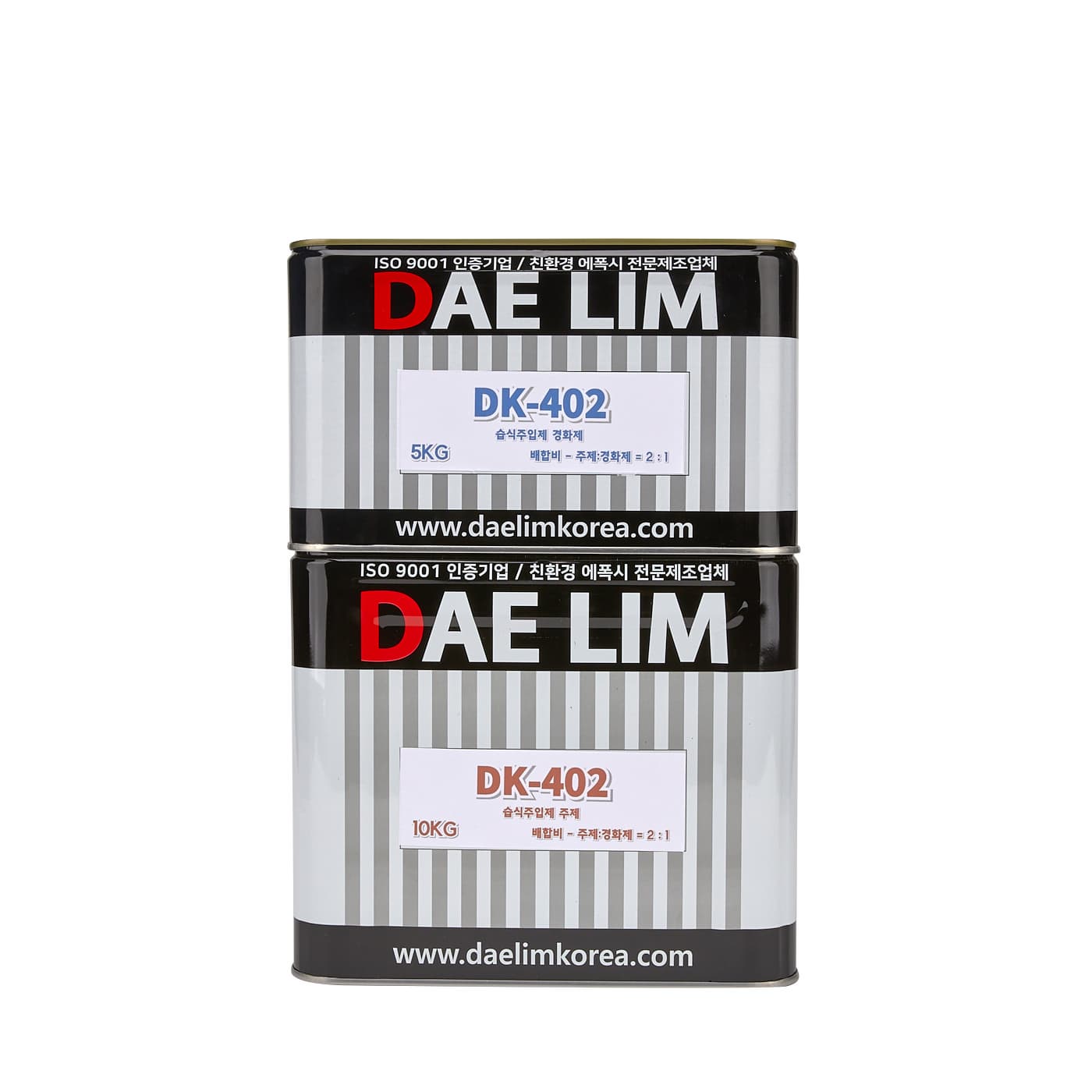

Wet Epoxy Crack Filler

Wet Epoxy Crack Filler for Building Restoration and Reinforcement

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Others,T/T

- Production method

- Available,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Wall Materials , Tiles & Accessories

Daelim Industry Co.,Ltd.

- Membership

- PRO

- Recent Visit

- Jan 08, 2025

- Country / Year Established

-

South Korea

/

2012

South Korea

/

2012

- Business type

- Others

- Verified Certificate

-

2

| Product name | Wet Epoxy Crack Filler | Certification | - |

|---|---|---|---|

| Category |

Wall Materials

Tiles & Accessories |

Material | - |

| Keyword | epoxy adhesive , tile adhesive , injection syringe , injection sealants | Unit Size | 231.0 * 231.0 * 205.0 mm |

| Brand name | - | Unit Weigh | 10 kg |

| origin | South Korea | Stock | 2000 |

| Supply type | Available,OEM | HS code | 390730 |

Product Information

- Fine Crack Penetration: With a low viscosity, it perfectly injects into micro-cracks.

- Fast Curing Properties: Easy to work with on wet surfaces, it exhibits minimal shrinkage after curing

- Strong Adhesion: Provides excellent bonding to wet concrete and cement.

- Durability: Resistant to chemical effects and excels in corrosion prevention.

- Mechanical Strength: Offers outstanding compressive, flexural, and tensile strength, making it suitable for repair and reinforcement tasks.

1.Investigation of Crack Areas and Selection of Construction Methods: The investigation of crack areas and the selection of construction methods involve a detailed analysis of the condition and characteristics of the cracks. This process allows for a precise assessment of their width, depth, and overall state, enabling the determination of suitable construction methods and the viscosity of injection materials.

There are two primary techniques for crack reinforcement. The first is a low-pressure injection method that uses the force of rubber bands or springs, while the second is a high-pressure injection method that employs injection machinery. The low-pressure method is typically used for repairing fine cracks or when cracks are externally visible, making identification and repair easier. It is also favored for reinforcing larger crack areas. Conversely, the high-pressure injection method utilizes machinery to inject materials into the cracks under high pressure. This technique effectively reinforces deep cracks or extensive areas, allowing materials to penetrate deeply. It is particularly useful when structural integrity is critical and in situations where quick repairs are needed.

2.Site Cleaning: Remove all contaminants such as grease, moss, and other debris from the crack area. Ensure that the area remains dry after cleaning to maximize the adhesion and effectiveness of the injection material.

3.Sealing and Stand Installation: Seal the crack with a sealing compound, then accurately position and attach the stand at the center of the crack. Proper alignment of the stand with the crack center is crucial.

4.Curing of Sealing Compound: Allow the sealing compound to cure fully. Ideally, the stand should remain in place without any movement when manually tested.

5.Injection Process: Measure and mix the injection material according to the specified ratio, then use a construction syringe to inject it. Ensure even distribution of the resin throughout the crack during the injection.

6.Curing of Injection Material: After the resin has completely cured, remove the injection cylinder. Check the curing state to ensure stability.

7.Finishing: Once the work is complete, remove the stand and clean up the sealing compound using a grinder. This final step enhances the overall quality of the repair.

▶ For more details, please request the Technical Data Sheet (TDS) or the specifications.

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T | Shipping time | Negotiable |

- President

- OH MIN

- Product Category

- Epoxy Adhesives

- Year Established

- 2012

- Main Markets

-

China

China

Italy

Italy

U.S.A

U.S.A

Viet Nam

Viet Nam

- Factory Information

-

Headquater

- Main Product

Related Products

600 Series - PVC Tile, LVT, Vinyl, Flooring

OA Tile

PVC TILE: Luminous Series

Sun Shade Net

LVT - Loose Lay, PVC Flooring, Vinyl Tile