Paper Manufacturing Machine For Paper Mills

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- Parason

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- paper manufacturing machine

- Category

- Paper Product Machines

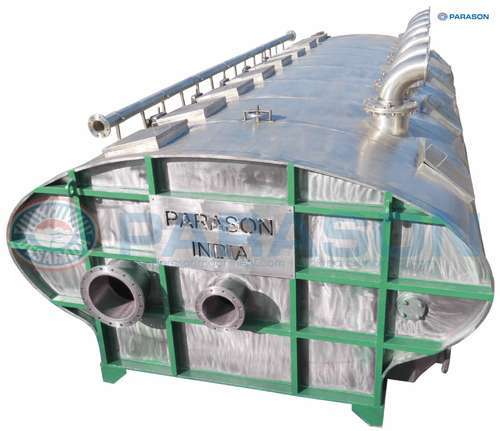

PARASON MACHINERY (INDIA) PRIVATE LIMITED

- Verified Certificate

-

7

| Product name | Paper Manufacturing Machine For Paper Mills | Certification | - |

|---|---|---|---|

| Category | Paper Product Machines | Ingredients | - |

| Keyword | paper manufacturing machine | Unit Size | - |

| Brand name | Parason | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

1. Accujethigh Turbulance Head Box

Advantages:

- Efficient control of cross-machine basis weight distribution

- Minimize grade change interval time

- Improves TSI values and TSO profiles over conventional tabulator roll headbox

- Improve the fiber orientation characteristic of the sheet.

- Through pulsation damping.

Parason Headbox System Features

- Better energy saving CDT/octopus

- Facilitate first-grade changes

- Air pressurized headbox ensure uniform velocity condition

- Microfinish to the inner surface

- Micro travel adjustable League opening innovative shower for home cleaning

- Easily accessible inside area to ensure effective cleaning

2. Pope Reel Automation

Deployment benefits

Broke Reduction:

Controlled Primary & Secondary arm reeling for reduction of broke especially at Tambour roll diameters

Continuous Break free Production:

Seamless & Smooth cyclic transition of reeling from Primary arm to Secondary arm & back to Primary through automated Reel Turn up controls

Ensure Winder optimum performance:

Trouble & break free subsequent winding performance

- For Hydraulic / Pneumatic actuated pope reels

- Automated reel spool transfer from overhead spool magazine

- Integration of Gooseneck/ Tape reel turn-up systems

- Programmable Automatic nip pressure profiling controls during reeling at Primary and secondary arms Programmable automatic paper tension controls during reeling at Primary and secondary arms Automatic sequential control for change over from Primary arm reeling to secondary arm

- Nip pressure and paper Tension control through load cell feedback or computational methodology PLC-based controls

- Total safety engineering & controls included

3. Mill Winders

- Machine widths — 2500 mm to 6000 mm Machine Speed — 1500 — 2000 mpm

- Differential Torque controlled Twin drum AC drives

- Automated diameter based Nip Relieving

- Torque Nip Tension (TNT) Winding

- Automatic Unwind Pneumatic drum brake/ Regenerative motorized Load cell feedback or Computational diameter tension controls

- Total machine automation

- Empty reel spool ejection for fast change over

4. Salvage Rewinders

- Machine widths — Upto 2200mm Machine Speed — 1000 mpm

- Differential Torque controlled Twin drum AC drives

- Automated diameter based Nip Relieving

- Torque Nip Tension (TNT) Winding

- Unwind Reel loading with Overhead

- Automatic Unwind Pneumatic drum brake/ Regenerative motorized Load cell feedback or Computational diameter tension controls

- crane or Floor pickup options for fast change over

- Surface winding and Centre winding technology options

- Total machine automation

5. Synchronous - On The Fly Sheeters

- Floor pickup unwind stands with turret unwinding and auto splicing options

- Automatic Tension controls through Pneumatic disc brakes & electronic controls -in Load cell feedback as well as diameter computational options

- Automatic instantaneous unwind diameter based Decurling section.

- Option to add splice detection sensors with reject gate feature

- Inline tangential shear slitters section speed synchronized to machine speed

- Direct servo motor driven cutter drums with special cam profile motion control algorithm Machine synchronized gapping, overlapping conveyor sections with automatic layboy section. Sheet counting with automatic tag insertion options

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Shekhar Desarda

- Address

- 28 Parason House, Anukrupa, No.28, Venkatesh Nagar, Aurangabad 431001 INDIA

- Product Category

- Paper Processing Machines Parts,Paper Product Machines

- Year Established

- 1977

- No. of Total Employees

- 501-1000

- Company introduction

-

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977.

Parason is focused on Research & Development. Many researches done by Parason shown that latest technology proposed by Parason not only enables Paper Mills to increase its Paper quality but also reduces huge power consumptions of machines which is the key point of Profit for Paper Industry. Parason offered products are widely used by Kraft, Tissue, Writing Printing and Hard Board Paper Mills. Parason also have specialization in Refiner Discs and these are one of best disc available for Paper mills across the globe. Parason manufactures various products which can be used for number of operations in stock preparation.

Parason have global consultancy services, which supports organization to setup New Paper Mills and also helps existing Paper Mills to archive higher goals. Parason also have international consultants based in Germany, Europe and USA.

Parason have worldwide client base and having majority market in Germany, USA, France, Thailand, Italy, Brazil, Spain, Portugal, Philippines, Indonesia, and Bangladesh, Parason serving more than 60 countries across world. Parason has successfully completed many installations for Paper Mills ranging from 25TPD to 400TPD.

- Main Product

India

India