Injection Molding Machine for Automatic Hoop Insert Molding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

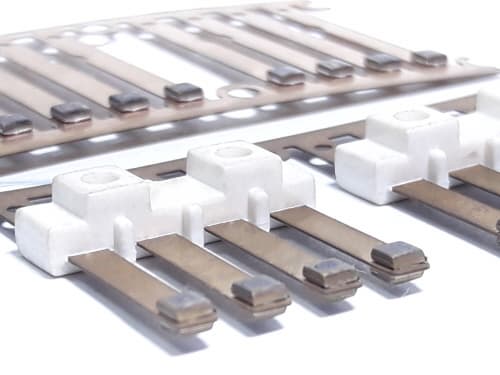

- hoop insert molding, automatic insert molding machine, automatic insert molding system of relay connector, automation of insert molding

- Category

- Plastic Product Making Machinery

i-SSAN Engineering

- Verified Certificate

-

13

| Product name | Injection Molding Machine for Automatic Hoop Insert Molding | Certification | - |

|---|---|---|---|

| Category | Plastic Product Making Machinery | Ingredients | - |

| Keyword | hoop insert molding , automatic insert molding machine , automatic insert molding system of relay connector , automation of insert molding | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

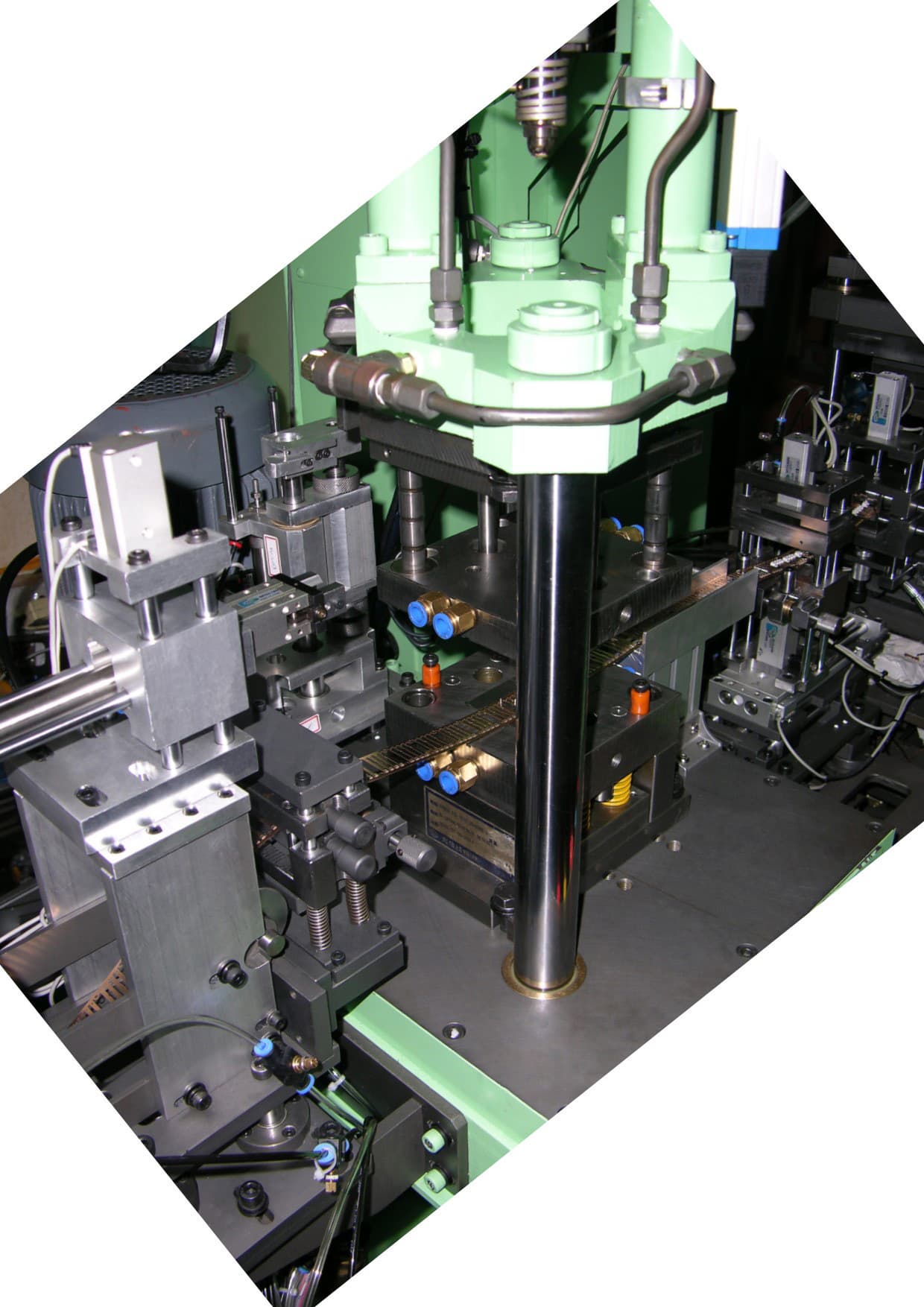

Model : JD-HIM-30-FA

Components : Bobbin station

: Injection molding machine-Vertical

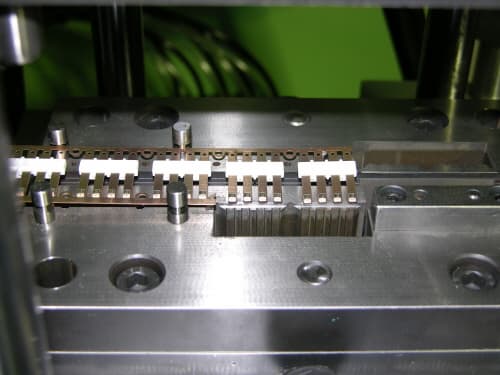

: Insert Mold

: Sprue Take-out Robot

: Feeding Robot

: Press Cutting Station

: Press mold

: Auto Loader of Rawmaterial

: Temperature Controll unit (embeded)

: Micro Chiller (embeded)

: HMI control system

General Description

JD-HIM-30-FA is consisted with fully automatic working device of Insert Molding & Press cutting.

System is built up by major 3 section as below.

①Material Handling,

② Injection Molding machine,

③Cutting Press machine

It's most optimized design process for mass production for Hoop Insert molding business.

At the final discharge shut, we just got the products and scraps separately.

Various type of tunning device will make it easy to align hoop flow and set the whole system.

This Micro plant-most compact sized but have fluent function for speccial process-will give

lots of advantage for your business.

① Can be installed any place.

-Moved by Caster

② Required Very small installation Area,

③ Easy operation through HMI

④ All of Utility embedded

⑤ Quick Setting And Aligning Hoop flow.

Model : JD-HIM-30-FA

Injection Volume : 30cc

Hydraulic Unit : 2 set

Barrel heater control : Embedded

Mold heater control : Embedded

Micro Chiller fpr Hooper Cooling : Embedded

Oil Cooler : Installed

Press : 20 Ton

Bobbin Station : 1 set

Hoop entrance Jig : 1 set

Auto Loader : 1 set

