Vitrified diamond grinding wheels for Precision Grinding of

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Moresuperhard

- Payment Terms

- Others,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- diamond grinding wheels, vitrified diamond, vitrified diamond wheels, for precision grinding

- Category

- Abrasive Tools

Henan More Super Hard Products Co.,Ltd

- Verified Certificate

-

7

| Product name | Vitrified diamond grinding wheels for Precision Grinding of | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | diamond grinding wheels , vitrified diamond , vitrified diamond wheels , for precision grinding | Unit Size | - |

| Brand name | Moresuperhard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

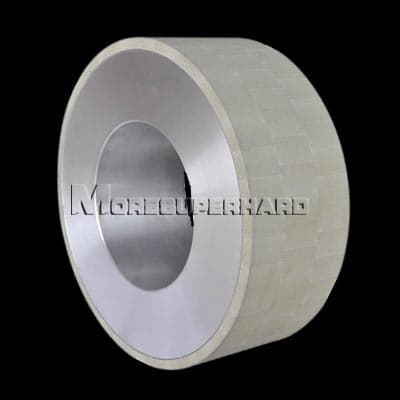

Brief Introduction: Vitrified diamond wheels are used for rough and precision grinding the Cylinder of Polycrystalline Diamond Compacts (PDC cutter).

Type: 1A1, 6A1, 9A1

Application: rough and precision PDC cutter

Details

Description of the vitrified diamond grinding wheel:

Vitrified products have the features of sharp cutting, high efficiency, long life ,easy dressing. Vitrified diamond wheels are used for rough and precision grinding the Cylinder of Polycrystalline Diamond Compacts (PDC cutter).

Application of vitrified diamond grinding wheels for PDC :

Grinding PCD, PCBN,tungsten carbide, ceramic, cermet, etc.

Advantages of vitrified diamond grinding wheels for PDC :

* Compared with resin diamond grinding wheel, vitrified bond wheels lead to 35% grinding cost reduced, 40% grinding time of each PDC saved, and the size precision of PDC improved (from ±0.03mm to ±0.01mm)

* Good surface finish after grinding and high efficiency

* Less dressing time, long service life and stable quality

Feature/Benefit of the vitrified diamond grinding wheel:

1. Very Good Abrasion Resistance

2. Good Form-holding capability

3. Least Resistance to Damage

4. Chemical Stability

5. Controllable Stock Removal Rate and Surface Finish Characteristics

6. Heat Resistance

Specifications of vitrified diamond wheels for rough and precision grinding PDC:

rough grinding PDC cutter

Model | D (mm) | T (mm) | H (mm) | X (mm) |

1A1 | 200 | 50 | 75 | 10 |

250 | 50 | 75 | 10 | |

300 | 50 | 127 | 10 | |

350 | 50 | 127 | 10 | |

400 | 50 | 203 | 10 | |

450 | 50 | 228.6 | 10 | |

500 | 50 | 305 | 10 | |

| ||||

Precision grinding PDC cutter

Model | D (mm) | T (mm) | H (mm) | X (mm) |

1A1, 6A1, 9A1 | 200 | 50 | 75 | 10 |

250 | 100 | 75 | 10 | |

300 | 100,150 | 127 | 10 | |

350 | 125, 150 | 127 | 10 | |

400 | 150,300 | 203 | 10 | |

450 | 150,200,300 | 228.6 | 10 | |

500 | 150,200 | 305 | 10 | |

| ||||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- B906,Wanda Plaza, Zhongyuan Road, Zhengzhou, Henan, China

- Product Category

- Other Machinery Parts

- Year Established

- 2014

- Company introduction

-

"Henan More Super Hard Products Co.,Ltd" is specialized in manufacturing and marketing of diamond & CBN tools.

- Main Product

Related Products

_2.png)

Xonite Dendroid Brush(cleaning)

Sun Turbo Cutter

Convex Polishing Pad for curved counter tops

Diamond Wheels for Walter Grinding Machine

Pentagon Cup Grinding Wheel

China

China