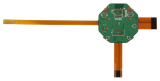

FR4 PCB Printed Circuit Board with LF HAL

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- BenQiang

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Passive Components

Shenzhen Benqiang Circuit Technology Co., Ltd.

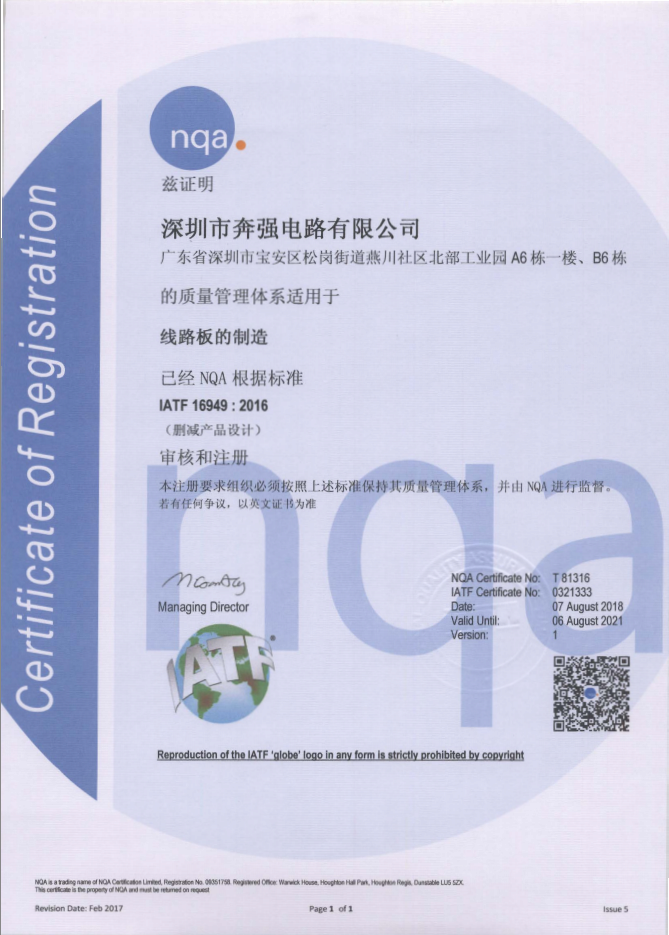

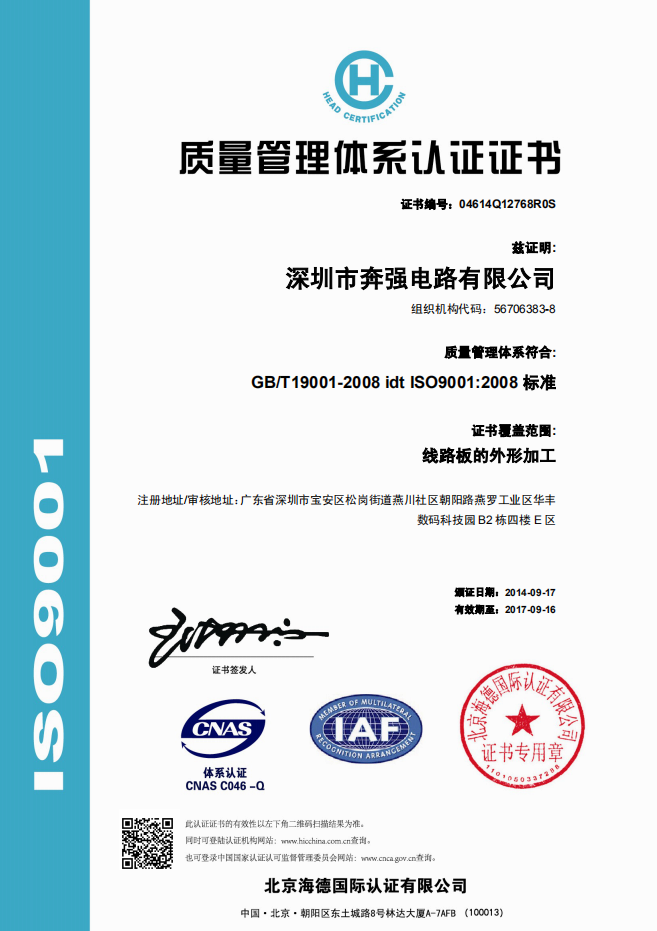

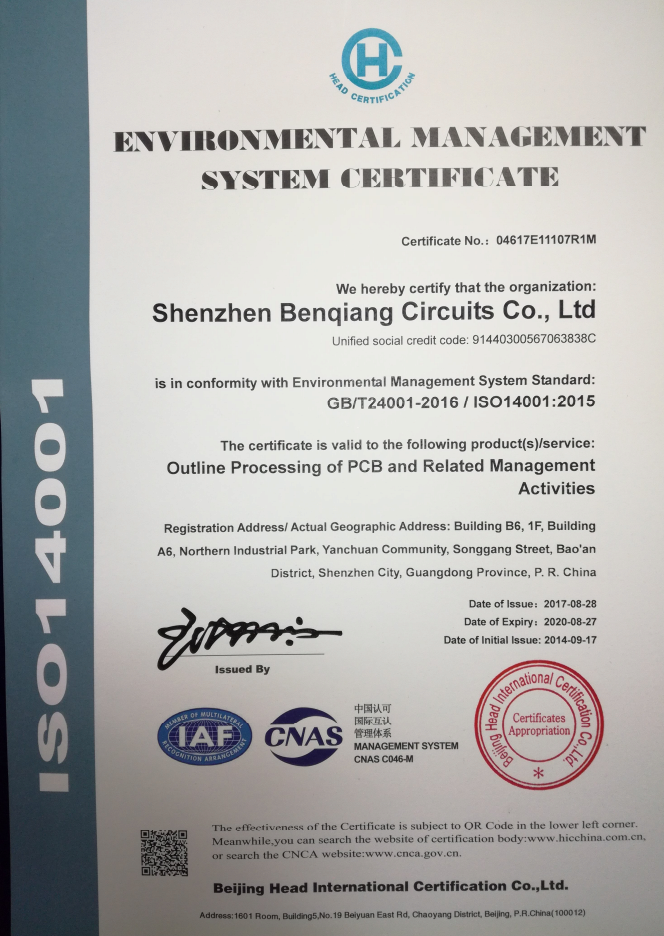

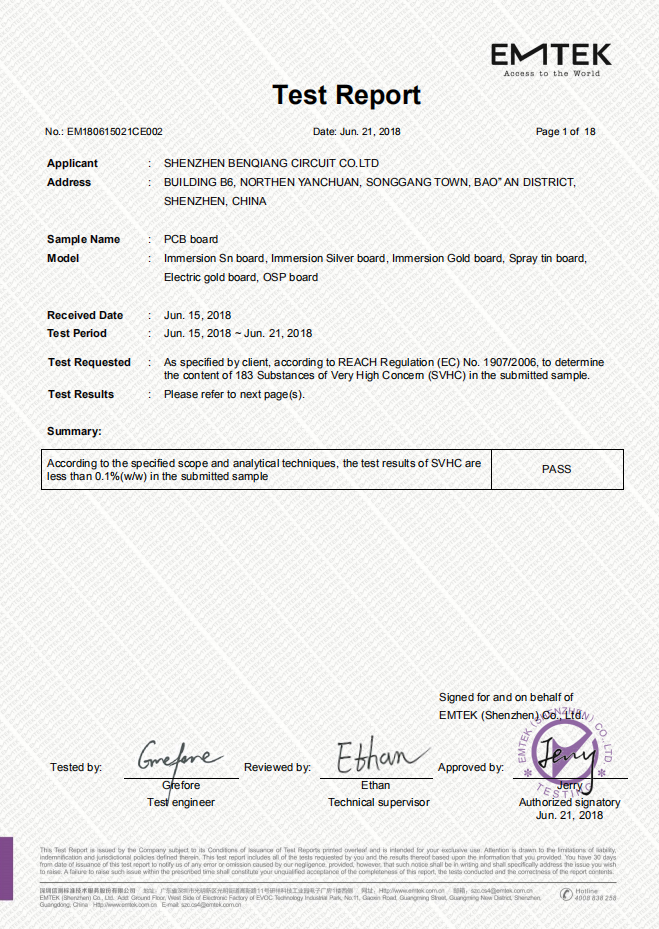

- Verified Certificate

-

6

| Product name | FR4 PCB Printed Circuit Board with LF HAL | Certification | - |

|---|---|---|---|

| Category | Passive Components | Ingredients | - |

| Keyword | printed circuit board , multilayer pcb board | Unit Size | - |

| Brand name | BenQiang | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Shenzhen Benqiang Circuit Co., Ltd. is a high-tech enterprise founded in 2005 in Shenzhen and engages in providing the most excellent and prompt service for the continuous innovation of scientific enterprises and in becoming a first-rate Chinese supplier of hardware outsourcing design service. Our PCB R&D manufacturing base is located in Shenzhen and Huizhou. Besides, we have a workshop of 80,000 square meters and more than 500 employees, 35% of whom are professional technical personnel and roughly 20% of whom have bachelor's and master's degree. So for we have set up branch offices in Beijing, Shanghai, Wuxi, Hangzhou, Wuhan, etc. and more than ten customer service centers. All these allow us to have put into place a marketing and technical service network which facilitates offering excellent and efficient service to more than 5,000 customers across the world.

