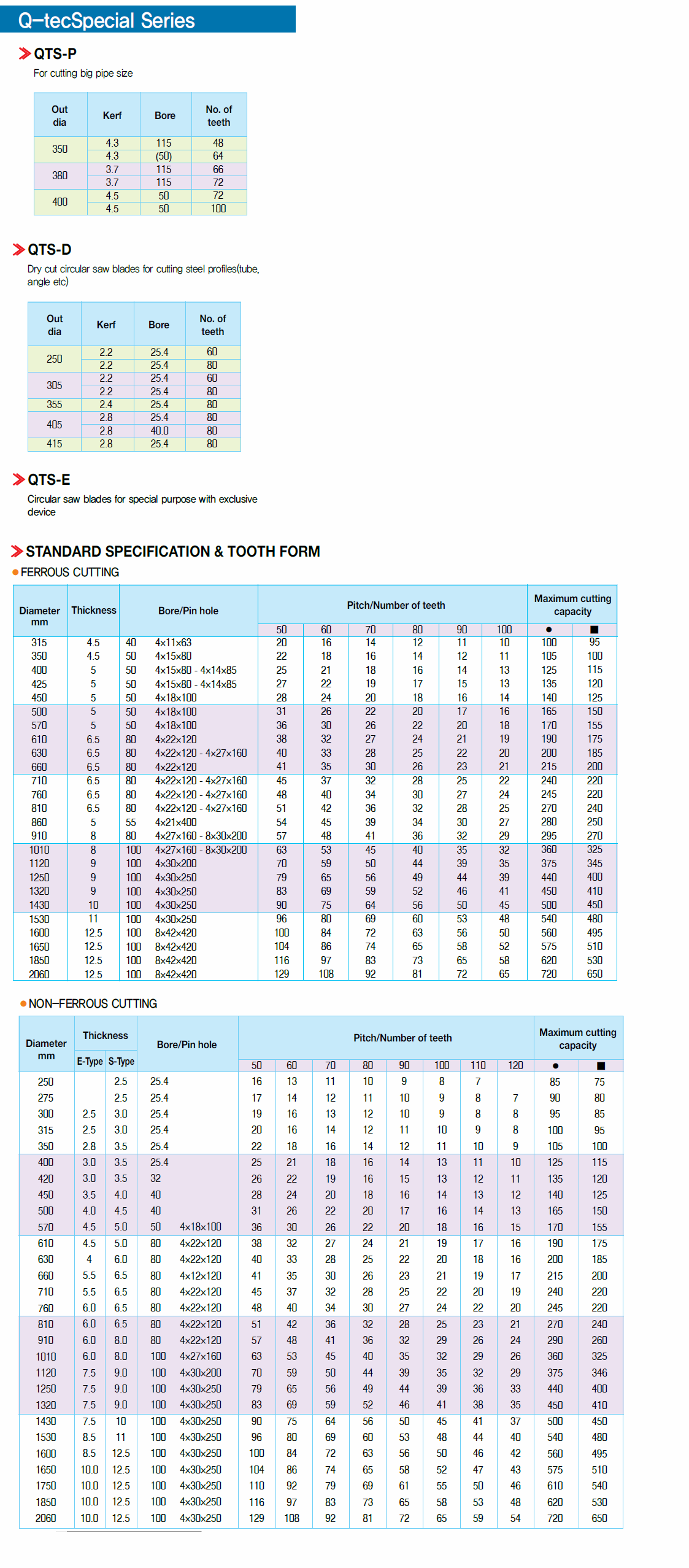

TCT Circular Saw Blade

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- DCM

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cermet, cold saw, tct, tct saw blade

- Category

- Machinery Tools , Power Saws

Duckmyung Co., Ltd.

- Verified Certificate

-

16

| Product name | TCT Circular Saw Blade | Certification | - |

|---|---|---|---|

| Category |

Machinery Tools

Power Saws |

Ingredients | - |

| Keyword | cermet , cold saw , tct , tct saw blade | Unit Size | - |

| Brand name | DCM | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8202391000 |

Product Information

The TCT Circular Saw Blade developed by Duck Myung Co., Ltd. is a wide range product suitable for all steel industries. Cemented carbide (HM) is a hard alloy made of carbide powder of metal and has excellent abrasion resistance and proper toughness. It is excellent for cutting non-ferrous metals such as aluminum and brass as well as various carbon steels.

