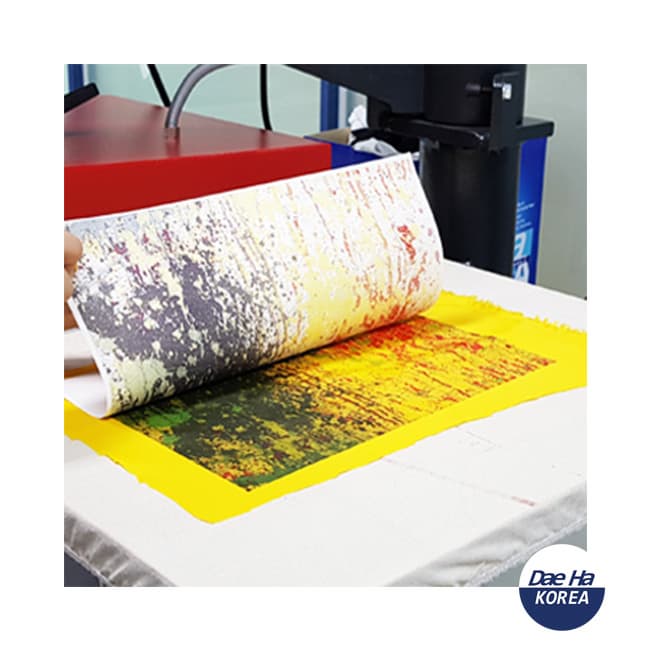

Sublimation Paper for Multi Purpose printing on Soft and Hard substances

It will work on Polyester based textiles, mugs, glasses, tiles and so on. It can print images very fast and precisely with clear and vivid color.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- DAE HA - SUBLIMATION PAPER

- Payment Terms

- T/T

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- mugs, sublimation paper, tiles, sublimation printing, multipurpose for textiles, soft and hard substrates, quick drying time after printing

- Category

- Transfer Film

DAE HA CO., LTD.

- Membership

- VIP

- Recent Visit

- Jan 21, 2025

- Country / Year Established

-

South Korea

/

2015

South Korea

/

2015

- Business type

- Manufacturer

Exhibition 1

FTA·AEO Expo- Verified Certificate

-

17

| Product name | Sublimation Paper for Multi Purpose printing on Soft and Hard substances | Certification | - |

|---|---|---|---|

| Category | Transfer Film | Ingredients | CELLULOSE |

| Keyword | mugs , sublimation paper , tiles , sublimation printing , multipurpose for textiles , soft and hard substrates , quick drying time after printing | Unit Size | - |

| Brand name | DAE HA - SUBLIMATION PAPER | Unit Weigh | 0 mg |

| origin | South Korea | Stock | 9999 |

| Supply type | Available | HS code | 480990 |

Product Information

■Multi Purpose [M TYPE]

Dae Ha Sublimation Paper M Type is designed to be an all-around sublimation paper for Soft and Hard substances. It will work on Polyester based textiles, mugs, glasses, tiles and so on.

All conventional sublimation paper has a chemical coating on the paper surface. But for M type, the sub chemicals have been penetrated into paper inside and enables designs to be easily and quickly absorbed inside the paper.

It can print images very fast and precisely, and can achieve perfect vivid color printing with no curling and no folding.

Dae Ha provides Sublimation Paper with consistent quality and enough capacity to meet constant demands.

Sublimation Paper Colors

- White unicolor with coating on paper

※ Note

- Dye sublimation transfer paper is mostly very weak against moisture.

- To protect unused papers, it is recommended to store the papers in its original packaging with inner poly bag at 59-86˚F / 15-30˚C and 30-50% RH.

- The possibility of curling is higher as the paper size gets smaller.

Features of M Type - Multipurpose for textiles, mugs, tiles, soft and hard substrates - Consistent Quality with capacity to meet constant demands - No extra coating on the surface of the paper - Absence of extra coating enables inks and designs to be quickly absorbed to the paper - Able to express vivid colors easier and quicker without cutting or weeding - No more loss of transferred materials - Quick dry after printing on sublimation paper - Anti-Curl and wrinkle free - No back gassing |

Specification

* MOQ: 1pallet (Quantities may vary depending on the size of the rolls or sheets)

* Other dimensions or special packing are available on request.

