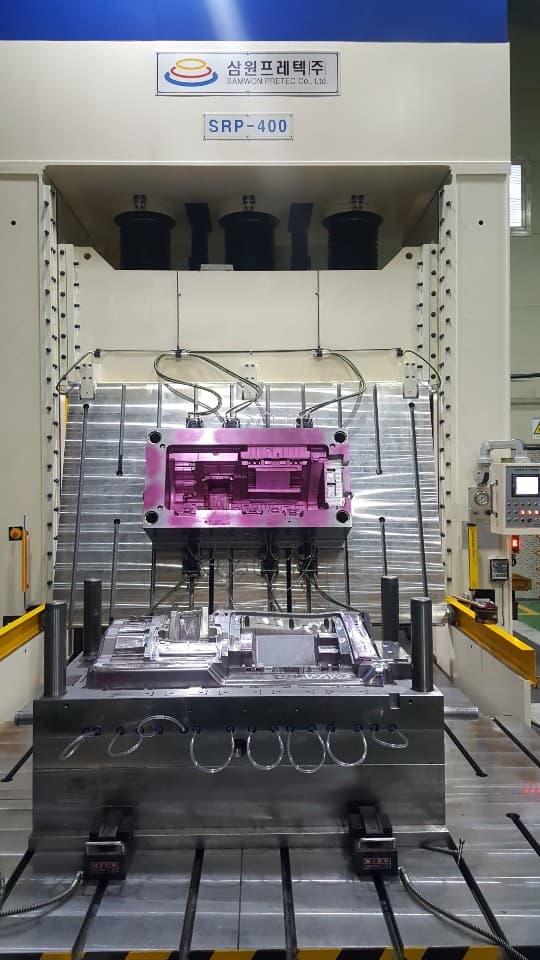

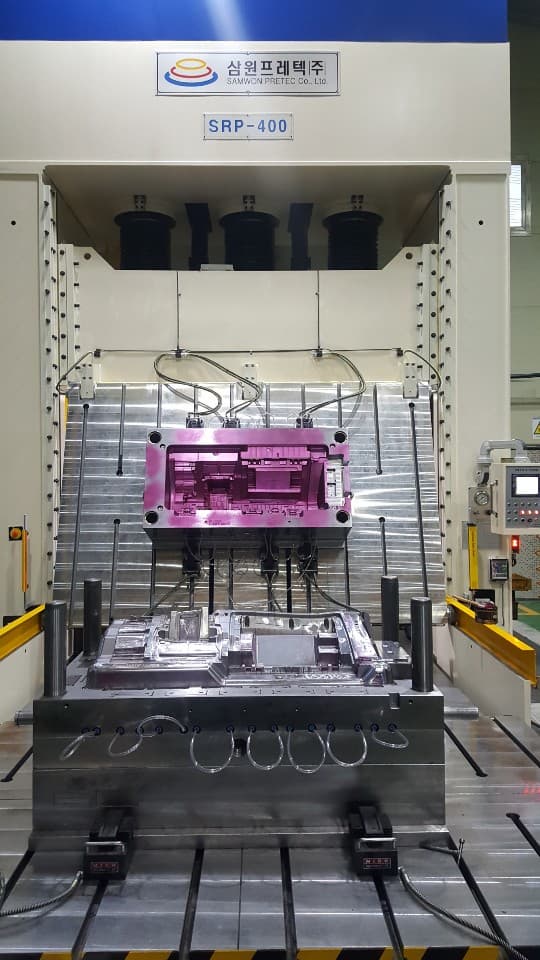

Hydraulic die spotting press machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- PRETEC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- hydraulic die spotting press machine, hydraulic trial press machine, hydraulic interior forming press machine, hydraulic metal formig press machine

- Category

- Metal Bending Machinery

SAMWON PRETEC CO LTD

- Verified Certificate

-

4

| Product name | Hydraulic die spotting press machine | Certification | Kosher |

|---|---|---|---|

| Category | Metal Bending Machinery | Ingredients | - |

| Keyword | hydraulic die spotting press machine , hydraulic trial press machine , hydraulic interior forming press machine , hydraulic metal formig press machine | Unit Size | 4000.0 * 6000.0 * 5000.0 mm |

| Brand name | PRETEC | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8462991040 |

Product Information

# Machinery propertys and strength

High standard of confguration ensures the excellent performance of machine, and all the main

components for mechanical processing are manufactured by imported machining center, to ensure machining precision of press elements. theshift-out rail of lower mold plate adopts wear resistant rail with intensifed handle and large-scale dust-proof device, Hydraulic system adopts

optimal combination of imported high performance hydraulic elements, and oil pump hydraulic valve is the world frst-class brand,also, the control part adopts the world's top-level brand PLC control system with big color LCD Screen, which provide convenient operaing.

