This product comprises a sophisticated assembly of a cannula and a hub connected by a tube and catheter. It is engineered for the efficient absorption of liquid or semi-solid substances without the intention of re-injection. This feature is particularly important for applications where the primary goal is to withdraw or capture materials rather than to introduce them back into the body or system.

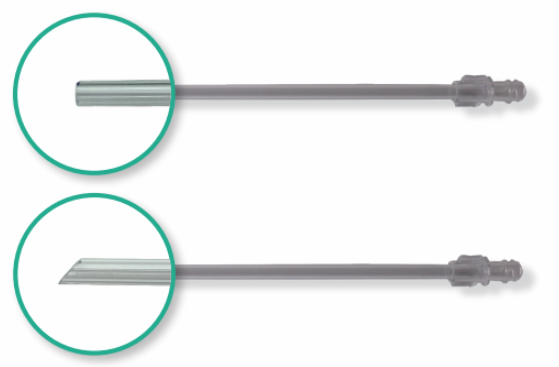

The cannula is designed with a variety of end shapes, which are categorized into O-type and D-type models. Each model is tailored to specific purposes, reflecting the versatility and adaptability of the product. The O-type model typically features a rounded end, ideal for applications that require a smooth, even intake of substances. This design minimizes the risk of damage to surrounding tissues or materials and ensures a more controlled absorption process. On the other hand, the D-type model is characterized by a different end shape, which may be optimized for more targeted or specific applications where a different absorption technique is necessary.

The integration of the tube and catheter with the cannula and hub ensures a seamless transfer of substances. The construction is designed to maximize efficiency and minimize any potential for leakage or contamination, contributing to the overall safety and hygiene of the procedure. This meticulous design consideration is essential for maintaining the integrity of the absorbed materials and for ensuring the product's reliability in various clinical or procedural contexts.

Moreover, the product's design emphasizes user comfort and procedural efficacy. The smooth surface of the cannula and catheter helps to reduce discomfort during use, while also promoting a more efficient absorption process. This aspect is crucial for enhancing patient outcomes and facilitating smoother procedural workflows.

In summary, this product offers a high level of functionality and precision, with its cannula and hub assembly designed for effective absorption of liquids and semi-solids. The availability of O-type and D-type models allows for tailored solutions based on specific application needs, while the focus on safety and user comfort underscores its utility in a range of procedural settings.

South Korea

South Korea

_2.png)