* It is essential to inform the core size when ordering.

Type

1. 49(50)gsm / 60gsm

- Designed to minimize the transfer time and temperature to improve productivity

- Minimum ink required for printing with fast drying time

- Translucent paper to see and adjust position of designs

- This specially processed 49gsm will be able to cover up to 59gsm

- Unsurpassed transfer yields with no back gassing

- Optimal for garments and textiles

2. 75gsm / 90gsm / 105gsm

- Sublimation paper with the most advanced technology

- Easy handling and superb transfer results

- Consistent and stable properties

- Fast drying time in high humidity & poor conditions.

- Able to express the most delicate and sharp lines

- Optimal for mugs, glasses, hard and soft substances.

3. 120gsm / 140gsm

- Designed to print and transfer very deep colors

- Stable at high speed printing with heavy ink loads

- Fast drying time and superb printing performance.

- Consistent performance from printing to thermal press.

- Optimal for mugs, glasses, hard and soft materials

Storage Conditions

- Dye sublimation transfer paper is mostly very weak against moisture.

- To protect unused papers, it is strongly recommended to store the papers in its original packaging with inner poly bag at 59-86˚F / 15-30˚C and 30-50% RH.

Tips

- Paper with higher G/m²(gsm) is easier to handle when printing but more amount of ink is required.

- Thermo tape and Teflon sheet are useful when holding the Sublimation Paper during heat press.

- Sublimation printing applicable on Dae Ha Design Film, Metallic Flex, Holographic Flex, Subli Fabric and Subli Flock.

Transfer Conditions of M Type

* Multipurpose such as mugs, banners, textiles, on various soft and hard materials

* Temperature and Time may vary depending on the pressed material

Suitable Printers (Piezo type)

- Dae Ha Sublimation paper has been tested successfully on the most famous brands of inkjet printing systems equipped with

dye sublimation inks. All Piezo Electric Drop on Demand printers like Epson, Mimaki, Mutoh, Roland and Kian printers have

shown excellent performance with our paper.

Washing Conditions

- Identical with washing conditions of the pressed material.

Note: - All information is given as guideline, the technical information and recommendations above are based on our test.

- We highly recommend that you perform a test prior to production.

- It is always recommended that the compatibility of the paper with a specific printer and heat press equipment be determined

before proceeding with the main and large printing job.

- Presented information in these pages is intended to offer a useful reference in selecting media for your output. Thus, no media

warranties are implied unless specifically mentioned. Printer, media and/or ink changes may give you some different printing

results. If the case of changing printer, media and/or inks, then, we recommend you to adjust your profile value.

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

DAE HA CO., LTD.

- Country / Year Established

-

South Korea

/

2015

South Korea

/

2015

- Membership

- VIP

- Recent Visit

- Jan 21, 2025

- Business type

- Manufacturer

Exhibition 1

FTA·AEO Expo-

17

- President

- KIM JIN WOON

- Address

- 9~10F DaeHa Bldg. 499 Gangseo-ro, Gangseo-gu, Seoul, Korea

- Product Category

- Garment Labels ,Other Fashion Manufacturing Materials,Transfer Film

- Year Established

- 2015

- No. of Total Employees

- 1-50

- Company introduction

-

Founded in 1986 manufacturing metallic films before expanding into the production of Heat Transfer Vinyl, DAE HA has acquired an excellent reputation as a sincere business partner serving both the Korean domestic and overseas markets.

The wealth of knowledge invested in our Research & Development of silicone releasing and colour coating, enables DAE HA to produce high quality Heat Transfer Flex products that we proudly export around the world.

The endeavours by our trusted employees for continual improvement have been rewarded by DAE HA obtaining both CE Mark and ISO accreditation. Whilst proud of our history, the Company Mission is to provide our customer base with the highest quality and service using the latest technology available.

At DAE HA, we believe we can ensure future prosperity and profits for our customers all over the world.

Thank you.

Donald Kim

Managing Director

Dae Ha Co., Ltd.

- Main Markets

-

Ecuador

Ecuador

Indonesia

Indonesia

South Africa

South Africa

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

- Attached File