HSS Circular Saw Blade

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- hss saw blade, saw, high speed saw blade, hss

- Category

- Machinery Parts , Power Saws

Duckmyung Co., Ltd.

- Verified Certificate

-

16

| Product name | HSS Circular Saw Blade | Certification | - |

|---|---|---|---|

| Category |

Machinery Parts

Power Saws |

Ingredients | - |

| Keyword | hss saw blade , saw , high speed saw blade , hss | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8202310000 |

Product Information

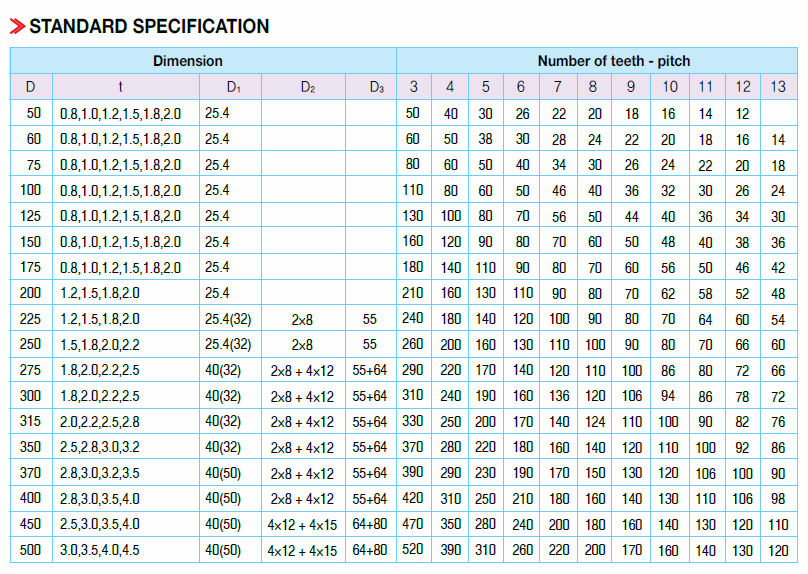

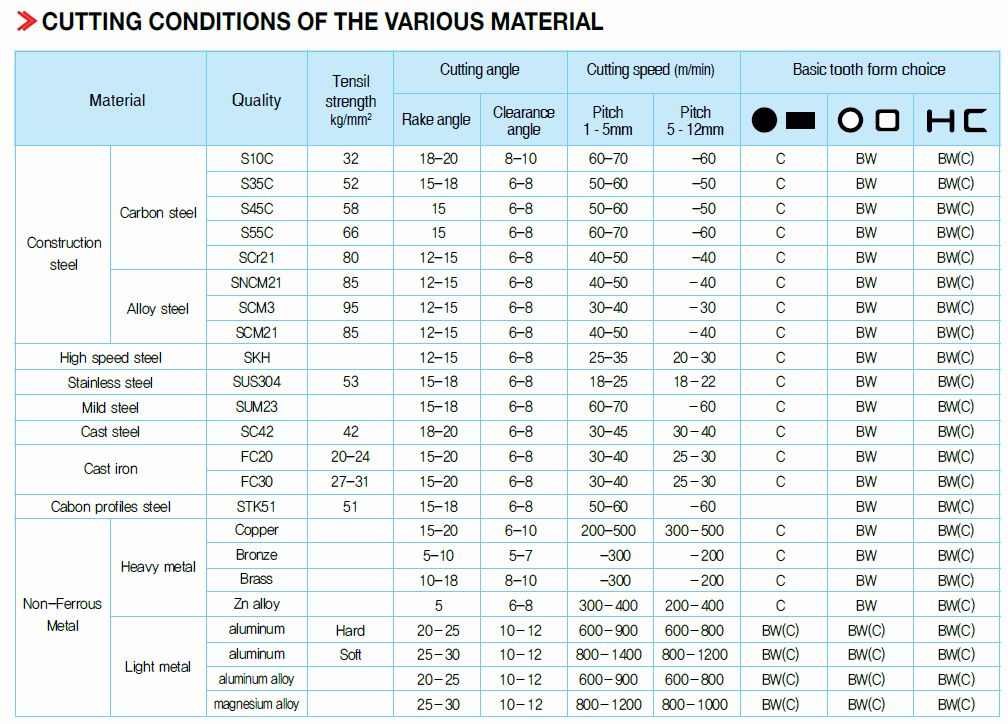

Duck Myung Co.,Ltd (DCM) can produce HSS Circular Saw Blade from OD 50mm to 550mm and are classified into 5 tooth form and 5 coatings depending on the cutting materials and application. The High Speed Steel for this product is divided into Molybdenum and Cobalt grade. The Molybdenum grade has low brittleness, high toughness, and high wear resistance, so it is highly versatile and you can expect high tool life and cutting quality with proper coating.