Cermat is an alloy produced by synthesizing ceramic molecules and high-temperature resistant metal oxides such as cobalt, nickel, aluminum, and tungsten. It has higher hardness than ordinary cemented carbide, so it has excellent cutting ability at high temperatures and can maintain a high-quality surface to get a very long tool life.

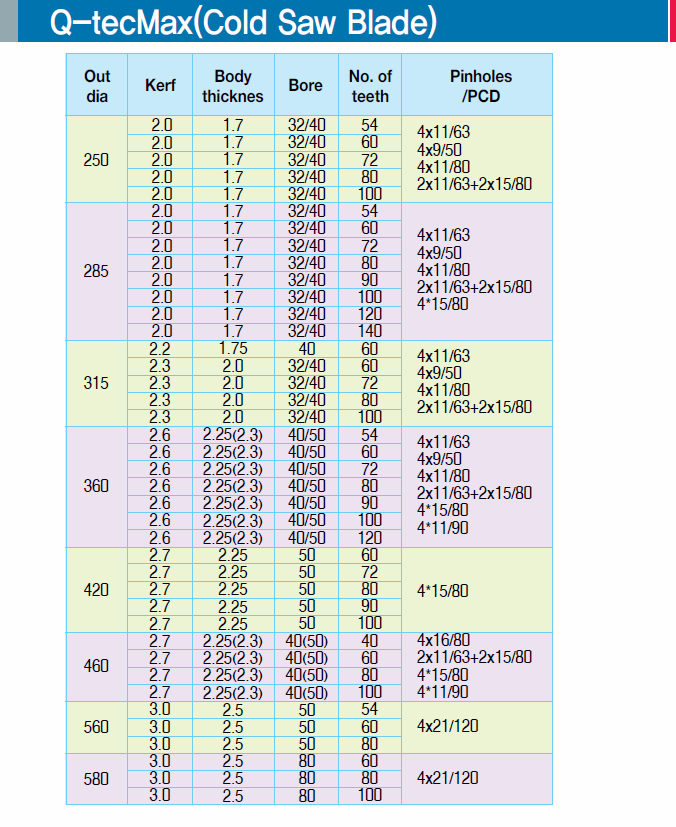

*Type of TCT Saw Blades

1)Q-Tec Max

● For cutting Carbon Steel Solid Bar

● For cutting Stainless Steel Solid Bar

● For cutting Carbon Steel Tube

● For cutting Stainless Steel Tube

● For cutting Carbon Steel Sheet

● For cutting Stainless Steel Sheet

2) Q-Tec Special – P

● For cutting pipe as flying blade

● For cutting pipe as single blade (bead and non-bead)

3) Q-Tec Special – D

● TCT Dry Cutter

4) Q-Tec Special – E

● Customized TCT Saw Blade

QTM STS 2.0 is characterized by excellent wear resistance, long tool life, and high precision for smooth cutting. It is possible to improve the working environment with low noise and realize cost reduction with high performance cutting quality.

Surface treatment

None

Application

Carbon and alloy steel rods

Cutting Parameter

Vc : 70~130m/min fz : 0.04~0.08㎜/T

QTM SUS 2.0 is a saw blade suitable for stainless steel classified as a difficult-to-cut material. It has the advantage of improving the heat resistance and abrasion resistance with PVD coating of 2~3㎛, and reducing the cutting load with a precise tooth structure to obtain optimal surface roughness.

Surface treatment

High quality PVD coating

Application

SUS304, SUS316 BILLETS

Cutting Parameter

Vc : 50~100m/min fz : 0.04~0.06㎜/T

QTM STT 2.0 is a saw blade suitable for cutting steel pipes. It is designed to minimize breakage by chips inside the pipe and reduce vibration to ensure long life.

Surface treatment

NONE

Application

Carbon and alloy steel pipes

Cutting Parameter

Vc : 100~150m/min fz : 0.03~0.09㎜/T

QTM SUT 2.0 is designed for easy chip evacuation with a saw blade for cutting stainless steel pipes, reducing cutting loads and improving cutting quality with precision machining for excellent surface finish. PVD Coating increases the heat resistance and wear resistance to extend the life of the tool.

