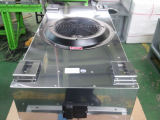

ZYD-W Fully Enclosed Double-stage Vacuum Insulating Oil Trea

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- FUOOTECH

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Water Softeners , Cleaning Equipment & Parts

FuooTech Oil Filtration Group

- Verified Certificate

-

8

| Product name | ZYD-W Fully Enclosed Double-stage Vacuum Insulating Oil Trea | Certification | - |

|---|---|---|---|

| Category |

Water Softeners

Cleaning Equipment & Parts |

Ingredients | - |

| Keyword | oil purifier , lubricating oil purifier , fire-resistant oil purifier | Unit Size | 800.0 * 1200.0 * 1000.0 mm |

| Brand name | FUOOTECH | Unit Weigh | 250 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Kevin Chang

- Address

- No. 5 Hongshi Street, Jiulongpo District, Chongqing, China

- Product Category

- Electrical Equipment

- Year Established

- 1999

- No. of Total Employees

- 101-500

- Company introduction

-

FuooTech Oil Filtration Group is one of largest R&D based high-tech group engaged in designing, developing, manufacturing and exporting various vacuum oil/fluid purifiers, oil filtration system, oil regeneration machine, transformer evacuation system, dry air generator, electrical testing equipment and oil testing kits for various industries for more than 18 years, helping clients all over the world solve various oil problems.

Fuootech develops custom solutions for virtually any application involving industrial oil management. With FuooTech oil management systems, oils can be re-used indefinitely, thus drastically reducing new oil purchasing and waste oil disposal, protecting environment, and improving productivity for industries to be more competitive in the global economy.

Nowadays, the company's sales and service network covers all the provinces of China and exports to more than 118 countries. Our products are more and more popular in domestic market and international market based on High quality, advanced technology, competitive price and excellent before & after sales service, as well as continuouse technical supports.

FuooTech's oil filtration systems & oil testing kits are extensively used in the fields of electrial power, power station, power transmission, power generation, Petrochemical, petroleum, Paper and Pulp, compressor, mechanical manufacture, steel mills, electrical utilities, engineering contractors, metallurgy,railway, aviation etc. which are consuming various oils. More than 100 standard models are offered to different clients and also can be customerized according to actual need of oil solutions in different areas.

- Main Product

China

China