Filter Needle Assembly Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Jushin Machinery

- Verified Certificate

-

5

| Product name | Filter Needle Assembly Machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | medical appliances , filter needle assembly , filter needle assembly machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

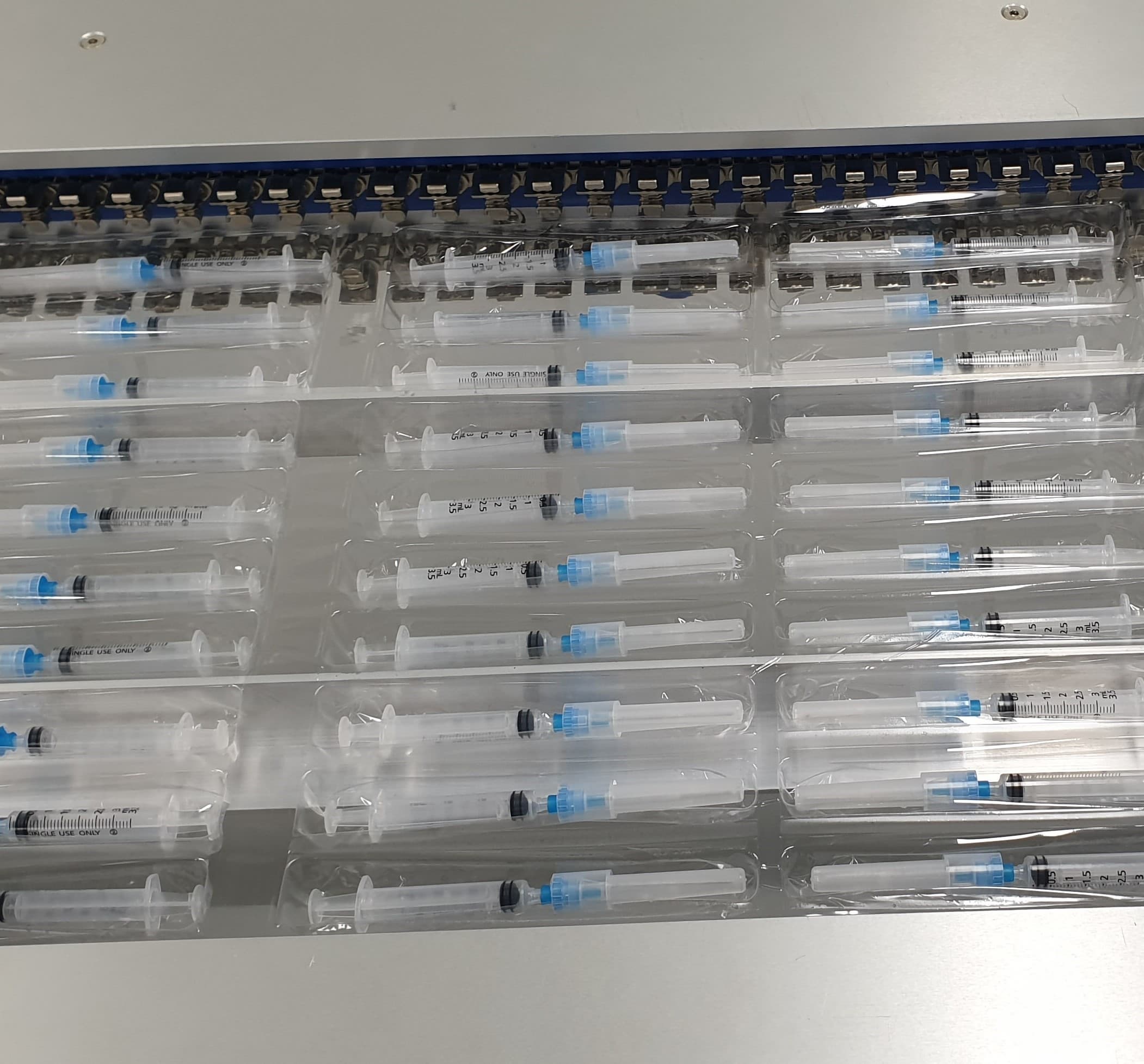

1. Machine Summary - assembly of filter teeth. The components are supplied with injection materials (parts) and the assembly of the filter teeth is produced through assembly, inspection and discharge processes.

2. Machine specification

1) Mechanical specification - W:4,000 mm , L:5,700 mm , H: 1,650 mm

2) Mechanical weight - 2000 kg

3) Mechanical material - Aluminum , Stainless

4) Electrical specification - 380V / 3, 220V / Single phase 5)

5) Power consumption - approx. 10 kw / 20A

6) Air consumption - approx. 100L / min

7) Vacuum consumption - 250L / min

3. Machine Part

1) Product Supply (Feeder) - Product (Injection) Supply

2) Vision System - Qualifying goods/defective goods and collecting data

3) Ultrasonic Welder - Momentarily folds the product without the need for adhesives/solvents due to ultrasonic vibrations

4) Product JIG

5) Transfer conveyor (Conveyor)

6) Defective/Completed discharge conveyor, etc.

- joosin machinery co. -

1. Machine Summary - assembly of filter teeth. The components are supplied with injection materials (parts) and the assembly of the filter teeth is produced through assembly, inspection and discharge processes.

2. Machine specification

1) Mechanical specification - W:4,000 mm , L:5,700 mm , H: 1,650 mm

2) Mechanical weight - 2000 kg

3) Mechanical material - Aluminum , Stainless

4) Electrical specification - 380V / 3, 220V / Single phase 5)

5) Power consumption - approx. 10 kw / 20A

6) Air consumption - approx. 100L / min

7) Vacuum consumption - 250L / min

3. Machine Part

1) Product Supply (Feeder) - Product (Injection) Supply

2) Vision System - Qualifying goods/defective goods and collecting data

3) Ultrasonic Welder - Momentarily folds the product without the need for adhesives/solvents due to ultrasonic vibrations

4) Product JIG

5) Transfer conveyor (Conveyor)

6) Defective/Completed discharge conveyor, etc.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Kim Suen Jong

- Address

- Darwolgil 49 3, Siheung-si, Gyeonggi-do, Korea

- Product Category

- Pharmaceutical Machinery

- Year Established

- 2017

- No. of Total Employees

- 1-50

- Company introduction

-

Hello!

Genetic machinery will be the basis of all industries in the world today, past, and tomorrow, in the fourth industrial era.

We are always committed to our best efforts and best technology, aiming at global companies leading the global market in the machinery manufacturing sector, which is the foundation of all industries.

Since its foundation, it has developed and manufactured various medical devices and industrial facilities.-joosin ceo-

- Main Product

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)