Coil Shock Absorber Transport System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Rubber Products

K2 JOINT KOREA Co.

- Verified Certificate

-

12

| Product name | Coil Shock Absorber Transport System | Certification | - |

|---|---|---|---|

| Category | Rubber Products | Ingredients | - |

| Keyword | coil storage pad , stee coil rests , stee coil prop , a stee coil stand | Unit Size | 294.0 * 300.0 * 160.0 mm |

| Brand name | - | Unit Weigh | 110 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 0101299000 |

Product Information

Coil Steel Transportation on the road

Conventional transportation systems for coil steel are air cushion system at the trucks, specific functions absorbing the shock to the coil steel with wood or rubber plate, etc. They can not absorb the force and repulsion generated when it is transported and especially in case of emergency like a sudden stop or sharp curve. So it is exposed to the danger all the time. And steel coil may be damaged

(plating layer black spot, caused appearance damage).

K2Jointkorea Company, recently, developed own unique system, “Rubber Cushion Pad for Steel Coil’s Transport“. It is designed to absorb the forces generated when it is transported on the basis of safety.

Coil Steel Loading Safety Device

Conventional transportation systems for coil steel are the methods of placing angle, wood, rubber plates, etc. on the bottom of vehicle‘s loading surface and putting coil on those plate and commonly used throughout the world. In this case, a fixing device is used to fasten the product firmly for the safety reason, which normally cause damage to the coil steel as the steel coil’s contact area is not flat. Also with another circumstances such as friction, vibration, shock, etc. during the coil loading and transportation, the coils are supplied to the customers in the condition that the coil’s surface is damaged.

As a raw material, the coil steel is used diversely as plate for vehicle, electronic product, construction materials, etc. If such steel coils damaged during the transportation are used for the production, it may accelerate corrosion compared with the normal area.

[Features]

Coil steel is difficult to handle as it weighs at least 10 tons and is in a spherical form that may result in a safety accident. When loading such coils on vehicle or in warehouse, it is normal to adopt bearing using angle, wood, rubber plate, etc. This is accompanied by the risk of safety accident as well as damage to raw material. (plating layer black spot, caused appearance damage) Our newly developed and patented product, “Rubber Cushion Pad for Steel Coil’s Transport“, is aiming at preventing such damage to raw material or safety accident caused by the conventional transportation system. Domestic tests had been conducted to the sample vehicles of domestic steel manufacturer/transportation company from Aug. 2009 until Oct. 2010 while overseas tests to the local vehicles by the team consisting of Malaysia POSCO MKPC Branch, POSCO headquarter, Hyosung, and K2Jointkorea in September 2010. In those tests, it was approved as a differentiated and best Rubber Cushion Pad for Steel Coils Transportation. Since they were delivered to POSCO, they are now widely used in coil steel manufacturer&transportation companies. They were also delivered to Indonesia BNX Korea Branch in May 2011 and Hanoi Vietnam in Jun. 2011.

