zirconia fused alumina/ZA/aluminum oxide for polishing

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Henan Sicheng Abrasives

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasives

Henan Sicheng Abrasives Tech Co.,Ltd

- Membership

- BIZ

- Recent Visit

- Jan 10, 2025

- Country / Year Established

-

China

/

2010

China

/

2010

- Business type

- Manufacturer

- Verified Certificate

-

7

| Product name | zirconia fused alumina/ZA/aluminum oxide for polishing | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | fused alumina , zirconia fused alumina , za40% zirconia fused alumina | Unit Size | - |

| Brand name | Henan Sicheng Abrasives | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

zirconia fused alumina/ZA/aluminum oxide for polishing and grinding

production introduction

Zirconia Fused Alumina

Zirconia fused alumina is produced by putting rich aluminum, zirconium materials and additives in electric furnace, smelting with high temperature above 2000°C,cooling down with special technology, and compacting with Barmac plastic, which has the characteristics of tenacious texture, dense structure and high strength.

This product is not a kind of aenoir abrasive, but can be also used as highgrade refractory. It takes the advantages of high strength, high toughness, high temperature resistance, which can manufacture heavyduty wheel with high performance, and has achieved very good results in grinding steel, cast iron, heatresistant steel, titanium alloys, aluminum alloys and tungsten alloy. And it is widely used in the production of refractoriness in the steel industry such as continuous casting and rolling, flow channel, and glass kin as well.

It is a kind of high grade abrasive and refractory materials, with the characteristic of high intensity, high toughness and high selfsharpness. The most common applications are in high pressure grinding wheels and pressure blasting of very hard surfaces. It is classified into ZA 25 and ZA 40 as the content of Zr02.

Product Parameters

| Al2O3 | ZrO2 | SiO2 | TiO2 | Fe2O3 | |||

ZA25 | >70 | 23-26 | <0.4 | <0.5 | <0.3 | |||

ZA40 | >56 | 38-41 | <0.4 | <0.4 | <0.2 | |||

Gnit designation |

Rangeof BulkDensity |

Gnit designation | Rangeof BulkDensity | |||||

ZA | ZAN | ZA | ZAN | |||||

F8 | 2.32-2.24 | 2.38~2.34 | F46 | 1.98~1.90 | 2.05~1.96 | |||

F10 | 2.26-2.19 | 2.32~2.34 | F54 | 1.96~1.88 | 2.03~1.92 | |||

F12 | 2.24-2.16 | 2.30~2.26 | F60 | 1.94~1.86 | 2.00~1.88 | |||

F14 | 2.19~2.14 | 2.28~2.24 | F70 | 1.92~1.83 | 1.97~1.85 | |||

F16 | 2.18~2.12 | 2.24~2.18 | F80 | 1.89~1.81 | 1.94~1.83 | |||

F20 | 2.16~2.03 | 2.21~2.15 | F90 | 1.86~1.80 | 1.91~1.81 | |||

F22 | 2.13~2.02 | 2.18~2.12 | F100 | 1.83~1.77 | 1.88~1.79 | |||

F24 | 2.10~2.00 | 2.15~2.09 | F120 | 1.80~1.74 | 1.85~1.76 | |||

F30 | 2.06~1.97 | 2.12~2.06 | F150 | 1.78~1.71 | 1.82~1.73 | |||

F36 | 2.02~1.95 | 2.10~2.04 | F180 | 1.78~1.68 | 1.80~1.70 | |||

F40 | 1.99~1.93 | 2.08~2.01 | F220 | 1.75~1.64 | 1.78~1.70 | |||

|

|

|

|

|

|

|

|

|

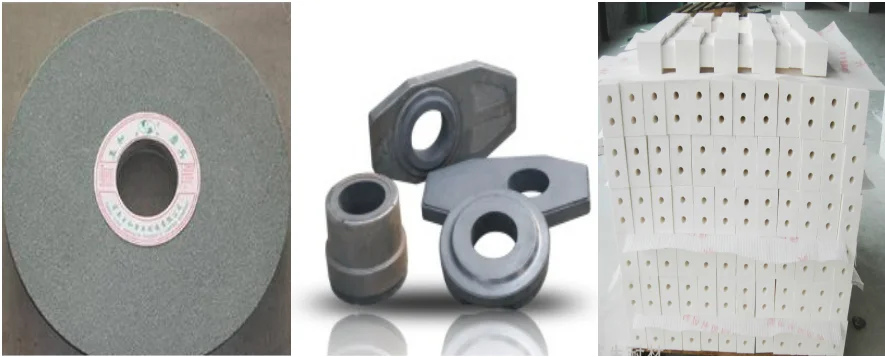

Applications

Zirconia Fused Alumina can tolerate melt erosion. As a senior abrasive, it can be used in high performance of heavy-duty wheel manufacturing, and have good grinding effect on steel, cast iron, heat-resistant steel, and various alloys ; In addition, zirconia Fused Alumina is a high-grade refractory materials,and its an ideal material for manufacturing high performance sliding nozzle and immersion nozzle, can also be used for the production of glass melting furnace with zirconium corundum brick.

Why Choose Us

Henan Sicheng Abrasives Tech Co., Ltd is a manufacturer of abrasives and refractories with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in steel metal smelting,abrasive tools,surface treatment,polishing and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Contact us

Mob 008618236795218

Whatsapp + 86 18236795218

Wechat 18236795218

Skype krystal Dai

About us

Henan Sicheng Abrasives Tech Co., Ltd the manufacturer, is a comprehensive joint-stock company integrating production, R&D and trade.Our products mainly include WHITE FUSED ALUMINA,BROWN FUSED ALUMINA,SLICON CARBIDE ,GLASS BEADS etc.Primarily export to East Asia, Southeast Asia, Europe, The americas, Middle East, Australia and Africa etc .Our company gets a good reputation for our best quality and service.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Feng Lingzhou

- Address

- ROOM 1409, #1 BUILDING, LVDI CENTRE, DAXUE SOUTH ROAD, ZHENGZHOU, CHINA

- Product Category

- Abrasives

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

Henan Sicheng Abrasives Tech Co., Ltd, is a leading exportor and manufacturer of chromite sand & Chromite powder from China.

- Main Product