Cobalt grade has almost similar chemical component but it is excellent for cutting materials with high mechanical resistance such as high tensile strength steel and stainless steel because it has an excellent heat resistance and high hardness.

Based on these factors, DCM selects the best saw parameters according to the customer's requirements and cutting environment and then produces BEST QUALITY HSS Circular saw blade for our customers.

HSS-ST is a standard product considering the economics of the tool, it is mainly used for manual and semi-automatic saw machines. It is occasionally applied for cutting structural steel and non-alloy steel, and is appropriated for continuous cutting of non-ferrous metals such as aluminum and brass.

Surface treatment

Bright / Steam Homo

Application

Non-ferrous metals, structural steel, non-alloy steel

Cutting Parameter

Vc : 30-50m/min(for cutting steel)

HSS-EX is able to increase a productivity and extended tool life via special geometry and increasing surface density with 2~4µm Titanium PVD(Physical Vapor Deposition) coating hereby superior coefficient of friction can help tool’s wear resistance. It is usually used for cutting tubes and profiles at high speed. It is advantageous for cutting structural steel and stainless steel. Both manual, semi-automatic and automatic machines available.

Surface treatment

Titanium nitrogen coating applied(TIN)

Application

structural steel, stainless

Cutting Parameter

Vc : 40-100m/min(cutting for steel)

HSS-AD is a product combining high-quality heat treatment method and PVD coating applying premium high-speed steel. It is a special purpose product produced by optimizing geometry according to the purpose of use.

Steel grades and hardness are applied differently depending on the cutting environment, machine used, and cutting material of the customer. Also, it is divided into 3 types according to the application.

HSS-TU:It brings a superior cutting surface and developed productivity(for off-line cut).

HSS-FL : It applies to on-line cut off for Electronic Resistance Welding production line.

HSS-EP : It is exclusive purpose saw blades. It is designed to surface treatment and shape according to customer’s demands.

Surface treatment

High quality PVD coating

Application

structural steel ,stainless, non-ferrous steel

Cutting Parameter

Vc : 50-250m/min(cutting for steel)

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Young-moon An

- Address

- 110-50, Hyojagak-ro, Seosin-myeon, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Construction Tools,Machinery Tools,Power Tools

- Year Established

- 1983

- No. of Total Employees

- 1-50

- Company introduction

-

DUCK MYUNG (DCM) offers various circular saw blade for cutting steel and non-ferrous steel from 1983. DCM succeeded to localize HSS circular saw blade, and develop Friction saw blade, TCT saw blade, Cold saw blade, slitting saw blade and various knives. We offer various saw blade as customer`s request and cutting condition.

DCM is offering foreign countries customers as well as domestic customers satisfied product through know-how accumulated for 27 years.Head office of DCM is located in Bucheon city, and Second factory is located in Gyeongju city. As well as, has Honam service center, Sihwa service center and Busan office.

So we can offering quick and correct service to all customer through whole country. DCM has agency in Singapore, Vietnam, China and is offering many customers product of excellent quality to Indonesia, Malaysia, Japan, Poland, U.A.E. DCM does lively activity such as academic-industrial cooperation , Frontier enterprise, Inno-Biz and hold many patent and utility model, trademark right etc.. as well as keep constant technical development and qualification of ISO 9001 that is international standard by thorough quality control.

- Main Markets

-

Czecho Republic

Czecho Republic

Hong Kong(China)

Hong Kong(China)

Indonesia

Indonesia

Japan

Japan

Malaysia

Malaysia

Thailand

Thailand

Turkey

Turkey

U.A.E.

U.A.E.

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

Related Products

KBC Bearing

Diamond Tools: Diamond Blade, Diamond Polishing Pads, Diamond Grinding Wheel, Diamond Wire Saw

FR Coating

UIM2901-5A MACH3 break out board for CNC

yacht fittings

South Korea

South Korea