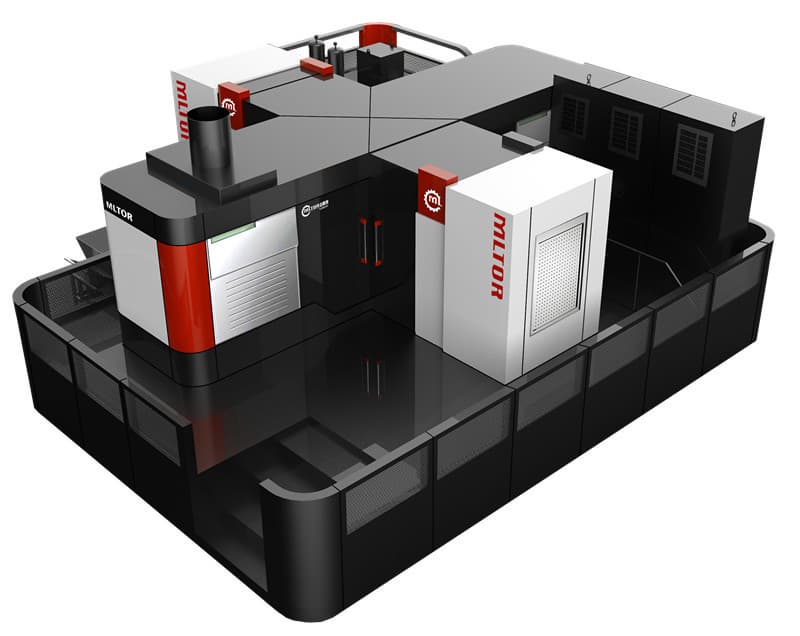

8-spindles and 10-axis Pellet Dies Gun Drilling Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MLTOR

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- gun drilling machine, pellet dies drilling machine, feeding ring die drilling machine, biomass ring die drilling

- Category

- Machinery Tools

Zhongshan Mltor Intelligent Equipment Co.,Ltd

- Verified Certificate

-

6

| Product name | 8-spindles and 10-axis Pellet Dies Gun Drilling Machine | Certification | - |

|---|---|---|---|

| Category | Machinery Tools | Ingredients | - |

| Keyword | gun drilling machine , pellet dies drilling machine , feeding ring die drilling machine , biomass ring die drilling | Unit Size | 7.0 * 7.0 * 2.9 m |

| Brand name | MLTOR | Unit Weigh | 27000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Key specifications/special features:

8-spindle & 10-axis of digital NC control ring die deep hole drilling machine for feeding and biomass pellet

This machine is made for feeding and biomass ring die drilling pellet mill or grinding machine which used on poultry, fish and other sea food, livestock and wood and straw biomass product

Equipment features:

- Classic flagship deep hole drilling machine among ring-die drilling machine

- 10-axises & 8-spindles with customized intelligent control system

- High efficiency: finish processing 8 holes high speed drilling in one time

- High precision: realize 8-spindle flexible control and precision spindle indexing.

- Innovated electric spindle with high speed up to 30000rpm, to achieve the same effect as drilling metal same like drilling mud.

- Intelligent NC control, machines is stable and reliable, unique processing technology experts library, with the broken drill bit protection function

- Humanized operation, easy to learn

- Preferred machine for ring-die manufacturers

- Ring-die dedicated drilling system (MLT-Z228i) is marked by Mltor itself, stable hardware and software system, user-friendly, intuitive interface, no programming, parameter of hole is input in the NC system interface

- Mltor's series of motors is with anti-oil, corrosion protection

- Machine warranty period: 12 months once the customer receives machine, after 12 months, we may answer the customer's question on line or by e-mail within 24 hours

- Mltor will prepare one more set of quick-wear components with the machine for the customer

- Mltor will not provide or change any part or component for free if the customer damages them abnormally, customer needs to purchase them separately

- Mltor will afford the customer's technician local transportation, accommodation and catering cost when the customer's technician comes to Mltor factory to have a train or inspects the machine before the machine delivery and the customer will afford their technician travelling cost

- In the warranty period, if the customer requests Mltor engineer to support in foreign country, Mltor will supports to check equipment and train the customer technician for free but the customer needs to afford Mltor's engineer travelling expenses, local transportation and accommodation and catering cost.

