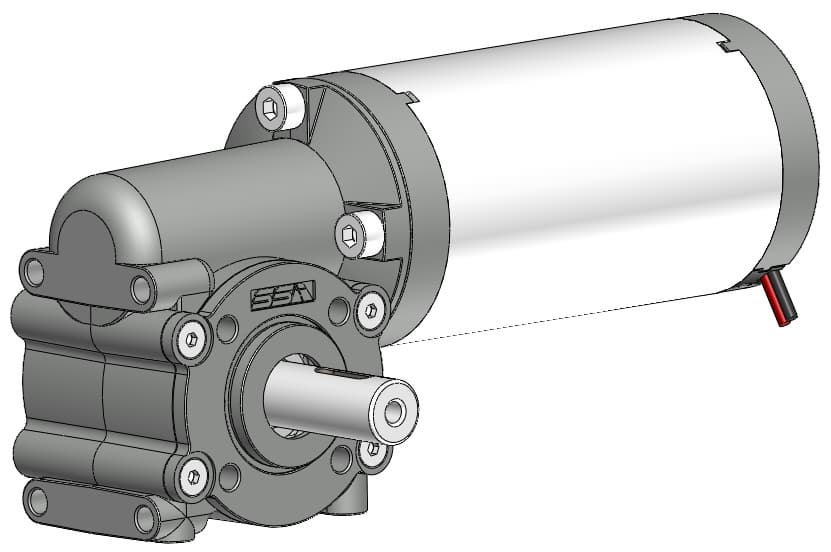

DC Worm Geared Motor 25W For Automatic Sliding Door

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- SSA motor

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Automatic Door Operators , Motor Accessories

SSA MOTOR (SungShin Automation Ltd)

- Verified Certificate

-

17

| Product name | DC Worm Geared Motor 25W For Automatic Sliding Door | Certification | - |

|---|---|---|---|

| Category |

Automatic Door Operators

Motor Accessories |

Ingredients | - |

| Keyword | automatic sliding door , dc motor , motor parts , worm geared dc motor | Unit Size | - |

| Brand name | SSA motor | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8501101000 |

Product Information

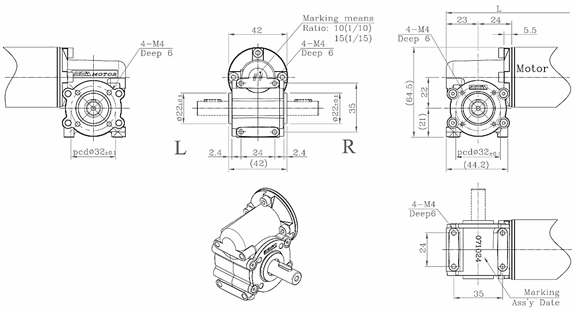

SD 42 Series

AutoDoor, Medical device, ETC.

■ Low-Cogging and high power

■ Built-in Noise Filter

■ Insulation level B

■ Protection class IP50, higher class available on request.

■ the standard version has leads(500mm)

■ Motor shaft held by Ball bearing

■ Motor, voltage, shaft spec and lead wire, etc. are changeable on customers request

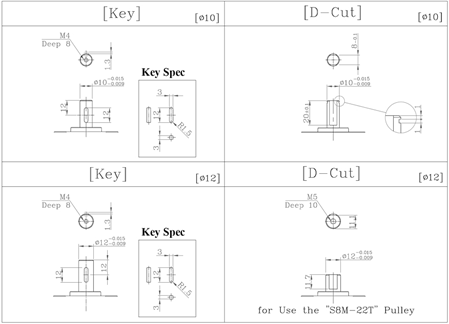

■ Specification (Worm Gear Head)

DATA / SPEC | SW42 Series | |||||

Reduction Ratio | Module | M1 | M0.7 | |||

Ratio & Threads | 1/10 [3’rd] | 1/15 [2’rd] | 1/30 [1’rd] | 1/25 [2’rd] | 1/50 [1’rd] | |

