The O2 generator is operated under the following mechanism: Oxygen is supplied by separating nitrogen from compressed air, using desiccants filled in two absorbers. Compressed air including both nitrogen and oxygen supplies oxygen by adsorbing nitrogen while passing through a zeolite molecular sieve (ZMS) layer which has micro pores filled in the absorbers.

The two absorbers repeat pressurizing, absorbing, depressurizing and washing by taking turns and supply oxygen consecutively.

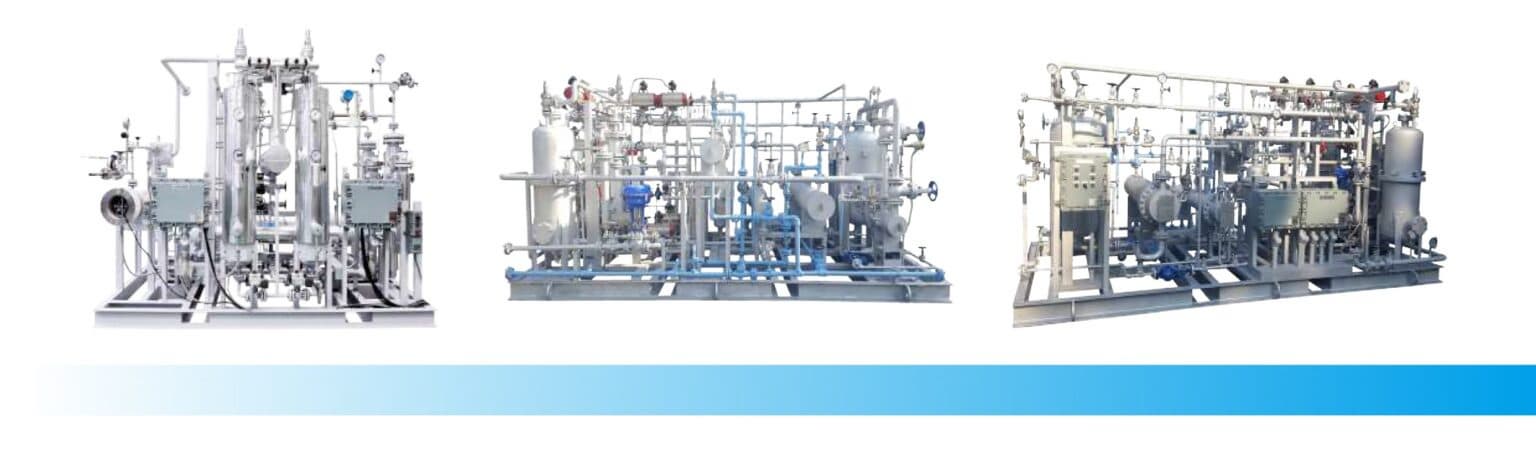

GSA’s pressure swing adsorption (PSA)-based O2 generator has a specially designed distributor at the bottom of the absorber so that it is able to supply high-quality oxygen which meets customer needs in a continuous and stable manner. In addition, the use of durable valves enables stable operation. Since diverse features needed to control the system are supported, settings and operations which meet user needs are enabled.

South Korea

South Korea