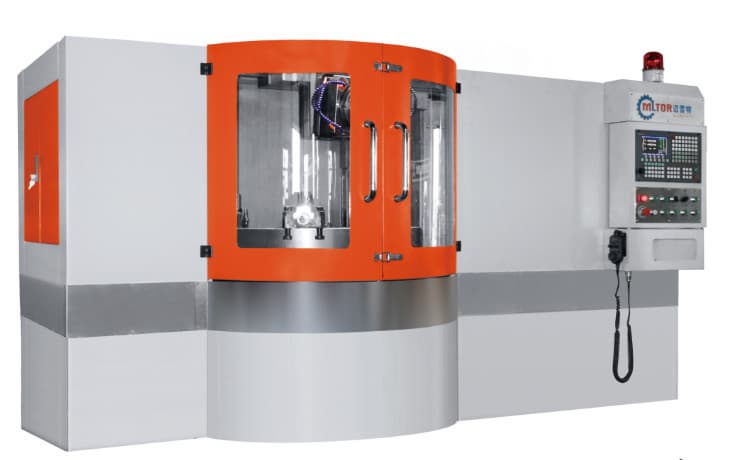

Digital Pellet Ring Die Vertical Turning Lathe Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MLTOR

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Machinery Tools

Zhongshan Mltor Intelligent Equipment Co.,Ltd

- Verified Certificate

-

7

| Product name | Digital Pellet Ring Die Vertical Turning Lathe Machine | Certification | - |

|---|---|---|---|

| Category | Machinery Tools | Ingredients | - |

| Keyword | high precision , vertical turning lathe , pellet dies lathe , blank rough turning | Unit Size | 3485.0 * 2570.0 * 4300.0 mm |

| Brand name | MLTOR | Unit Weigh | 10100 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Introduction:

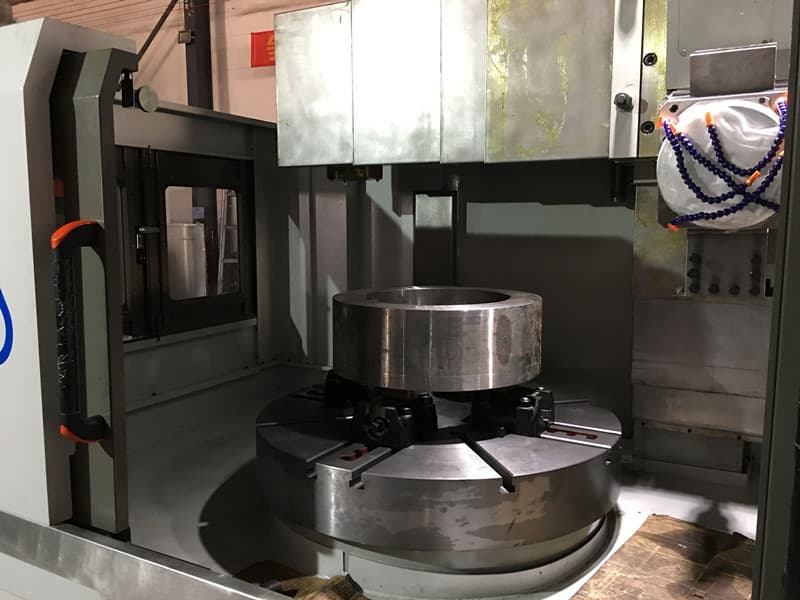

MLT-CK5112 is suitable for ring-die blank rough turning, semi-finish turning and finish turning and it is also suitable for inner and outer cylinder cutting, conicalness-shape cutting, end-face turning, grooving cutting of large component

Equipment features:

- Best ideal machine for ring die turning and lathe

- High rigidity, high precision, high efficiency

- Simple to clamping, operation is easy

- Long service life

- May implement integrate machining such as rough turning, semi-finish turning and finish turning together

- NC system MLT-T208V is researched and produced by our company with unique advantage as: easy operation, user-friendly, no programming which just input the needed parameter, stable performance and intuitive interface

- Machine warranty period: 12 months once customer receives machine, after 12 months, we may answer the customer's question on line or by Email within 24 hours

- Mltor will prepare one more set of quick-wear components with the machine for the customers

- Mltor will not provide or change any part or component for free if the customer damages them abnormally, customer's needs to purchase them separately

