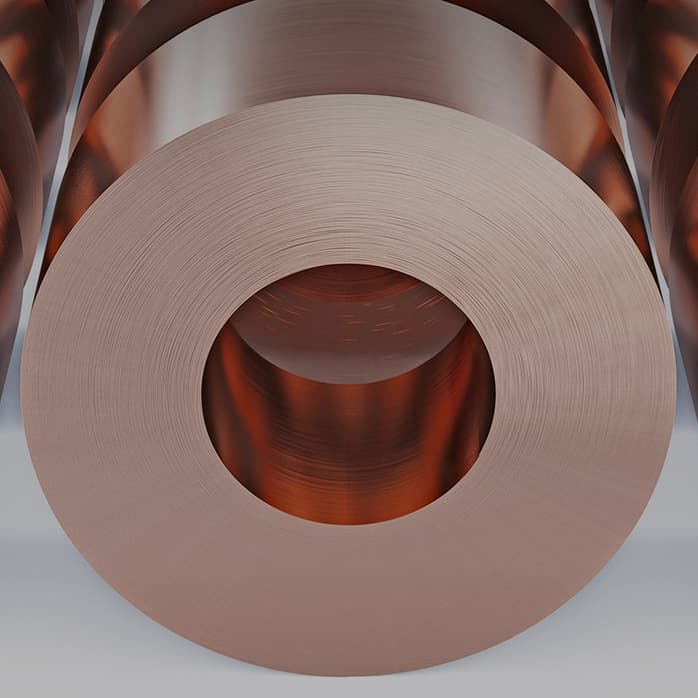

PHOSPHOR BRONZE STRIP

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- copper alloy, phosphor bronze

- Category

- Copper Bars & Strips

LEEKU INDUSTRIAL CO., LTD.

- Membership

- VIP

- Recent Visit

- Nov 13, 2024

- Country / Year Established

-

South Korea

/

1968

South Korea

/

1968

- Business type

- Manufacturer

- Verified Certificate

-

16

| Product name | PHOSPHOR BRONZE STRIP | Certification | - |

|---|---|---|---|

| Category | Copper Bars & Strips | Ingredients | - |

| Keyword | copper alloy , phosphor bronze | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Phosphor Bronze 1

- Alloy No C5102

- Characteristics non-corrosion

- Applications electronic appliances, relays

- Other information P was added to deoxidize the alloy of copper and zinc. Phosphor has high impact strength and strong ductility. So it can be widely used for good quality springs and electronic devices where high conductivity is required.

Phosphor Bronze 2

- Alloy No C5191

- Characteristics Chemical durability, good strength

- Applications Terminal, connector, electronic appliances, communication devices

- Other information P was added to deoxidize the alloy of copper and zinc. Phosphor has high impact strength and strong ductility. So it can be widely used for good quality springs and electronic devices where high conductivity is required.

Phosphor Bronze 3 Phosphor bronze for spring

- Alloy No C5210

- Characteristics Excellent chemical durability and strength, springiness, abrasion resistance

- Applications Terminals, connectors, communication devices, springs

- Other information P was added to deoxidize the alloy of copper and zinc. Phosphor has high impact strength and strong ductility. So it can be widely used for good quality springs and electronic devices where high conductivity is required.

| ALLOY NAME | DETONATOR | PHOSPHOR BRONZE | CONNECTOR / LEAD FRAME | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C2051 | C5102 | C5191 | C5210 | Sn_Cu (C1441) | LFC (C1921) | C194 (C1940) | C4250 | LK7020 | ||

| CHEMICAL COMPOSITION (wt%) | Cu:98.0-99.0 Zn:Remainder Pb:≤0.05 Fe:≤0.05 | Cu+Sn+P:≥99.5 Sn:4.5-5.5 P:0.03-0.35 Zn:≤0.20 Pb:≤0.02 Fe:≤0.1 | Cu+Sn+P:≥99.5 Sn:5.5-7.0 P:0.03-0.35 Zn:≤0.20 Pb:≤0.02 Fe:≤0.1 | Cu+Sn+P:≥99.7 Sn:7.0-9.0 P:0.03-0.35 Zn:≤0.20 Pb:≤0.02 Fe:≤0.1 | Sn:0.1-0.15 Fe:≤0.02 P:≤0.015 Cu:Remainder (Cu+Ag+Sn:≥99.96) | Fe:0.05-0.15 P:0.025-0.04 Cu:Remainder | Fe:2.1-2.6 P:0.015-0.15 Zn:0.05-0.2 Pb:≤0.03 Cu:Remainder | Cu:87.0-90.0 Sn:1.5-2.5 Pb:≤0.05 Fe:≤0.05 P:≤0.35 Zn:Remainder | Ni:1.2-2.0 Si:0.3-0.4 Mg:≤0.15 Cu:Remainder | |

| Specific Gravity (gm/cm³) | 8.88 | 8.9 | 8.8 | 8.8 | 8.93 | 8.94 | 8.8 | 8.78 | 8.85 | |

| Thermal Expansion Coefficient (10-6/℃ @20~300℃) | (no data) | 17.8 | 18 | 18.2 | 17.3 | 16.9 | 17.9 | 18.4 | 17.2 | |

| Thermal Conductivity (W/m·K @20℃) | (no data) | 71 | 67 | 63 | 330 | 364 | 262 | 121 | 208 | |

| Electrical Conductivity (%IACS @20℃) | (80) | ≥ 13 (15) | ≥ 12 (13) | ≥ 11 (12) | ≥ 80 (85) | ≥ 85 (90) | ≥ 60 (72) | ≥ 25 (28) | ≥ 55 (60) | |