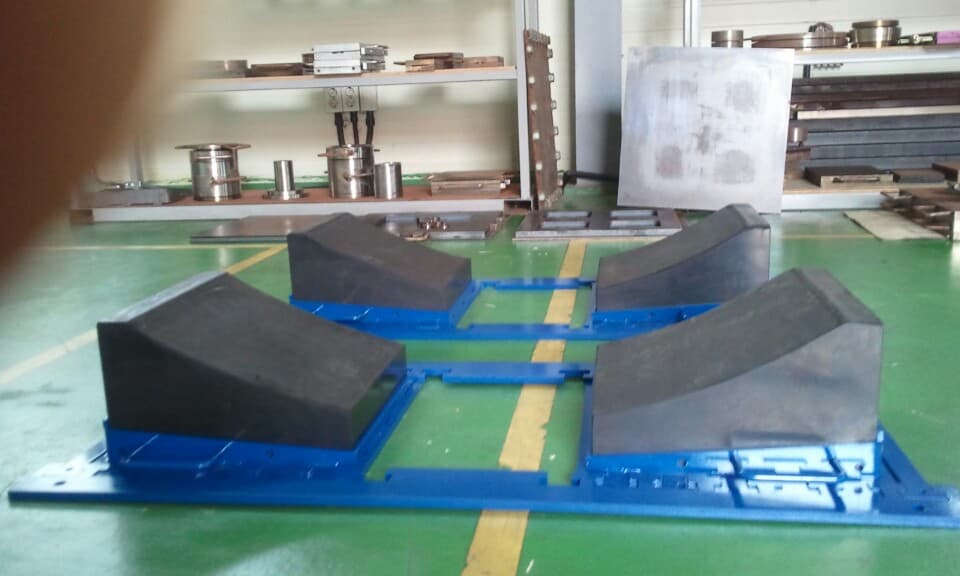

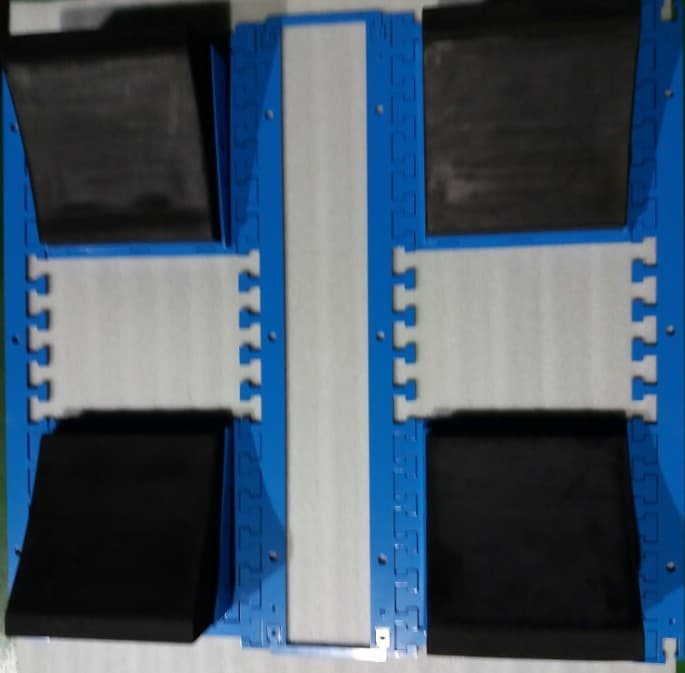

It is structured in such a manner of wrapping the coil steel with especially compounded elastomeric pad. Its contact area is plane to guarantee high safety. It basically minimizes the damage to the product. Designed to accommodate the hardness with high elastomeric pad horizontally and vertically, it is very stable and safe. The loading surface is in the form of rail that allows attachment/detachment of coil. It can be adjusted easily depending on the external diameter of steel coil in consideration of convenience and safety. It is assessed as semi-permanent product in durability.

Coil Steel Transportation on the road

Conventional transportation systems for coil steel are air cushion system at the trucks, specific functions absorbing the shock to the coil steel with wood or rubber plate, etc. They can not absorb the force and repulsion generated when it is transported and especially in case of emergency like a sudden stop or sharp curve. So it is exposed to the danger all the time. And steel coil may be damaged

(plating layer black spot, caused appearance damage).

K2Jointkorea Company, recently, developed own unique system, “Rubber Cushion Pad for Steel Coil’s Transport“. It is designed to absorb the forces generated when it is transported on the basis of safety.

Coil Steel Loading Safety Device

Conventional transportation systems for coil steel are the methods of placing angle, wood, rubber plates, etc. on the bottom of vehicle‘s loading surface and putting coil on those plate and commonly used throughout the world. In this case, a fixing device is used to fasten the product firmly for the safety reason, which normally cause damage to the coil steel as the steel coil’s contact area is not flat. Also with another circumstances such as friction, vibration, shock, etc. during the coil loading and transportation, the coils are supplied to the customers in the condition that the coil’s surface is damaged.

As a raw material, the coil steel is used diversely as plate for vehicle, electronic product, construction materials, etc. If such steel coils damaged during the transportation are used for the production, it may accelerate corrosion compared with the normal area.

Under these circumstances, manufacturers, transportation companies, and steel coil suppliers are seeking the solution of such problem. In case of using wood bearing, when the vehicle starts or stops suddenly in an emergency situation or on the sharp curve, instantaneous force of more than twice the weight of steel coil is delivered to the fixing device due to the phenomenon that loaded surface is being pushed.

