Metal waste recycling machine briquette press

Metal waste recycling machine briquette press

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Anyang Forging Press

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Available,OBM,ODM,OEM

- Shipping / Lead Time

- 3 Month / 2 Day

- Category

- Other Metal & Metallurgy Machinery

Anyang Forging Press Machinery Industry Co., Ltd

- Membership

- PRO

- Recent Visit

- Dec 28, 2024

- Country / Year Established

-

China

/

1956

China

/

1956

- Business type

- Manufacturer

- Verified Certificate

-

8

| Product name | Metal waste recycling machine briquette press | Certification | - |

|---|---|---|---|

| Category | Other Metal & Metallurgy Machinery | Material | - |

| Keyword | recycling machine , scrap metal , briquette press , metal briquette press | Unit Size | 1.0 * 1.0 * 1.0 mm |

| Brand name | Anyang Forging Press | Unit Weigh | 1 mg |

| origin | China | Stock | 5 |

| Supply type | Available,OBM,ODM,OEM | HS code | - |

Product Information

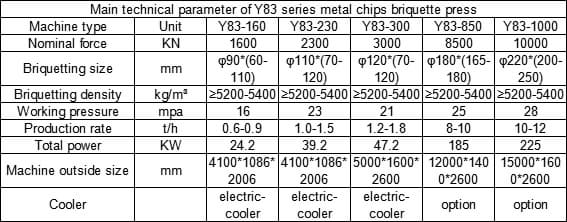

Introduction of Y83 Metal Chips Briquette Press

Y83 series briquette press are widely being used for machining company, smelting plant, foundry plant, metal scrap recycling and processing plant which has metal chips, which are designed for compacting the cast iron chips, steel chips, aluminum chips, copper brass chips etc metal chips into high density blocks.

Y83 series Metal Chips Briquette Line widely being used for large machining company, smelting plant, foundry plant, metal scrap recycling and processing plant which has large quantity of metal chips, this briquette line designed for compacting the cast iron chips, steel chips, aluminum chips, copper brass chips etc metal into high density blocks, directly feeding furnace for smelting or casting, reduce production costs and reduce environment pollution.

This briquette line able to carrying out automatically shredding, feeding, briquette and briquettes charging out etc works, with features of strong capacity production, and high efficiency, lower labor intensity, suitable for large enterprise.

Technical features:

1. Don’t need to add any additives in the briquetting process.

2. The metal blocks can put into furnace for smelting or casting directly, reduce production costs and reduce environment pollution.

3. Electric part is controlled by PLC, the anti-interference is strong, automation is high and operation is simple.

4. Hydraulic station adopts the entirety-typed integration valve block and large diameter cartridge inserted valve, avoids the oil leakage, lowers the oil temperature of system, and enhances the stability of system.

5. Frame adopts the entirely casting steel products, avoids the cranking of steel plate welding assembly, and enhances the stability of machine and lengthens the longevity.

6. Oil cylinder adopts the tandem type cylinders, enhances the velocity of movement and production efficiency.

7. Conveyor and feeder are for option, which will lower the labor intensity greatly.

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Land Transportation,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | 3 Month |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | 2 Day |

- President

- Liu Wei

- Address

- West part of Changjiang road, No. 26, Anyang, Henan, China, West part of Changjiang road, No. 26, Anyang, Henan, China

- Product Category

- Metal Forging Machinery

- Year Established

- 1956

- No. of Total Employees

- 501-1000

- Company introduction

-

Anyang Forging Press (Group) Machinery Industry Co., Ltd is the biggest forging hammer manufacturer in China, Our company has 60 years history in Producing forging hammer. Our company has been identified as the national high-tech company. We drafted the national standard for CNC fully hydraulic die forging hammer, Electric hydraulic forging hammer, Pneumatic forging hammer. Our company is one of the high-tech and high-growth enterprise in Henan Province. We are the executive director of China Forging Association and the Vice President of Henan Forging Association.

Our company has passed ISO9001: 2008 quality certificate and our hammer have passed CE certification. Two products have been given the original certificate to protect the best quality machines.

Our company covers about 60 acres with four branch factories. Our company has the provincial level products designed research center and has sales center, after-sales center, quality control and management center, machining center and large heat treatment and product assembly center, which can provide the compete set of forging equipment.

Our products have been exported to USA, Germany, UK, France, Australia, India, Vietnam, Pakistan etc 60 countries and gain high reputation all over the world.

Our company follows the principle to service for the forging industry development for forging customers and pursuit the satisfaction of customer. We will offer the high-quality products and service to contribute our effort for the development of world forging industry.

Anyang Forging Press Numerical Control Equipment Co., Ltd

Add: West part of Changjiang road, Anyang City, Henan, China

Contact: Michael Duan

WhatsApp: +86-18625862110

Email: michael@chinesehammers.com

Website: http://www.chinesehammers.com

LinkedIn: https://www.linkedin.com/in/michael-duan/

Facebook: https://www.facebook.com/michael.duan.3998

Youtube: https://www.youtube.com/c/DuanMichaelAutomaticForgingMachine

- Main Markets

-

China

China

Egypt

Egypt

India

India

Turkey

Turkey

U. Kingdom

U. Kingdom

U.S.A

U.S.A

Ukraine

Ukraine

Ussr

Ussr

Vatican City

Vatican City

Yugoslavia

Yugoslavia

- Factory Information

-

Anyang Forging Press Company

- Main Product

Related Products

Portable Rebar Cutter

Date Pin (Date Core)

Portable line boring machine, Elsa Supercombinata EASY Compact

pipe and sheet metal cnc plasma cutter

Automatic precision metal cutting machine