Introduction of Magnesium Engine Cover & Forming System

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Vehicle Accessories

SAE CHANG

- Verified Certificate

-

7

| Product name | Introduction of Magnesium Engine Cover & Forming System | Certification | - |

|---|---|---|---|

| Category | Other Vehicle Accessories | Ingredients | - |

| Keyword | automobile parts , induction , magnesium engine room cover , engine room cover | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

SAE CHANG Co., Ltd. has specialized in manufacturing snapring and fastener, sorts of mechanical parts, with the use of carbon steel. These days, the company has been developing and commercializing mechanical parts not only in the industrial machinery area, but in the automobile area. By performing the creative and continuous R&D, all executives and employees of SAE CHANG Co., Ltd. will do the best to grow to a global company with competitive technology, quality, and productivity in the rapidly changing and infinite competition era.

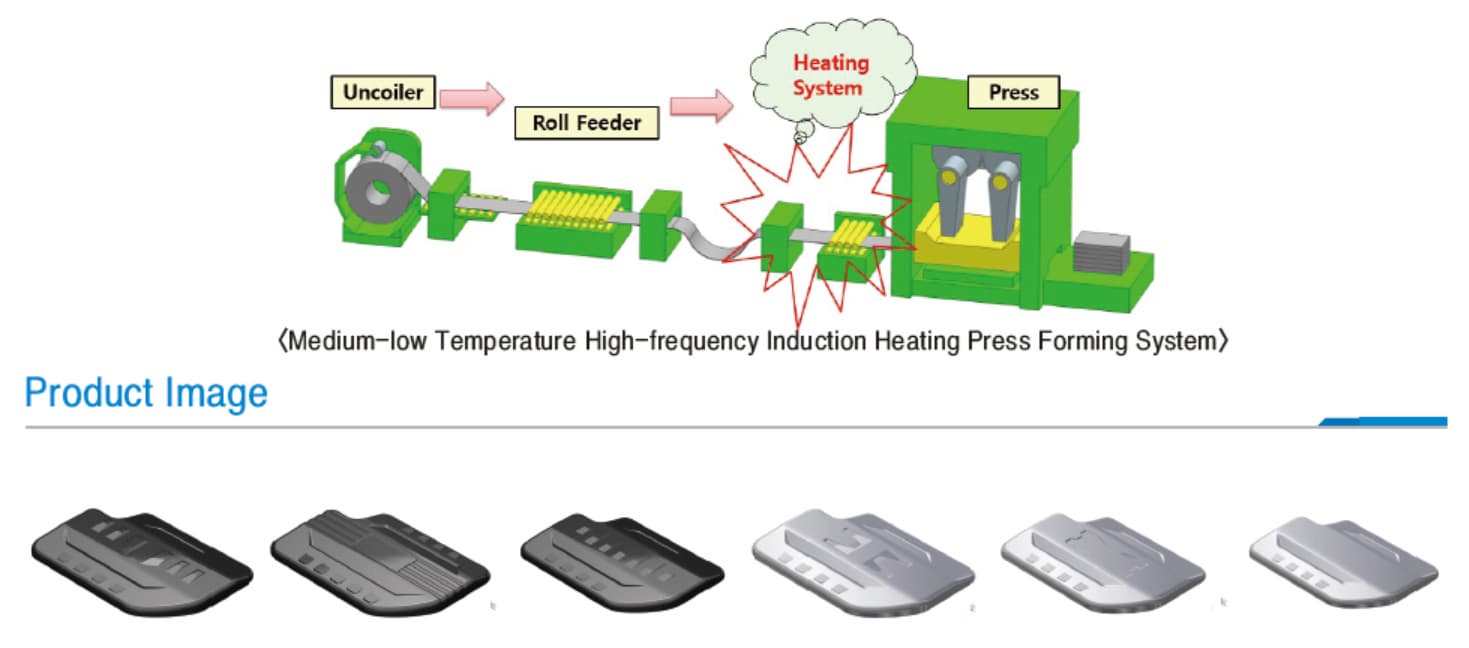

Specific project : Engine room cover design Developed thermo-diffused engine cover molding system using low-temperature high-frequency induction heating press with surface treatment

Product application : Introduction of Magnesium Engine Cover & Forming System

Development content : The material applied with medium-low temperature high-frequency induction heating method is heated to apply 100~150℃ mold for manufacturing the magne

-sium engine cover. The system is basically composed of largely of 5 modules including the un-coiler, leveler feeder, high-frequency induction heating device, mold and press that are the peripheral equipment of the press, and additionally with a temperature measurement

device that can measure the temperature distribution of the magnesium plate.