Efficiency | [%] | 70 | 65 | 55 | 60 | 50 |

Continuous Load | [Kgf.cm] | 50 | 40 | |||

Axial Load | [Kgf.cm] | 150 | 100 | |||

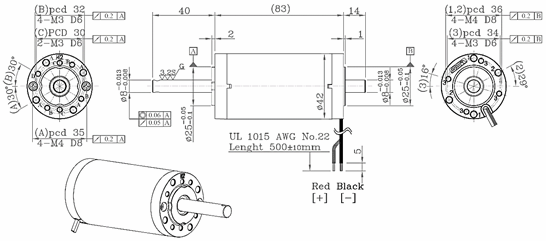

■ Specification (Motor only)

DATA / SPEC | SD42 | |

Model | 2524-43 | |

Output | W | 25 |

Rated Voltage | VDC | 24 |

Rated Speed | rpm | 3500 |

Rated Torque | Kgf.cm | 0.8 |

Rated Current | A(Max) | 2.0 |

Stall Torque | Kgf.cm(Min) | 3.8 |

Stall Current | A | 7.3 |

No Load Speed | rpm | 4300 |

No Load Current | A(Max) | 0.8 |

Cogging Torque | gf.cm | 300 |

Run Duty | Hours | 3000 |

- The data wrote according to the No Load 4300rpm

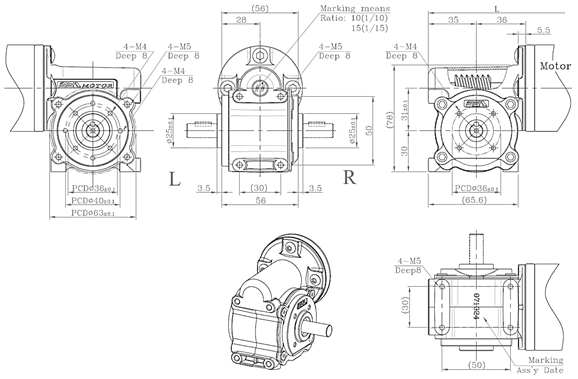

■ Specification (Worm Gear Head)

DATA / SPEC | SW63 Series | |||||

Reduction Ratio | Module | M1.5 | M1.0 | |||

Ratio & Threads | 1/10 [3’rd] | 1/15 [2’rd] | 1/30 [1’rd] | 1/24 [2’rd] | 1/48 [1’rd] | |

Efficiency | [%] | 70 | 65 | 55 | 60 | 50 |

Continuous Load | [Kgf.cm] | 80 | 60 | |||

Axial Load | [Kgf.cm] | 300 | 200 | |||

■ Specification (with SD63X90W DC Motor)

Motor Type & Speed (Lengths “L”) | Output [W] | Voltage [VDC] | Ratio [SW63] | No Load | at Rated Load | Stall | Cogging Torque [Kgf.cm] | ||||

Speed [r/min] | Current [A] | Speed [r/min] | Current [A] | Torque [Kgf.cm] | Current [A] | Torque [Kgf.cm] | |||||