Sprue Take-out Robot : 1 set

Pitch control (feeding) Robot : 1set

Machine Size : Width 3 meter

Depth 1.2 meter

Hight 2.5 meter

Installation Area : 3.5meter x 4.5meter ( 16 m2 )

Operation : Interface through Touch Screen

Specialized for : Hoop Molding with Full Automatoc Operation

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Minho Kim

- Address

- 356-10, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Medical Consumables,Molds,Other Rubber Products,Plastic & Rubber Machinery Parts,Plastic Product Making Machinery

- Year Established

- 2018

- No. of Total Employees

- 1-50

- Company introduction

-

Business Scope

▷ Mold making

▷ Injection & Extrusion equipments

▷ Automation

▷ R&D

▷ Plant, System Engineering

Business Items

Machineries, Tools, Special Equipments that we make;

① Plastic Injection Molding machines

② LSR Injection molding Machines

③ PIM machineries (with related material handling equipments)

④ CNC Injection molding machines ( Full Automation )

⑤ Special Injection molding machine (LED, Slipring, Relay Connector)

⑥ Extruder,

⑦ Automatic Injecton Molding system

⑧ Specilized/Customized for Ultra Micro & Precision Injection molding sysm.

(LSR, Artificial Eyeball)

Software Service:

Design & Developing manufacturing process of New Materials related

with Injection, extrusion and press technologies.

① New materials of Polymers

② Nano- Powders (Metal, Ceramic),

③ Liquid Silicon Rubber(LSR)

Engineering consulting:

① Part design & Modeling (2D, 3D),

② Process Developing,

③ Plant Engineering.,

Mold Making Service(Specialized)

① Plastic Mold,

② PIM, PICM, PIM2K, PICM2K (Functional Mold for PIM)

③ LSR Mold

Special System (Micro Plant)

① Automatic LED module production system,

② Automatic Relay connector insert molding system,

③ Surgical Anchor (Screw) production system (Biodegradable resign),

④ Artificial Eyeball parts (LSR),

⑤ CNC Injection molding machine.

Special Producing items

① Medical Comsumables : Sutute Anchor (Peek & Biodegradable materials)

② Artificial Organ : Artificial blood vessel (Teflon)

: Artificial Eyeball (LSR)

③ Menstrual Cup (LSR)

④ Industrial Parts

⑤ Cushiion seat of Egg tray(LSR)

- Main Markets

-

South Korea

South Korea

- Factory Information

-

I-SSAN ENGINEERING

- Main Product