AXIOMADE IV Catheter tube forming machine

An IV catheter tube forming machine shapes and molds catheter tubes into precise, functional forms for medical use.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- AXIOMADE

- Payment Terms

- D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- catheter, iv catheter, machine

- Category

- Other Machinery & Industry Equipment

DONGWOO M TECHNO

- Membership

- VIP

- Recent Visit

- Dec 02, 2024

- Country / Year Established

-

South Korea

/

1995

South Korea

/

1995

- Business type

- Manufacturer

- Verified Certificate

-

6

| Product name | AXIOMADE IV Catheter tube forming machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | catheter , iv catheter , machine | Unit Size | - |

| Brand name | AXIOMADE | Unit Weigh | - |

| origin | South Korea | Stock | 0 |

| Supply type | Available | HS code | - |

Product Information

An IV catheter tube forming machine is a specialized device used in the manufacturing of intravenous (IV) catheters. This machine is crucial for shaping and molding the catheter tubes into precise, functional forms, ensuring they meet medical standards for safe and effective use.

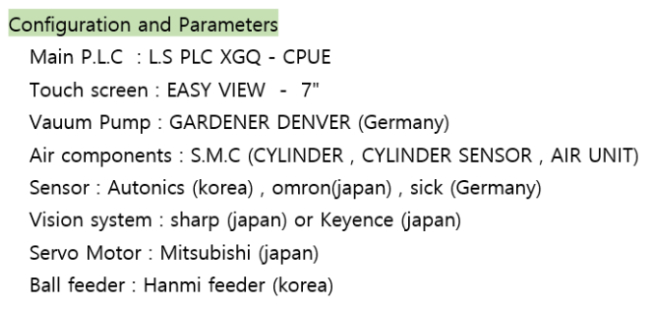

Components and Operation:

Feeding System: The process begins with the automatic feeding of raw catheter tubing material, which is typically made from polymeric materials like PVC or polyurethane. The machine pulls the tubing from spools or reels and prepares it for shaping.

Heating and Molding: The core of the tube forming machine involves heating the catheter tubing to a pliable state. This is achieved using controlled heating elements that uniformly heat the tubing material. Once heated, the tubing is fed into a mold or forming die, which shapes it into the required catheter form. The mold can be customized to create various catheter types and sizes, depending on the medical application.

Forming and Cooling: After the tubing is shaped by the mold, it is then cooled to solidify the formed shape. Cooling is typically done through air or water baths, depending on the material and design requirements. This step ensures that the catheter retains its intended form and dimensions once it solidifies.

Quality Control: The machine often includes integrated quality control systems to ensure that the formed catheters meet strict specifications. This may involve sensors and cameras that check for dimensional accuracy, surface defects, and overall quality of the finished product.

Output and Handling: Once formed and cooled, the catheters are typically cut to length if needed and collected for further processing or packaging. The machine may include conveyors or sorting systems to efficiently handle and direct the finished products.

Benefits:

- Precision: The machine ensures that IV catheters are formed to exact specifications, which is crucial for their functionality and safety.

- Efficiency: Automation speeds up the forming process, allowing for high-volume production and reducing manual labor.

- Consistency: The use of molds and controlled heating ensures uniformity in catheter dimensions and quality.

- Quality Assurance: Integrated quality control systems help maintain high standards and detect defects early.

In summary, an IV catheter tube forming machine is essential for producing high-quality, precisely shaped catheter tubes. Its automation, precision, and efficiency contribute significantly to the reliability and safety of IV catheters used in medical treatments.

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- JUNGPHIL LEE

- Address

- 209ho Technozone, 117 Hwanggeum-ro , Gimpo-si, Gyeonggi-do, KOREA

- Product Category

- Medical Devices

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

Dongwoo M Techno is a customer and quality oriented manufacturer of various needle products. Since its establishment it has exported its products to more than 50 countries and built its reputation as a reliable supplier of high quality products. With years of accumulated knowledge in quality management system and production technology, all products manufactured by Dongwoo M Techno as well as its facilities are GMP ISO quality certified

- Main Markets

-

Germany

Germany

Russia

Russia

U. Kingdom

U. Kingdom

- Main Product

,_Smartphone_dryer,_heating_mobile_2.jpg)