Surface treatment

High quality PVD coating

Application

Stainless steel pipe, duplex pipe

Cutting Parameter

Vc : 50~70m/min fz : 0.03~0.06㎜/T

QTM STP 2.0 is the saw blade for cutting steel sheet can reduce the heat build-up, fatigue and cutting load of the saw blade due to continuous cutting operations, thereby increasing the service life and improving the cutting surface roughness to reduce the cost for secondary machining.

Surface treatment

None

Application

Carbon steel, alloy steel, mold steel sheet

Cutting Parameter

Vc : 70~130m/min fz : 0.03~0.1㎜/T

QTM SUP 2.0 is a product that improves the tool life by increasing the stiffness of the saw by cutting PVD with a saw blade for cutting stainless steel plates and minimizing the material fusion phenomenon that occurs when cutting stainless steel.

Surface treatment

High quality PVD coating

Application

Stainless sheet

Cutting Parameter

Vc : 50~70m/min fz : 0.03~0.06㎜/T

QTS P is a saw blade designed to improve heat resistance and wear resistance by applying PVD coating with a flying saw used for pipe line, and to minimize blade damage due to chips inside the pipe.

Surface treatment

High quality PVD coating

Application

Carbon steel pipe, stainless steel

Cutting Parameter

Vc : 170~500m/min fz : 0.03~0.2㎜/T

QTS-P Bead is a flying saw which applies to tube milling line to improve heat resistance and abrasion resistance via PVD coating. It is developed to remove the pipe's inner beads line readily.

Surface treatment

High quality PVD coating

Application

Carbon steel pipe, Stainless

Cutting Parameter

Vc : 300~500m/min fz : 0.03~0.08㎜/T

QTS-P Orbital is used in pipe making facilities and is a saw blade that cuts along the outer track of the pipe in such a way that two or four saws cut simultaneously. It is a saw blade that improves heat resistance and wear resistance by PVD coating.

Surface treatment

High quality PVD coating

Application

Carbon steel pipe, stainless steel pipe

Cutting Parameter

Vc : 350~600m/min fz : 0.04~0.12㎜/T

QTS-D has a superior cutting abilities in adverse condition such as continuous impulsion, non lubricants circumstance and insecure cutting conditions.

Surface treatment

None

Application

low carbon steel pipe, profile and various shapes of steels

Cutting Parameter

Vc : 1000 ~ 1200 m/min fz : 0.01~0.06㎜/T

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Young-moon An

- Address

- 110-50, Hyojagak-ro, Seosin-myeon, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Construction Tools,Machinery Tools,Power Tools

- Year Established

- 1983

- No. of Total Employees

- 1-50

- Company introduction

-

DUCK MYUNG (DCM) offers various circular saw blade for cutting steel and non-ferrous steel from 1983. DCM succeeded to localize HSS circular saw blade, and develop Friction saw blade, TCT saw blade, Cold saw blade, slitting saw blade and various knives. We offer various saw blade as customer`s request and cutting condition.

DCM is offering foreign countries customers as well as domestic customers satisfied product through know-how accumulated for 27 years.Head office of DCM is located in Bucheon city, and Second factory is located in Gyeongju city. As well as, has Honam service center, Sihwa service center and Busan office.

So we can offering quick and correct service to all customer through whole country. DCM has agency in Singapore, Vietnam, China and is offering many customers product of excellent quality to Indonesia, Malaysia, Japan, Poland, U.A.E. DCM does lively activity such as academic-industrial cooperation , Frontier enterprise, Inno-Biz and hold many patent and utility model, trademark right etc.. as well as keep constant technical development and qualification of ISO 9001 that is international standard by thorough quality control.

- Main Markets

-

Czecho Republic

Czecho Republic

Hong Kong(China)

Hong Kong(China)

Indonesia

Indonesia

Japan

Japan

Malaysia

Malaysia

Thailand

Thailand

Turkey

Turkey

U.A.E.

U.A.E.

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea

_2.jpg)