Using high tensile rod to provide higher accuracy and to make more convenient for platen parallelism adjustment when the mold is closed with high pressure; Achieving digital PLC controlled by computer, all of the parameters can be displayed by the LS touch screen LCD and free to set up;

Using Multiple mold closing cylinder to make stress even when the mold is closed with high pressure;

Using quick cylinder device, it speede up null stroke without mold closing, and it makes lower energy consumption and more energy consevation. Using Anti-dropping, sagety devices with suspension type to make your mold and machine safer;

USABLE PURPOSE : FOR COMBINED PRODUCTION OF INJECTION MOLD SUB-CONTRACTING

# Machinery propertys and strength

High standard of confguration ensures the excellent performance of machine, and all the main

components for mechanical processing are manufactured by imported machining center, to ensure machining precision of press elements. theshift-out rail of lower mold plate adopts wear resistant rail with intensifed handle and large-scale dust-proof device, Hydraulic system adopts

optimal combination of imported high performance hydraulic elements, and oil pump hydraulic valve is the world frst-class brand,also, the control part adopts the world's top-level brand PLC control system with big color LCD Screen, which provide convenient operaing.

Using high tensile rod to provide higher accuracy and to make more convenient for platen parallelism adjustment when the mold is closed with high pressure; Achieving digital PLC controlled by computer, all of the parameters can be displayed by the LS touch screen LCD and free to set up;

Using Multiple mold closing cylinder to make stress even when the mold is closed with high pressure;

Using quick cylinder device, it speede up null stroke without mold closing, and it makes lower energy consumption and more energy consevation. Using Anti-dropping, sagety devices with suspension type to make your mold and machine safer;

USABLE PURPOSE : FOR COMBINED PRODUCTION OF INJECTION MOLD SUB-CONTRACTING

# Machinery propertys and strength

High standard of confguration ensures the excellent performance of machine, and all the main

components for mechanical processing are manufactured by imported machining center, to ensure machining precision of press elements. theshift-out rail of lower mold plate adopts wear resistant rail with intensifed handle and large-scale dust-proof device, Hydraulic system adopts

optimal combination of imported high performance hydraulic elements, and oil pump hydraulic valve is the world frst-class brand,also, the control part adopts the world's top-level brand PLC control system with big color LCD Screen, which provide convenient operaing.

Using high tensile rod to provide higher accuracy and to make more convenient for platen parallelism adjustment when the mold is closed with high pressure; Achieving digital PLC controlled by computer, all of the parameters can be displayed by the LS touch screen LCD and free to set up;

Using Multiple mold closing cylinder to make stress even when the mold is closed with high pressure;

Using quick cylinder device, it speede up null stroke without mold closing, and it makes lower energy consumption and more energy consevation. Using Anti-dropping, sagety devices with suspension type to make your mold and machine safer;

USABLE PURPOSE : FOR COMBINED PRODUCTION OF INJECTION MOLD SUB-CONTRACTING

- Verified Certificate

-

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

SAMWON PRETEC CO LTD

-

4

- President

- KIM EUN HWAN

- Address

- 19 Bodeum 8-ro Seo-gu Incheon, Seo-gu, Incheon, Korea

- Product Category

- Metal Bending Machinery,Metal Forging Machinery,Other Metal & Metallurgy Machinery

- Year Established

- 2017

- No. of Total Employees

- 1-50

- Company introduction

-

SAMWON PRETEC Machinery to provide customers with high quality and efficient pre-sale and

after-sales service to meet the needs of customers to continuously improve and enhance the

product quality and quality of service to improve customer satisfactioon.

- Main Markets

-

India

India

Indonesia

Indonesia

Viet Nam

Viet Nam

- Main Product

Related Products

Portable Rebar Cutter

Keel steel bending machine-cold frame bender

aluminium windows profiles

Φ168 Cold Forming Elbow Machine

Rebar Bender / Rebar Bending Machine

South Korea

South Korea