Accordingly safety accidents may happen and resulting critical damages to fixing device. There is no other safety device when safety accidents happen to fixing device throughout the world, which may threaten the life of cargo owner or others.

We have developed “Stop Rubber Paper Pad” which is the safety device preventing being pushed due to steel coil’s weight using the same method of being mounted on the bottom of vehicle’s loading surface (Rubber Cushion Pad for Coils Transportation). It secures further safety.

• Adjustable steel coil OD and handling ease

• POSCO Steel Corp. approved high elastic rubber pad (K2jointkorea co. Patents)

(Heat resistance, abrasion, oil, ozone is an excellent product).

• Vehicle loading safety pad mounting (K2jointkorea co. Patents)

The logistics of raw materials to avoid damaging Vehicle, warehouses, ships, containers, train accidents special rubber company specializing in the production of products that can be prevented for heavy loads.

[Applications]

As a bearing for steel coil when loading or unloading on ship, trailer, train, container, etc.

[Specifications]

1. Model No. : JK-Csp-Rep-100 (A . B)

2. Model No. : JK-Csp-Rep-200 (A . B)

3. Model No. : JK-CSP-Rep-300 (A . B)

⦁ 4 rubber pads for one steel coil

⦁ handles 10 tons up to 100 tons based on the coil’s external diameter 1,350 mm more or less

⦁ weighs 65Kg ~ 94kg

⦁ Patent name : Loading Device with Rubber Cushion Pad Absorbing Shock to Coil Steel (Patent No. : 10-0994884)

- Fixed separation cavity ("A" , "B" Type)

1. Model No. : JK-CSP-3000Kn/RREP ("A" TYPE)

⦁ 4 rubber pads for one steel coil

⦁ handles 10 tons up to 100 tons based on the coil’s external diameter 1,350 mm more or less

⦁ weighs 100Kg ~ 110kg

⦁ Patent name : Loading Device with Rubber Cushion Pad Absorbing Shock to Coil Steel (Patent No. : 10-0994884)

- Fixed separation cavity

lmproved products safety devic

1. Model No. : JK-CSP-3000Kn/REP "B" TYPE

⦁ handles 10 tons up to 120 tons based on the coil’s external diameter 1,450 mm more or less

⦁ weighs 100Kg ~ 110kg

• Patent name : Coil steel loading safety device (Patent No. : 10-1338774)

• Advanceproof pad equipped with safety and accident prevention products

- Fixed separation cavity

Rubber Pad Load Capacity

• MAIN. : No. Steel coil full size.

• SLS Permanent Vertical Load (Kn)

• SLS Total Load (Kn)

• ULS Vertical Load (Kn)

※ A POSCO PARTNER.

A India JSW STEEL LIMITED PARTNER.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- kim do gyun

- Address

- Paltan-myeon, Yul-am-gil, 121-14 . 2-dong, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Industrial Supplies,Other Rubber Products

- Year Established

- 2000

- No. of Total Employees

- 1-50

- Company introduction

-

We have manufactured and supplied specialrubber products applicable to a variety of industrial fields such asconstruction, civil work, special constructional structure bearing,building-purpose joint, logistic/transportation loading device, outdoor, chemical,food, machinery, ship, special anti-vibration, etc. We will be devoted to continuous developmentbased on accumulated technology and experience and promise to supplydifferentiated product in construction, safety, durability, quality, andeconomy that can be applied to construction, civil work, railway bridge, etc.

Wewill develop and manufacture the world’s best product, and will be reborn asthe company that does its best.Thank you.

Kim Do-GYUN

Representative Director

- Main Markets

-

China

China

Germany

Germany

Guatemala

Guatemala

Hong Kong(China)

Hong Kong(China)

India

India

Indonesia

Indonesia

Italy

Italy

Japan

Japan

Mexico

Mexico

Netherland

Netherland

Oman

Oman

Poland

Poland

Russia

Russia

Singapore

Singapore

South Africa

South Africa

Taiwan

Taiwan

Turkey

Turkey

U.S.A

U.S.A

Ussr

Ussr

Viet Nam

Viet Nam

- Main Product

South Korea

South Korea