- Mltor will afford the customer's technician local transportation, accommodation and catering cost when the customer's technician comes to Mltor factory to have train or inspects the machine before the machine delivery

- Customer's will afford their technician travelling cost, in warranty period, if the customer's requests Mltor engineer to supports in foreign country, Mltor will supports to check equipment and train customer's technician for free but customer's needs to afford Mltor's engineer travelling expenses, local transportation, accommodation and catering cost

| CK5112 specifications | |

| Max cutting work piece diameter | 1200mm |

| Workbench diameter | 1010mm |

| Max work piece height | 1000mm |

| Max work piece weight | 5000kg |

| Max torque of workbench | 12.5kN/m |

| Circular speed grade of workbench | Grade II with stepless |

| Circular speed range of workbench | 1-200 r/minute |

| Max cutting force of vertical cutter frame | 20kN |

| Cutter frame feeding grade | Stepless |

| Cutter frame feeding range | 0.2-500 mm/minute |

| Vertical cutter frame | 650mm |

| Vertical cutter frame horizontal travel | -20-700mm |

| Cutter frame moving speed | 2000mm/minute |

| Beam moving range | 760mm |

| Ram size | 190x300mm (T-style RAM) |

| Max height of cutter bar cross section | 40mm |

| Main motor power | 22kW |

| Beam lifting motor power | 2.2kW |

| NC system | MLT-T208V |

| Machine size | 3485x2570x4300mm |

| Machine weight | 10100kg |

| Languages | Chinese/English |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Harry

- Address

- No.5,Feng Sheng Road,Torch Development Zone

- Product Category

- Machinery Tools

- Year Established

- 2012

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Offering Industrial Automation Control Machine and System

Mltor is a group that specializes in the research, manufacture and supply of industrial automation control machine and system, which is focusing on serving medium- and high-end equipment customers. We have developed whole series of machines in mold of feeding and biomass production field such as chamfering countersunk machine, one spindle and two spindles of outer drilling machine, flange drilling machine, four spindles of ring die drilling machine, grinding machine, ring die mold cleaning machine and compression gear hobbing machine. In China, more than 95% of feeding ring die enterprises already purchased Mltor machines. Among these enterprises, 68% of our customers have more than three sets of Mltor machine.

Get Benefited From Our Advantages

Mltor has obvious advantage on gun drilling especially four spindles of ring die drilling machine. We have sold out 70 sets of four spindles of ring die drilling machine in 2016. We expect to sale out 40 sets in 2017 till we launch new eight spindles of ring die drilling machine in July, 2017. Currently, there are 240 sets of four spindle of gun drilling machine in total and Mltor is keeping more than 40% of portion which is 100 sets in market.

We have strong competitive force since we launched the eight spindle of gun drilling machine last July, which promotes drilling speed double than four spindle of gun drilling machine. Meanwhile, we will research and launch mold cleaning machine and vertical drilling and milling machine in order for us to lead feeding ring die mold machine product on to higher level and marketing segmentation.

Trusted by Foreign Clients

Not only domestic clients but also more foreign clients trust Mltor machine and control system. We research not only hardware but also software CNC control system, which we may supply and lead customization software development for our client. So Mltor already exported chamfering countersunk machine and outer drilling machine to foreign client in 12 countries. We have exported four spindles of ring die drilling machine in June, 2017.

Our development direction in the future:- Research and produce special drill for 1mm even 0.8mm hole diameter ring die since drill of gun machine is easy to break, and not to mention more than 40pcs of drill to break for one gun machine per year.

- Research and develop ring die mold modification to help our client prolong ring die mold service life. Mltor already produced bigger hold diameter of gun drilling machine for our client. We will improve and customized CNC control system for our client ulteriorly.

- Sub-divide feeding ring die mold making process continually to improve the linkage of whole feeding ring die mold processing machine.

- Main Markets

-

Bangladesh

Bangladesh

Cambodia

Cambodia

China

China

India

India

Indonesia

Indonesia

Malaysia

Malaysia

Nepal

Nepal

North Korea

North Korea

Pakistan

Pakistan

Philippines

Philippines

- Main Product

Related Products

Bending Machine Tool

Rebar bender, bending machine, 1" inch 25mm Steel

Portable Rebar Cutter

UIM2901-5A MACH3 break out board for CNC

Bench Brake Disk & Drum Lathe DBL-STAR DLX