, vertical / sheet - according to customer's order)

* Price : FOB Busan (negotiation with Mill's) + sea freight + commission + insurance premium

* Payment Term : T/T advance 20%, L/C at sight, L/C 90 days from B/L date

* Delivery Time : 45 ~ 60 days from L/C or Mill's option

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- PARK, SUNG-JOO

- Address

- 662 Gasul-ri, Daesan-myeon, Uichang-gu, Changwon-si, Gyeongsangnam-do, Korea

- Product Category

- Ladders & Scaffoldings,Steel Pipes,Steel Sheets

- No. of Total Employees

- 1-50

- Company introduction

-

1984 Dec. Foundation of Sechang Steel

Registered as a distributor of Union Steel (1984), Dongbu Steel(1985), POSCO C&C (1992)

1990 Dec. Foundation of Gwangju Office

1995 Jan. Conversion into a corporation

1999 Nov. Received Minister of Industry & Resources Award and Export Tower on National Trade Day, Acquired certification of ISO/KS A9002 (Gwangju Office)

2004 Nov. Received Minister of Commerce, Industry and Energy Award and Export Tower on National Trade Day

2005 Nov. Received Export Tower on National Trade Day, CEO received Prime Minister Award

2006 Dec. Designated as the front-runner in the strategic industry(machinery part) by Busan Metropolitan City

2007 Dec. Received Award of Excellence in Export from Busan Metropolitan city

2009 Jun. Foundation of Changwon plant & relocation of head office

- Main Markets

-

Cyprus

Cyprus

N.Zealand

N.Zealand

Qatar

Qatar

Turkey

Turkey

U.A.E.

U.A.E.

- Factory Information

-

SE CHANG STEEL

- Main Product

Related Products

STEEL PLATE ROUND BAR

clad steel(Ecoteel)

Electro-Galvanized Steel Sheet(EGI)

PRINTEX

STEEL PRODUCTS

South Korea

South Korea