PRODUCTION EQUIPMENTS

Equipment | CAPA | Quantity | Maker |

PRESS | 300TON | 1 | SIMPAC |

PRESS | 200TON | 2 | SIMPAC |

PRESS | 160TON | 1 | HWAIL |

PRESS | 110TON | 1 | KOMATSU |

PRESS | 80TON | 1 | SAMJIN |

PRESS | 60TON | 2 | HWAIL |

PRESS | 45TON | 2 | SHINOHARA |

ETC. PRESS | 40TON | 10 | SAMJIN |

TOTAL |

| 20 |

|

GENERAL PURPOSE EQUIPMENT

Equipment | Quantity | Maker |

Double Side Fine Grinding M/C | 1 | BUKUK PRECISION |

Bench Lathe | 3 | BUKUK PRECISION |

Roll Feeder | 9 | DONGMYUNG |

Uncoiler | 9 | DONGMYUNG |

BARREL | 10 | YOUNGIN |

Tempering Furnace | 1 | SUNGSIN |

Grinding M/C | 1 | MYUNG SUNG |

TOTAL | 34 |

|

MEASURING EQUIPMENTS

Equipment | SPE'C | Quantity |

3D MEASURING SYSTEM | MH20i | 1set |

VIDEO MEASURING SYSTEM | 250×150/0.001 | 1set |

SPRING TESTER | 200kgf | 1set |

VICKERS HARDNESS TESTER | - | 1set |

ROCKWELL HARDNESS TESTER | 150kgf | 1set |

PLATING THICKNESS ANALYZER | - | 1set |

ROUGHNESS TESTER | - | 1set |

MICROMETER | 0~25㎜ | 5set |

VERNIER CALIPERS | 0~150/200㎜ | 8set |

VERNIER CALIPERS | 0~300㎜ | 2set |

DIAL INDICATOR | 0.8(0.01)㎜ | 1set |

PIN GUAGE | 191PCS | 1set |

MAGNETIC V-BLOCK | KMV800 | 2set |

GAUGE BLOCK SET | 1~25㎜(10PCS) 12.0±0.1(1PCS) | 1set |

HEIGHT GUAGE | 0~300㎜ | 3set |

PRODUCTION PROCESS

ENTERING RAW METAL (SK5/S50C/S60C, SPCC/SPHC) |

↓ |

PRESS LINE(COMPOUND, PROGRESSIVE) |

↓ |

HEAT TREATMENT LINE(QT, AUSTEMPER) |

↓ |

BARREL GRINDING LINE |

↓ |

SURFACE TREATMENT (ALKALI BLACK OXIDE, PHOSPHATE COATING, ZINC PLATING, ELECTRIC NICKEL ELECTROCOATING, DACRO) |

↓ |

INSPECTION & PACKING |

↓ |

STACK PACKING |

↓ |

PRODUCT |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Ryu Ki-ryong

- Address

- 68-8 Seongseogongdan-ro 51-gil Dalseo-gu Daegu, Dalseo-gu, Daegu, Korea

- Product Category

- Other Vehicle Equipment

- Year Established

- 1987

- Company introduction

-

Since its foundation in 1987, SAE CHANG Co., Ltd. has specialized in manufacturing snapring and fastener, sorts of mechanical parts, with the use of carbon steel. These days, the company has been developing and commercializing mechanical parts not only in the industrial machinery area, but in the automobile area. By performing the creative and continuous R&D, all executives and employees of SAE CHANG Co., Ltd. will do the best to grow to a global company with competitive technology, quality, and productivity in the rapidly changing and infinite competition era. We promise to become a reliable company to meet customer needs at any time and any place. Ryu Ki-ryong, CEO of SAE CHANG CO., LTD.

- Main Markets

-

U.S.A

U.S.A

- Main Product

Related Products

Engine Mount Rubber Hose

Spare Parts for Ssangyong Cars

KBC Bearing

Heater Core : Korean Auto Spare Parts : CARNIX

Korean Car Accessories

South Korea

South Korea