| MLT-SK8V-1200 Processing specifications | |

| Number of spindles | 8 spindles |

| Number of axises | 10 axis |

| Drilling diameter | Ø1.0-Ø5.5mm |

| Maximum drilling thickness | ≤200mm |

| Maximum outer diameter of ring-die | Ø1200mm |

| Spindle travel range | ≤550mm |

| Spindle spacing range | 22.5° |

| Processing speed | |

| Max speed of revolution on drill pipe device | 30000 r/min |

| Feeding range | ≤1500mm/minute |

| Fast forward speed | ≤6000mm/minute |

| Precision of processing | |

| Drilling degree of skewness | ≤1/1000 |

| Drilling hole size precision | IT7-IT10 |

| Drilling hole wall roughness | Ra0.3-Ra0.8 (refer to marl 45, thermal refining) |

| Main device capacity | |

| Machine ultimate power | 60 KW |

| Spindle motor power | 4.6 KW x 8 |

| Oil pump motor power | 11 KW x 2 |

| Workpiece rotation & indexing electric device power | 2 KW |

| Feeding servo motor power | 1.5 KW |

| Oil cooling electric device power | 6 KW |

| Hydraulic system | |

| Maximum flow | 110L/minute |

| The highest pressure | 15MPa |

| Filtration accuracy | 10µm |

| Machine oil storage | 2000L |

| Machine data | |

| Machine size | 7000mmx7000mmx2800mm |

| Machine weight | 26500kg, hydraulic system is 1500kg |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Harry

- Address

- No.5,Feng Sheng Road,Torch Development Zone

- Product Category

- Machinery Tools

- Year Established

- 2012

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Offering Industrial Automation Control Machine and System

Mltor is a group that specializes in the research, manufacture and supply of industrial automation control machine and system, which is focusing on serving medium- and high-end equipment customers. We have developed whole series of machines in mold of feeding and biomass production field such as chamfering countersunk machine, one spindle and two spindles of outer drilling machine, flange drilling machine, four spindles of ring die drilling machine, grinding machine, ring die mold cleaning machine and compression gear hobbing machine. In China, more than 95% of feeding ring die enterprises already purchased Mltor machines. Among these enterprises, 68% of our customers have more than three sets of Mltor machine.

Get Benefited From Our Advantages

Mltor has obvious advantage on gun drilling especially four spindles of ring die drilling machine. We have sold out 70 sets of four spindles of ring die drilling machine in 2016. We expect to sale out 40 sets in 2017 till we launch new eight spindles of ring die drilling machine in July, 2017. Currently, there are 240 sets of four spindle of gun drilling machine in total and Mltor is keeping more than 40% of portion which is 100 sets in market.

We have strong competitive force since we launched the eight spindle of gun drilling machine last July, which promotes drilling speed double than four spindle of gun drilling machine. Meanwhile, we will research and launch mold cleaning machine and vertical drilling and milling machine in order for us to lead feeding ring die mold machine product on to higher level and marketing segmentation.

Trusted by Foreign Clients

Not only domestic clients but also more foreign clients trust Mltor machine and control system. We research not only hardware but also software CNC control system, which we may supply and lead customization software development for our client. So Mltor already exported chamfering countersunk machine and outer drilling machine to foreign client in 12 countries. We have exported four spindles of ring die drilling machine in June, 2017.

Our development direction in the future:- Research and produce special drill for 1mm even 0.8mm hole diameter ring die since drill of gun machine is easy to break, and not to mention more than 40pcs of drill to break for one gun machine per year.

- Research and develop ring die mold modification to help our client prolong ring die mold service life. Mltor already produced bigger hold diameter of gun drilling machine for our client. We will improve and customized CNC control system for our client ulteriorly.

- Sub-divide feeding ring die mold making process continually to improve the linkage of whole feeding ring die mold processing machine.

- Main Markets

-

Bangladesh

Bangladesh

Cambodia

Cambodia

China

China

India

India

Indonesia

Indonesia

Malaysia

Malaysia

Nepal

Nepal

North Korea

North Korea

Pakistan

Pakistan

Philippines

Philippines

- Main Product

Related Products

_2.jpg)

SHRINK FIT HOLDER(SLIM / STANDARD)

_2.jpg)

Smartphone Assembly System with air pressing (RG-260)

TCT Circular Saw Blade

MSX1000, Spin Coater Developer System

Heavy duty rebar Cutter