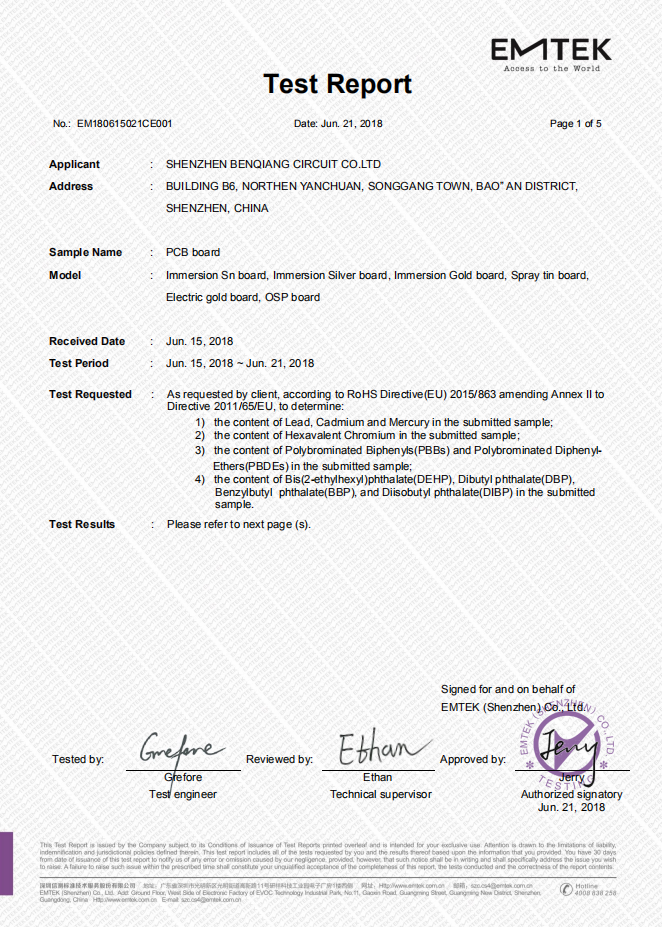

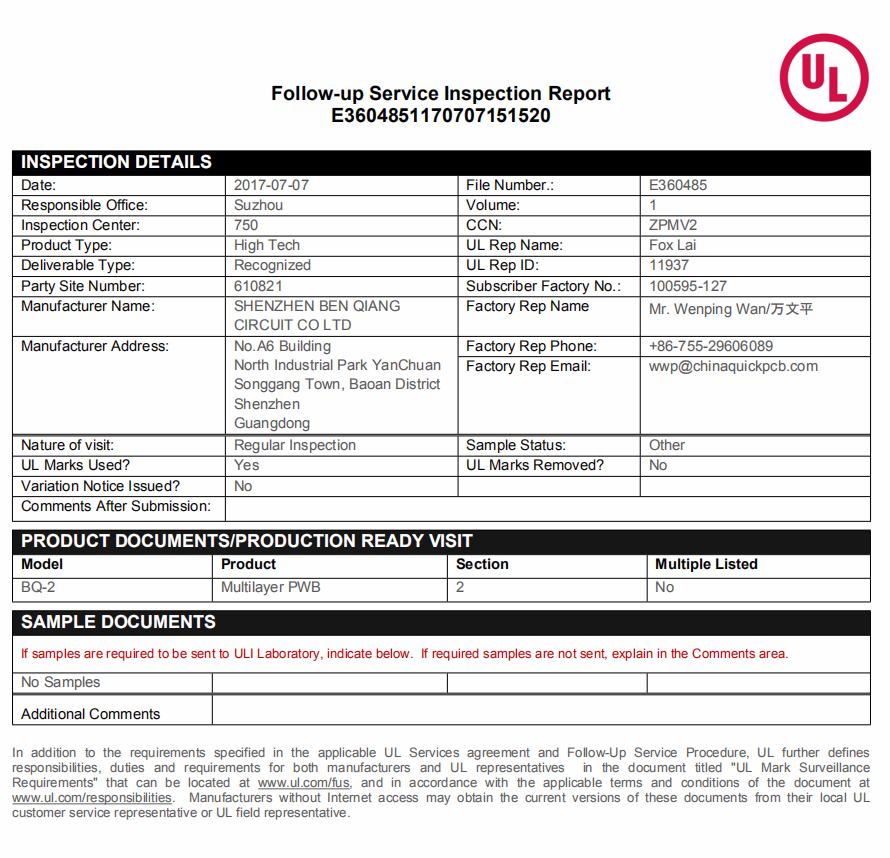

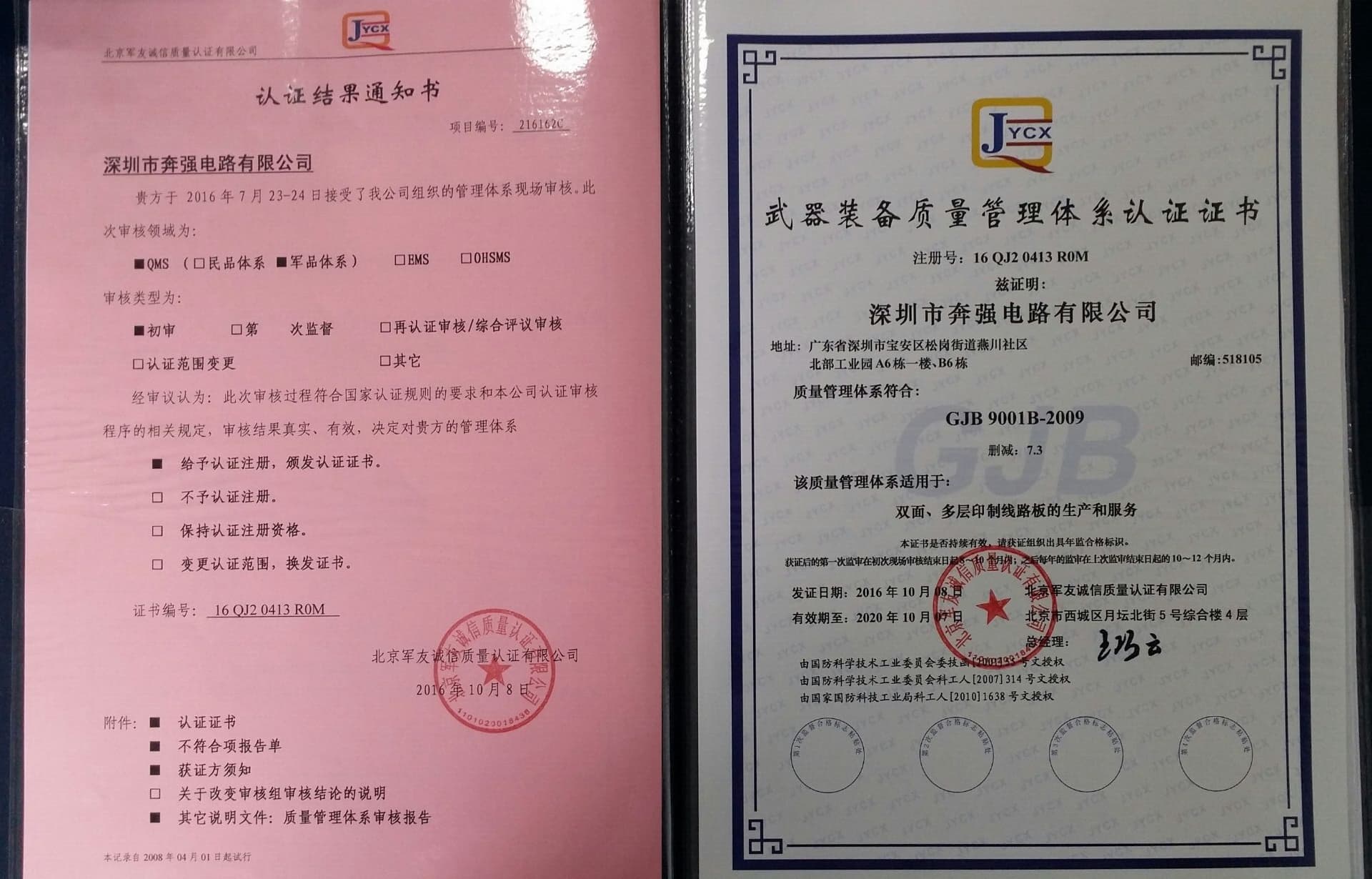

Our products are widely used in such realms as communication, industrial control, computer application, aviation, military projects, medical treatment, and test instruments. Core competitiveness: leading process and technology, high quality, high accurate delivery, urgent delivery, advisory service for customers, and optimal cost performance. Have obtained such certifications as ISO9001, ISO14001, TS16949, GJB9001A, UL (E360485) and RoHS.

We aim at establishing the most efficient, the most powerful quick manufacturing platform in the PCB sample plate as well as multiple medium and small batch field and at providing numerous scientific and technological innovation enterprises (including small and micro businesses) with the quick design and mass production-based service for modern electronic products. We also strive for setting up an open technical service platform and a senior team of PCB technical advisers and having the ability in offering total solutions for universal core technology in the electronic hardware design realm. On the strength of our ability in offering auxiliary multiple quick surface mounting services, we shall endeavor to provide customers with personalized one-stop hardware outsourcing service.

In the PCB manufacturing field, Benqiang has been maintaining efficient and prompt delivery of various products with the aim of supplying the most competitive PCB sample plates of China and establishing the manufacturing plant of small and medium batch. Besides, in combination with our high-quality excellent production management, our development and manufacturing ability and our PCB core technologies developed through constant effort and other advantages, we aim at helping Chinese enterprises with independent intellectual property right to speed up technological innovation and development continuously.