SD63X90 3700rpm

(209mm) | 90 |

| 10 | 370 | 1.3 | 316 | 5.1 | 19.3 | 34.1 | 127 | 8.0 |

15 | 246 | 1.3 | 210 | 5.1 | 27.0 | 34.1 | 178 | 10.0 | |||

24 | 154 | 1.3 | 131 | 5.1 | 39.8 | 34.1 | 200 | 10.0 | |||

30 | 123 | 1.3 | 105 | 5.1 | 45.7 | 34.1 | 300 | - | |||

48 | 77 | 1.3 | 65 | 5.1 | 66.4 | 34.1 | 200 | - | |||

40 | 10 | 370 | 0.8 | 317 | 2.9 | 19.1 | 20.4 | 127 | 8.0 | ||

15 | 246 | 0.8 | 211 | 2.9 | 26.8 | 20.4 | 178 | 10.0 | |||

24 | 154 | 0.8 | 132 | 2.9 | 39.7 | 20.4 | 200 | 10.0 | |||

30 | 123 | 0.8 | 105 | 2.9 | 45.6 | 20.4 | 300 | - | |||

48 | 77 | 0.8 | 66 | 2.9 | 66.2 | 20.4 | 200 | - | |||

90 | 10 | 370 | 0.3 | 318 | 1.5 | 19.0 | 8.5 | 127 | 8.0 | ||

15 | 246 | 0.3 | 212 | 1.5 | 26.7 | 8.5 | 178 | 10.0 | |||

24 | 154 | 0.3 | 132 | 1.5 | 39.5 | 8.5 | 200 | 10.0 | |||

30 | 123 | 0.3 | 106 | 1.5 | 45.4 | 8.5 | 300 | - | |||

48 | 77 | 0.3 | 66 | 1.5 | 66.0 | 8.5 | 200 | - | |||

SD63X90 3100pm

(209mm) | 90 |

| 10 | 310 | 1.3 | 240 | 5.1 | 23.0 | 32.8 | 127 | 8.0 |

15 | 206 | 1.3 | 160 | 5.1 | 32.0 | 32.8 | 178 | 10.0 | |||

24 | 129 | 1.3 | 100 | 5.1 | 47.3 | 32.8 | 200 | 10.0 | |||

30 | 103 | 1.3 | 80 | 5.1 | 54.2 | 32.8 | 300 | - | |||

48 | 64 | 1.3 | 50 | 5.1 | 78.9 | 32.8 | 200 | - | |||

40 | 10 | 310 | 0.8 | 243 | 2.9 | 22.6 | 19.5 | 127 | 8.0 | ||

15 | 206 | 0.8 | 162 | 2.9 | 31.9 | 19.5 | 178 | 10.0 | |||

24 | 129 | 0.8 | 101 | 2.9 | 46.8 | 19.5 | 200 | 10.0 | |||

30 | 103 | 0.8 | 81 | 2.9 | 54.0 | 19.5 | 300 | - | |||

48 | 64 | 0.8 | 50 | 2.9 | 78.1 | 19.5 | 200 | - | |||

90 | 10 | 310 | 0.3 | 247 | 1.5 | 22.4 | 8.2 | 127 | 8.0 | ||

15 | 206 | 0.3 | 165 | 1.5 | 31.6 | 8.2 | 178 | 10.0 | |||

24 | 129 | 0.3 | 103 | 1.5 | 46.5 | 8.2 | 200 | 10.0 | |||

30 | 103 | 0.3 | 82 | 1.5 | 54.5 | 8.2 | 300 | - | |||

48 | 64 | 0.3 | 51 | 1.5 | 77.5 | 8.2 | 200 | - | |||

- When you place an order more than 1LOT/100ea, It is possible to produce by special type.

- Our standard Spindle is made by non-heat treatment. But, if you would like to get the Spindle made heat treatment, it can be made as your request.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lee Ki Soung

- Address

- 1120 sambo techno tower jomaruro 385beon-gil 122, Bucheon-si, Gyeonggi-do, Korea

- Product Category

- Motor Accessories

- Year Established

- 1998

- No. of Total Employees

- 1-50

- Company introduction

-

Sungshin Automation recognizes production materials of the highest quality, best overall motor performance, operational efficiency of the motors comprehensive technical assistance & support for our customers and strives to meet it always.

We are sincerely appreciated your visiting our Website.

As one specialized circulation and manufacturer, we have been doing our best for customer's convenience and improvement.

We have been trying to improve competitive power and quality through the highest quality and the most effective cost.

Our desire is not only to exceed our customer's motor needs operationally, but meet their service and upkeep requirements moreover we are proud of being equipped with the most technologically advanced facilities for production, most informed and skilled engineers, which all makes it possible to guarantee our customers with the best motor products.

The heart of every mechanism, in electrical eared motor is the dependability of its performance-we recognize production materials of the highest quality, best overall motor performance, operational efficiency of the motors, comprehensive technical assistance & support for our customers and strives to meet it always.

The collaborative technical knowledge and working experiences of our manufacturing team, has given us a stronger understanding of what is required for a successful partnership to create innovative design, perform superior testing, process mass production and offer best-in class servicing for all our customers.

We express our sincere hope for prosperity in our customer's business and we look forward to working with you and your motor requirements.

- Main Markets

-

Australia

Australia

Turkey

Turkey

U.S.A

U.S.A

- Main Product

South Korea

South Korea