| Tensile Strength (N/㎟) | O | Only for "O" | ≥ 305 | ≥ 315 | - | ≥ 195 | 255 - 345 | 275 - 415 | ≥ 295 | - |

| 1/4H | 215 - 255 | 375 - 470 | 390 - 510 | - | 215 - 305 | 275 - 375 | - | 335 - 420 | - | |

| 1/2H | For | 470 - 570 | 490 - 610 | 470 - 610 | 245 - 345 | 295 - 430 | 365 - 435 | 390 - 480 | 490 - 620 | |

| 3/4H | Thickness | - | - | - | - | - | - | 420 - 510 | - | |

| H | 0.2 - 0.35 | 570 - 665 | 590 - 685 | 590 - 705 | 275 - 400 | 335 - 470 | 415 - 485 | 480 - 570 | 590 - 660 | |

| EH | 215 - 255 | 620 - 710 | 635 - 720 | 685 - 785 | 345 - 440 | - | 460 - 505 | ≥ 520 | - | |

| SH | For | ≥ 660 | ≥ 690 | 735 - 835 | ≥ 380 | - | 480 - 525 | - | - | |

| ESH | Thickness | - | - | 770 - 885 | - | - | 505 - 590 | - | - | |

| SSH | 0.35 - 0.6 | - | - | - | - | - | ≥ 550 | - | - | |

| Elongation (%) | O | Only for "O" | ≥ 40 | ≥ 42 | - | ≥ 30 | ≥ 30 | ≥ 15 | ≥ 35 | - |

| 1/4H | ≥ 38 | ≥ 28 | ≥ 35 | - | ≥ 20 | ≥ 15 | - | ≥ 25 | - | |

| 1/2H | For | ≥ 15 | ≥ 20 | ≥ 27 | ≥ 10 | ≥ 6 | ≥ 5 | ≥ 15 | ≥ 10 | |

| 3/4H | Thickness | - | - | - | - | - | - | ≥ 5 | - | |

| H | 0.2 - 0.35 | ≥ 7 | ≥ 8 | ≥ 20 | ≥ 2 | ≥ 2 | ≥ 2 | - | ≥ 8 | |

| EH | ≥ 43 | ≥ 4 | ≥ 5 | ≥ 11 | - | - | - | - | - | |

| SH | For | - | - | ≥ 9 | - | - | - | - | - | |

| ESH | Thickness | - | - | ≥ 5 | - | - | - | - | - | |

| SSH | 0.35 - 0.6 | - | - | - | - | - | - | - | - | |

| Vicker's Hardness (Hv) | O | - | - | - | - | - | ≤ 100 | 70 - 125 | - | - |

| 1/4H | - | 90 - 160 | 100 - 160 | - | 45 - 105 | 90 - 120 | - | 80 - 140 | - | |

| 1/2H | - | 130 - 190 | 150 - 205 | 140 - 205 | 60 - 120 | 100 - 130 | 115 - 137 | 110 - 170 | 160 - 185 | |

| 3/4H | - | - | - | - | - | - | - | 140 - 180 | - | |

| H | - | 170 - 2150 | 180 - 230 | 185 - 235 | 90 - 125 | 110 - 150 | 125 - 145 | 140 - 200 | 175 - 200 | |

| EH | - | 190 - 230 | 200 - 240 | 210 - 260 | 100 - 135 | - | 135 - 150 | ≥ 150 | - | |

| SH | - | ≥ 200 | ≥ 210 | 230 - 270 | ≥ 115 | - | 140 - 155 | - | - | |

| ESH | - | - | - | 245 - 285 | - | - | 145 - 170 | - | - | |

| SSH | - | - | - | - | - | - | ≥ 140 | - | - | |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

LEEKU INDUSTRIAL CO., LTD.

- Country / Year Established

-

South Korea

/

1968

South Korea

/

1968

- Membership

- VIP

- Recent Visit

- Nov 13, 2024

- Business type

- Manufacturer

-

16

- President

- AHN,WEOL HWAN

- Address

- Poseung-eup, Poseunggongdan-ro,42, Pyeongtaek-si, Gyeonggi-do, Korea

- Product Category

- Copper Bars & Strips

- Year Established

- 1968

- No. of Total Employees

- 101-500

- Company introduction

-

Thank you very much for visiting our website.

Copper is one of the oldest and friendliest metals Humankind has known.

Since our foundation of the nation’s first rolling mill company taking part in the non-ferrous metal industry which was an unexplored field in 1968, we have grown up as a creditable company manufacturing and provides the best quality products at the right time at the right price.

With our customers’ hearty support, we will continue our efforts to develop new materials. The reasons why we have grown this much is not only from our customers, but also our employees working with the philosophy, harmony, commitment and creativity. Our new Poseung factory will upgrade all of our products, services and image.

We firmly promise to devote ourselves to be other global-oriented and future-oriented as a pioneer in non-ferrous material industry in the 21st century.

We hope you enjoy surfing our website. Thanks.

- Main Markets

-

China

China

Hong Kong(China)

Hong Kong(China)

Japan

Japan

Malaysia

Malaysia

Philippines

Philippines

South Korea

South Korea

Taiwan

Taiwan

Thailand

Thailand

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

Related Products

Brass Copper Strip

Brass Honey Scrap For Sale

Copper Bus Bars and Rods

Rolled Copper Foil

Nickel Silver Coil Plate