Detailed reference information

Prevailing product standard | IPC-A-600H (acceptance condition for printed plates) |

First pass yield and online reject ratio of our products | First pass yield 95% | reject ratio 2000PPM |

Test items of reliability experiment | Thermal shock test, clad layer and solder resisting adhesive force, solder resisting hardness, solder resisting and solvent resistance, solderability, warpage, thickness of cladding material and coating (including cooper thickness, thickness of lead and tin, thickness of nickel, solder resisting), slicing experiment, stripping strength of wire, thickness of nickel coating |

Development and design process | As our company carries out processing and production as per the documents and materials supplied by clients, the quality system does not include "design and development". |

Delivery capacity | Home delivery service, S. F. Express, DHL, UPS, FEDEX and other modes of express delivery; Full-time order managerial staff shall be in charge of following up the order and feedback. |

Provide prompt supply as well as process and emergency measures of goods not arrived; | The business order shall be handled within two hours and the engineering shall be handled within 8 hours. |

Training | Induction training, qualification training, on-the-job training, and the training in the annual training plan and training related to foreign affairs |

Service commitment | • Quick response within two hours; |

Quality policy | Meticulous production, strict control; |

Quality objective | Customer satisfaction >95% |

Quality objective | Customer satisfaction >95% |

Corporate spirit | Masculine aggressive, strong integrity and courage |

If you have any inquries, pls contact me at any time:

Lucy Zhang

Account Manger / Oversea Sales Department

Add: Building B6, Yanchuan Industrial Park, Songgang

Town,518127 Baoan District, Shenzhen, China.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LVTAODONG

- Address

- Building A5, Yanchuan Beibu Industrial Park, Songgang Town Shenzhen 518000 CHINA

- Product Category

- Other Passive Components,PCB & PCBA,Passive Components

- Year Established

- 2005

- No. of Total Employees

- 101-500

- Company introduction

-

Shenzhen Benqiang Circuit Co., Ltd. is a high-tech enterprise founded in 2005 in Shenzhen and engages in providing the most excellent and prompt service for the continuous innovation of scientific enterprises and in becoming a first-rate Chinese supplier of hardware outsourcing design service. Our PCB R&D manufacturing base is located in Shenzhen and Huizhou. Besides, we have a workshop of 80,000 square meters and more than 500 employees, 35% of whom are professional technical personnel and roughly 20% of whom have bachelor's and master's degree. So for we have set up branch offices in Beijing, Shanghai, Wuxi, Hangzhou, Wuhan, etc. and more than ten customer service centers. All these allow us to have put into place a marketing and technical service network which facilitates offering excellent and efficient service to more than 5,000 customers across the world.

Our products are widely used in such realms as communication, industrial control, computer application, aviation, military projects, medical treatment, and test instruments. Core competitiveness: leading process and technology, high quality, high accurate delivery, urgent delivery, advisory service for customers, and optimal cost performance. Have obtained such certifications as ISO9001, ISO14001, TS16949, GJB9001A, UL (E360485) and RoHS.

We aim at establishing the most efficient, the most powerful quick manufacturing platform in the PCB sample plate as well as multiple medium and small batch field and at providing numerous scientific and technological innovation enterprises (including small and micro businesses) with the quick design and mass production-based service for modern electronic products. We also strive for setting up an open technical service platform and a senior team of PCB technical advisers and having the ability in offering total solutions for universal core technology in the electronic hardware design realm. On the strength of our ability in offering auxiliary multiple quick surface mounting services, we shall endeavor to provide customers with personalized one-stop hardware outsourcing service.

In the PCB manufacturing field, Benqiang has been maintaining efficient and prompt delivery of various products with the aim of supplying the most competitive PCB sample plates of China and establishing the manufacturing plant of small and medium batch. Besides, in combination with our high-quality excellent production management, our development and manufacturing ability and our PCB core technologies developed through constant effort and other advantages, we aim at helping Chinese enterprises with independent intellectual property right to speed up technological innovation and development continuously.

