AXIOMADE Barrel printing machine

A barrel printing machine prints labels on syringe barrels, ensuring accurate and efficient marking for identification.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- AXIOMADE

- Payment Terms

- D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

DONGWOO M TECHNO

- Membership

- VIP

- Recent Visit

- Jan 14, 2025

- Country / Year Established

-

South Korea

/

1995

South Korea

/

1995

- Business type

- Manufacturer

- Verified Certificate

-

7

| Product name | AXIOMADE Barrel printing machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | barrel , machine , printing , syringe | Unit Size | - |

| Brand name | AXIOMADE | Unit Weigh | - |

| origin | South Korea | Stock | 0 |

| Supply type | Available | HS code | - |

Product Information

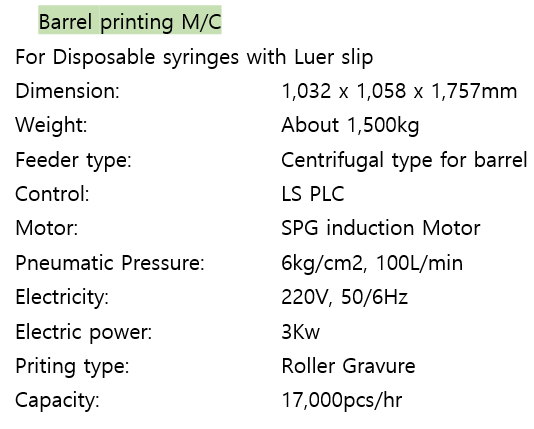

A barrel printing machine for syringe assembly is an essential device in the manufacturing process of syringes, designed to automate the application of labels or markings onto syringe barrels. This machine plays a crucial role in ensuring that syringes are accurately identified and traceable, which is vital for quality control, regulatory compliance, and patient safety.

The machine operates by feeding empty syringe barrels into the system, where they are positioned precisely for printing. It typically utilizes advanced printing technologies such as inkjet, pad printing, or laser marking. Each technology has its advantages; for example, inkjet printing is versatile and fast, pad printing offers high precision, and laser marking provides permanent, durable markings.

Once the barrels are correctly aligned, the machine applies the necessary information, which may include product names, batch numbers, expiration dates, and barcodes. This information is crucial for tracking the syringes throughout the supply chain and ensuring that they meet regulatory requirements. The printing process is highly automated, which minimizes human error and increases production efficiency.

The barrel printing machine is designed to handle high volumes with consistency and accuracy. It often includes features such as adjustable print settings, automated alignment mechanisms, and quality control sensors. These features help maintain the quality of the print and ensure that each syringe barrel meets the required standards. For instance, sensors may check for proper alignment and print quality, rejecting barrels that do not meet specifications.

By automating the printing process, the machine also significantly reduces labor costs and production time compared to manual methods. It ensures that syringes are marked accurately and efficiently, enhancing overall productivity and reliability in syringe manufacturing.

In summary, a barrel printing machine for syringe assembly is a vital tool in the production of syringes, providing accurate, efficient, and high-quality labeling essential for safety, compliance, and operational efficiency.

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- JUNGPHIL LEE

- Address

- 209ho Technozone, 117 Hwanggeum-ro , Gimpo-si, Gyeonggi-do, KOREA

- Product Category

- Medical Devices

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

Dongwoo M Techno is a customer and quality oriented manufacturer of various needle products. Since its establishment it has exported its products to more than 50 countries and built its reputation as a reliable supplier of high quality products. With years of accumulated knowledge in quality management system and production technology, all products manufactured by Dongwoo M Techno as well as its facilities are GMP ISO quality certified

- Main Markets

-

Germany

Germany

Russia

Russia

U. Kingdom

U. Kingdom

- Main Product

,_Smartphone_dryer,_heating_mobile_2.jpg)