Forged Entire CNC Machined Francis Runner

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Getai

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other General Industrial Equipment

Shenyang Getai Hydropower Equipment Co.,Ltd

- Verified Certificate

-

7

| Product name | Forged Entire CNC Machined Francis Runner | Certification | - |

|---|---|---|---|

| Category | Other General Industrial Equipment | Ingredients | - |

| Keyword | francis turbine , pelton turbine , kaplan &tubular turbine | Unit Size | - |

| Brand name | Getai | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Forging could considerably improve metal’s organizational structure and mechanical property.

Forging offers uniformity of composition and structure. Forging results in metallurgical recrystalisation and grain refinement as a result of the thermal cycle and deformation process. This strengthens the resulting steel product particularly in terms of impact and shear strength.

Forged steel is generally stronger and more reliable than castings of same material due to the fact that the grain flows of the steel are altered, conforming to the shape of the part.

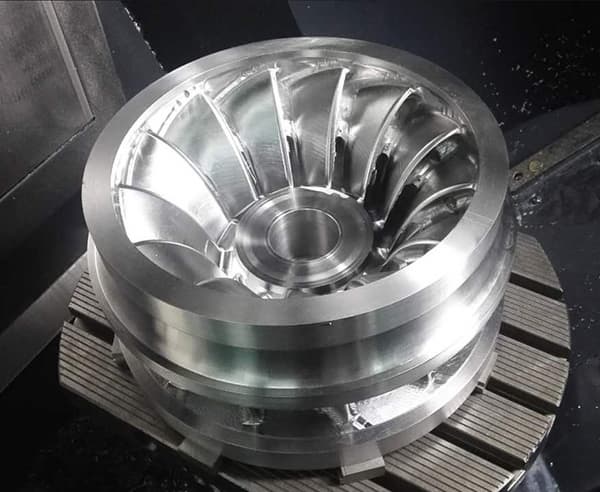

Forged Integrally +100% CNC Machining Francis Turbine Runner

1. GETAI has improved the manufacturing procedure of Francis turbine runner which suffered from the problems such as the cavitation and abrasion, welding seam cracks between crown, band and vanes, block worn off from vane etc. The whole Francis runner is forged integrally followed by entire CNC machining to eliminate tiny blowholes and slag inclusions existed on passage surface which accelerate cavitation and abrasion, and solve the potential risk existed by unreleased stress left after welding. The Francis turbine runner service life prolonged consequently.

In the case the high head Francis runner with long and narrow passageway which is hard for entire CNC machining or the runner size exceeds the forging range which can not be forged integrally, GETAI applied a procedure by dividing the runner to two parts which consisted of crown with half vanes and band with rest half, both two parts can be forged integrally with entire CNC machining and welding assembled in final. The welding applied to the middle of vane, where is convenient for single pass welding without touch of potential crack area, the operation security and service life are improved largely.

Samples exhibited below is for forged integrally+100% CNC machined Francis turbine runner (half part) which finished by our five axis linkage CNC machine.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Sun Tianrong

- Address

- No.205,HongHui Road,Yuhong District,Shenyang,Liaoning,China

- Product Category

- Other General Industrial Equipment

- Year Established

- 1992

- No. of Total Employees

- 101-500

- Company introduction

-

<p>

SHENYANG GETAI HYDROPOWER EQUIPMENT CO., LTD. is located in Shenyang City, the old Northeastern industrial base of China. GETAI is a high technology enterprise established in 1992, aiming to supply integral solution for new and old hydropower plants. Its main products include high efficient Pelton turbine, Francis turbine, Kaplan turbine and relevant accessories.

Shenyang Getai Hydropower Equipment Co.,Ltd main products: Pelton Turbine, Francis Turbine, Kaplan/Tubular Turbine, Pelton Turbine Generator, Francis Turbine Generator, Double Francis Turbine, Pelton Turbine Formula, welcome to our factory!

Our company covers an area of 30,000 square meters, employs more than 140 people, more than 20 professionals and technical personnel, we has formed a unique technological advantage in R&D, design and manufacturing, We provide pelton turbine experiment, francis turbine diagram, francis turbine working and so on. We established an overseas technology research and development center in Canada in 2015. Through the use of CFD computer dynamic water flow simulation system, it could comprehensively analyzes and calculates the technical parameters of the newly-built power station and the actual operation status of the upgraded power station, providing users with customized design to maximizing the generation capacity of the power station. Turbine core components are subjected to force analysis using finite element FEA technology, and weak links are reasonably strengthened. Castings are manufactured using AOD, VOD ultra-low carbon refined molten steel, and the service life is extended on the basis of ensuring the safe use of the product.

We have dozens of high precision lathe,including φ8m, φ6.3m, φ2.5m, M4000H2, GMB2540, TK6920, TK6516, TK6513 and multi-axis CNC boring and milling machining centers. Getai manufactured the first entirely CNC machined forged Pelton runner as well as entirely CNC machined forged Francis runner in China.

Getai Hydropower has provided advanced design and renovation solutions for many new and old hydropower stations at home and abroad. The products are distributed to more than 30 provinces, cities, autonomous regions and more than 20 countries abroad. We advocate green production, people-oriented, and honest management. On the basis of several years of turbine manufacturing experience and excellent technology with continious upgrading, GETAI will offer the best products and service to each customer.

- Main Product

Related Products

A-FRAME

K2UV SERIES UV MARKING LASER MACHINE

SUBMERSIBLE PUMP

15HP concrete floor grinding and polishing machine

Antistatic Earthing Touch Pad / Discharge electrostic Pad

China

China