Detailed reference information

Prevailing product standard

IPC-A-600H (acceptance condition for printed plates)

GJB 362A-96 (generic specification for flex-rigid printed plates)

GB/T16261-1996 (generic specification for printed plates)

GB/T2036-94 (terminology for printed circuit)

GB/T45488.4-1996 (segmentation specification for multilayer printed plates)

SJ/T10389-93 (packing, shipping and keeping of printed plates)

SJ/T10329-92 (rework, repair, and modification of printed plates)First pass yield and online reject ratio of our products

First pass yield 95% | reject ratio 2000PPM

Test items of reliability experiment

Thermal shock test, clad layer and solder resisting adhesive force, solder resisting hardness, solder resisting and solvent resistance, solderability, warpage, thickness of cladding material and coating (including cooper thickness, thickness of lead and tin, thickness of nickel, solder resisting), slicing experiment, stripping strength of wire, thickness of nickel coating

External parts as per customers' requirements:adhesive strength, fire resistance and insulation resistance .Development and design process

As our company carries out processing and production as per the documents and materials supplied by clients, the quality system does not include "design and development".

Delivery capacity

Home delivery service, S. F. Express, DHL, UPS, FEDEX and other modes of express delivery; Full-time order managerial staff shall be in charge of following up the order and feedback.

Provide prompt supply as well as process and emergency measures of goods not arrived;

The business order shall be handled within two hours and the engineering shall be handled within 8 hours.

Training

Induction training, qualification training, on-the-job training, and the training in the annual training plan and training related to foreign affairs

Service commitment

• Quick response within two hours;

• Standard communication in Chinese and English;

• CAMDocuments can be handled by the CAM Department within 24 hours;

• Highly experienced technical engineer;

• Express delivery no greater than 1m2 can be delivered within one to three days;

• Express delivery in small quantities (5m²) can be delivered within three to seven days;

• Express delivery in medium quantities (5-20m²) can be delivered within 7 to 10 days;

• The monthly delivery capacity is up to 8,000 varieties and in an area of 50,000 square meters;

• Before production, DPM inspection can be conducted through preliminary inspection on project and suggestion on product optimization will be made with specific purpose;

• The product and production have passed the authentication of DNV authoritative institution and re-inspection shall be conducted regularly;

• Electric performance test and AOI test shall be conducted on all the products;

• High voltage test, thermal shock test, reliability testing and insulation resistance can be carried out.

Various reliability tests to ensure intrinsic quality of products

• Home delivery service by professional Express and local service personnel;

• The delivery time is highly reliable in order to stably support the customers' development process and market delivery and to assist the customers in seizing the market.Quality policy

Meticulous production, strict control;

Quality-focused speed; supply highly reliable products;

Constantly improve and upgrade quality, technical and service level to meet the growing demands of customers;Quality objective

Civil productsCustomer satisfaction >95%

Comprehensive percent of pass>95%

Accurate delivery rate>95%

Complaint rate <1.0%Quality objective

Military productsCustomer satisfaction >95%

Comprehensive percent of pass>95%

Accurate delivery rate>95%

Complaint rate <0.5%Corporate spirit

Masculine aggressive, strong integrity and courage

If you have any inquries, pls contact me at any time:

Lucy Zhang

Account Manger / Oversea Sales Department

Add: Building B6, Yanchuan Industrial Park, Songgang

Town,518127 Baoan District, Shenzhen, China.

Website: http://www.chinaquickpcb.com

E-mail/Skype: lucy@chinaquickpcb.com

Phone/Wechat/Whatsapp:+86 15071376509

- Factory Information

-

Shenzhen Benqiang Circuit Co., Ltd

- Main Product

Related Products

Testing, Measuring Equipment, Test Bench

dc contactor

LAN Transformer 10/100/1000 Base

ICAR Electrolyte Capacitors 0.22µF +2x2200pF

PCB, PCBA, Rigid Flex PCB, FPCB, Multi Layer PCB, PWB

China

China