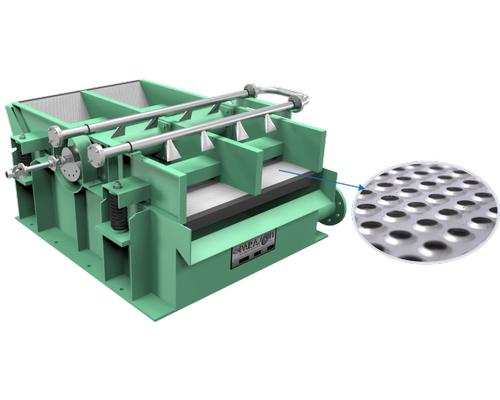

Slotted Vibrating Screen - Pulp And Paper Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- Parason

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- slotted vibrating screen

- Category

- Paper Processing Machines Parts

PARASON MACHINERY (INDIA) PRIVATE LIMITED

- Verified Certificate

-

7

| Product name | Slotted Vibrating Screen - Pulp And Paper Machine | Certification | - |

|---|---|---|---|

| Category | Paper Processing Machines Parts | Ingredients | - |

| Keyword | slotted vibrating screen | Unit Size | - |

| Brand name | Parason | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

Useful for handling reject of the slotted primary screen.

Vibrating Screen is designed for screening in lines for processing of chemical pulp, groundwood and waste paper where it is used mainly as an end part for final sorting of the reject from screening stages.

An advantage of this screen is its open design; the stock can be seen while being screened. Another advantage is that the screen eliminates possible clogging as it happens with the closed systems. Sorting screen is provided with bores or slots. Their dimensions depend on actual technological sorting requirements.

The vibrating screen can be anchored directly to a concrete floor or bolted to a steel frame. The vibrating screen itself consists of a tub that stands on anchor plates with springs. Those absorb the beats on the floor. The screen with a vibrator is located on four springs hitched to the tub. The vibrator is driven by an electric motor using a V-belt. There is a shower pipe hitched to the tub as well. When operating, the vibrator sets the screen in a vibrating motion. The motion is enabled by a shaft with eccentrics. The stock flows on a screen and, using the vibrating motion, the good stock goes through the screen into the tub, and the rest that can’t pass through the screen is moved upwards into a reject trough.

The screen reject is washed by the shower pipe on the screening part. The water level under the screen is adjustable with a slide so that the screen self-cleaning process would start. The impurities outlet, the good stock outlet from the screen and its inlet on the screening part must be solved for each project separately depending on the screen location. These parts do not form a part of the screen. For safety reasons, the machine is equipped with a belt cover and eccentric cover

Advantages:

- Possible utilization for the screening of diverse sorts of rejects

- Open design (visual inspection of the screening process)

- Easy maintenance and servicing

- Easy operation and high work safely

Material:

- The tub, screening part, and shower Pipe are made of Stainless Steel

- The vibrator, drive stand and Covers are made of structural steel and painted by a polyurethane Double-component Waterproof paint

Accessories:

It is possible to deliver a small inlet reservoir with a gate valve

Machine design and work safety are in compliance with EU standards

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Shekhar Desarda

- Address

- 28 Parason House, Anukrupa, No.28, Venkatesh Nagar, Aurangabad 431001 INDIA

- Product Category

- Paper Processing Machines Parts,Paper Product Machines

- Year Established

- 1977

- No. of Total Employees

- 501-1000

- Company introduction

-

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977.

Parason is focused on Research & Development. Many researches done by Parason shown that latest technology proposed by Parason not only enables Paper Mills to increase its Paper quality but also reduces huge power consumptions of machines which is the key point of Profit for Paper Industry. Parason offered products are widely used by Kraft, Tissue, Writing Printing and Hard Board Paper Mills. Parason also have specialization in Refiner Discs and these are one of best disc available for Paper mills across the globe. Parason manufactures various products which can be used for number of operations in stock preparation.

Parason have global consultancy services, which supports organization to setup New Paper Mills and also helps existing Paper Mills to archive higher goals. Parason also have international consultants based in Germany, Europe and USA.

Parason have worldwide client base and having majority market in Germany, USA, France, Thailand, Italy, Brazil, Spain, Portugal, Philippines, Indonesia, and Bangladesh, Parason serving more than 60 countries across world. Parason has successfully completed many installations for Paper Mills ranging from 25TPD to 400TPD.

- Main Product

India

India