Electric Taiyaki Machine, 5P, FPR-450S, Korea Taiyaki Maker

Bungeoppang machine, Taiyaki machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Sun Brand Machine, Made in Korea

- Payment Terms

- D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

JS Global Trading Co., Ltd.

- Membership

- VIP

- Recent Visit

- Jan 21, 2025

- Country / Year Established

-

South Korea

/

2017

South Korea

/

2017

- Business type

- Trading Company

- Verified Certificate

-

8

| Product name | Electric Taiyaki Machine, 5P, FPR-450S, Korea Taiyaki Maker | Certification | - |

|---|---|---|---|

| Category |

Food & Beverage Machinery

Food & Beverage Machinery Parts |

Material | - |

| Keyword | taiyaki machine , taiyaki maker , korea taiyaki machine , bungeoppang machine | Unit Size | - |

| Brand name | Sun Brand Machine, Made in Korea | Unit Weigh | 17 kg |

| origin | South Korea | Stock | 200 |

| Supply type | Available | HS code | 851660 |

Product Information

Korean Dessert!

Recently, “Fish Shaped Taiyaki Bread” is rapidly gaining popularity in the dessert business market.

It is a product manufactured by “Taeyang Industry”, the leading manufacturer of Taiyaki machine

(made in Korea). It can bake five fishes at a time. Less scratches due to triple treatment with 20-year-old Teflon coating technology.

■ Product Name: Electric Taiyaki Machine, 5P, FPR-450S

■ Machine size: 300 x 510mm (Some variations may occur in product size.)

■ Power consumption: 220V/1.5Kw or 110V/1.5Kw

■ Product weight: 16.5Kg

■ Taiyaki size: 13cm x 7cm x 1.4cm

■ Main Features

- The most popular product among electric big fish bread machines (Best Seller)

- No need to turn the dough over and it is easy to make taiyaki.

Ⅰ. Product installation preparation

1. Install the machine to keep it level and place the machine on a solid, dust-free place.

2. Power switch test

- Connect the power cord and conduct a power switch opening/closing test.

- Press the red button up to turn on the electricity and lower to turn off the electricity.

- If the power button is not turned on, request an A/S.

Ⅱ. How to operate

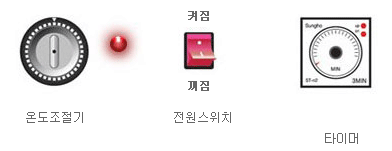

1. Raise the power switch up.

2. Set the temperature.

- Supply power to the heating unit and heat it to the desired temperature

(approximately 10 minutes up to 220℃).

- Turn the thermostat to the right and set to 180℃~200℃

3. Front Instrument Panel Description

- Power switch : Controls power.

- Thermostat : Temperature can be adjusted from 0℃ to 320℃

- Timer : Timer can be scheduled up to 10 minutes.

- Buzzer switch : Switch the buzzer on and off when the timer is activated.

1. Surface of Product

- Wipe foreign substances such as dust on the surface with a wet dishcloth.

- Remove moisture with a dry dishcloth.

- There is a risk of corrosion if water remains.

2. Mold

- After turning off the power, completely cool the mold and wipe it clean with a dry dishcloth.

- Do not use sharp or rough cloth as the coating may come off during cleaning.

3. Mold support

- Clean the grooves of the supports regularly as foreign substances may get stuck.

4. Front Controls Panel

- Turn off the power, unplug it, and use a wet dishcloth to remove any foreign substances.

- Remove residual moisture with a dry dishcloth after cleaning.

5. Beware of coating

- Be careful not to come into contact with sharp substances around the coating.

- Causes coating peeling.

Ⅳ. Storage method

1. If you do not use it for a long time, make sure to remove the plug from the outlet.

- It can cause electric shock due to heat insulation aging or fire due to short circuit.

2. After cleaning, wipe the assembled product with a soft cloth.

- Do not use sharp or rough cloth as the coating may come off when cleaning.

3. Cover it with plastic and store it so that dust, etc. do not accumulate.

4. Store it in a dry place.

- If stored for a long period of time, it may cause corrosion due to moisture, so do not store in the place that it may be wet.

5. Beware of coating

- Be careful not to come into contact with sharp substances around the coating.

- Causes coating peeling.

Ⅴ. Precautions Before Installation

1. Install this device in a horizontal position and at least 10cm away from the wall.

2. Be sure to use an applicable earth outlet (220v) for power supply.

- This product is for 220v only and when 110v electricity is used, the transformer

(rated capacity of 2.2 Kw or higher) is used. It must be purchased and installed separately.

3. Never use sharp tools on the coating side of the product.

- Please be informed that all services regarding coating are consumable and are paid.

4. The appropriate surrounding environment temperature of this product ranges from -5℃ to 35℃

5.Information on how to use and operate the product is not serviceable, so please refer to the user's manual.

Please contact the place of purchase.

6. If you need repair due to the failure, please refer it to the manufacturer's service center.

- The manufacturer is not responsible about any defects caused by non-special repairman other than our professional

service personnel. Thank you. End.

■ Product Name: Electric Taiyaki Machine, 5P, FPR-450S

■ Machine size: 300 x 510mm (Some variations may occur in product size.)

■ Power consumption: 220V/1.5Kw or 110V/1.5Kw

■ Product weight: 16.5Kg

■ Taiyaki size: 13cm x 7cm x 1.4cm

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Land Transportation,Negotiation Other,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- Kwon, Dong-Hyun

- Address

- Republic of Korea, Seoul, Guro-Gu, Digital-Ro, 26-Gil 123,#711, Guro-gu, Seoul, Korea

- Product Category

- Fruit & Vegetable Processing Machines

- Year Established

- 2017

- No. of Total Employees

- 1-50

- Company introduction

-

JS Global Trading Co., Ltd. is a successorof CK Company Limited. As a snow flake ice machine manufacturer and exporter, JS GlobalTrading Co., Ltd. has led the market share of Bingsu machine industry by365days 24 hours continuous R & D, the world best technology and endlesspassion since it’s foundation in 2012.

JS snow flake ice machine can manufacturethe delicious milk bingsu through rapid cooling type cooling drum system with the best technology.

<Company History>

2019.12.31 Exported our machines to total 49 countries.

2017.10.01 Manufacturing factory was changed from CK Company Ltd. to JS ENG Company Ltd.

2017.09.18 Established JS Global Trading Co., Ltd. for oversea sales

2015.10.21 Established Whaseong factory(2700pyeong)

2015.07.10 Recognized company affiliated research center

2015.06.05 Electric appliance safety certification by Korea Testing & Research Institute

2015.04.07 Electric appliance safety certification by Korea testing certification

2015.03.31 Signed contract with China, Vietnam and southeast Asia

2014.12.12 Patent(cooling function, hygiene control, assembly and durability)registration

2014.11.24 USA safety standard(ETL) certification approval

2014.10.23 Registered Incheon factory

2014.10.14 Relocation from Jongro-gu to Samsung-dong

2014.07.25 Signed oversea export contract with North America/South America

2013.06.27 Registration of sales and A/S of ice flake machine

2012.12.12 Established CK company

- Main Markets

-

Canada

Canada

Malaysia

Malaysia

U.S.A

U.S.A

- Factory Information

-

JS ENG HwaSung Factory

- Main Product

Related Products

Enterpack express food packaging machine

Popped rice cake machine, korea pop machine

Auto donuts machine(MR-9900)

BRESSO OVEN

Rice cake popping machine_K-Pop rice pop machine

_2.jpg)