50-3000tpd Cement Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Mining Machinery

zk corp

- Verified Certificate

-

8

| Product name | 50-3000tpd Cement Production Line | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | cement production line , mcement production lineinin | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Main Materials:

Limestone, Clay, Gypsum, Fly Ash, Slag

We provide the full range service including

design, manufacturing, and installation. We design and manufacture equipment

for new type dry method cement production line, for which the capacity varies

from 50t/d to 3000t/d

OUR ADVANTAGE

1. High Efficiency

Cement production line adopts advanced

technology and equipment to raise technical level and to ensure design indexes.

New five-stage cyclone pre-heater system, high efficiency air girder grate

cooler, multi-passage pulverized coal burner, Davison heat temperature fan, jet

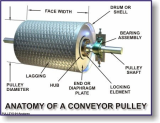

pulse dust collector, as well as chain-board elevator, chain conveyor adopted

in this production line can ensure that the technology is advanced compared to other

production lines with the same scale.

2. Saving Energy

Measures have been taken to save energy and

reduce consumption. Using chain-board elevator and air slides, reliability of

the system is enhanced and conveying energy consumption is decreased.

3. Environmental protection

Effective measures have been taken to

guarantee strict environment protection standards. Different efficient dust

collectors are set at all dust producing points according to different

characteristics of waste gas.

4. High degree of automation

There is no manual operation in the process

of mill running, which realizes the automatic control with long-term, stable,

effective, makes milling process more stable, realizes fine work of production.

PRODUCTION TECHNOLOGY

Mined limestone is delivered to the crusher

for crushing by the belt conveyor, limestone after crushing ,clay, iron powder

etc will be ground into powder by ball mill or vertical mill, and then

transported by air delivery chute to raw meal homogenization silo for storing

and further material mix. Raw meal shall get into the preheating decomposition

system after homogenization where decomposition rate is about 95%, and raw meal

is calcined into clinker in the rotary kiln, the formation of clinker. Clinker,

gypsum and mixture is ground into qualified fineness cement in the cement mill.

Powder classifier is adopted to adjust the fineness of cement, realizing energy

saving production. Cement packing machine and automatic loading machine are

used for bagged cement delivery, and cement bulk device for cement canning

leaving factory.

CONFIGURATION:

Dry process cement production line (25-200t/d)Configuration

|

Clinker capacity Equipment Parameters |

25t/d |

50 t/d |

100 t/d |

150 t/d |

200 t/d |

|

|

Rotary kiln |

Specification |

Φ1.4×33m |

Φ1.6/1.9×36m |

Φ2.2×45m |

Φ2.5×50m |

Φ3×60m |

|

Capacity |

1t/h |

2t/h |

4t/h |

6t/h |

8t/h |

|

|

Calcination Temperature (℃) |

1450 |

1450 |

1450 |

1450 |

1450 |

|

|

Raw mill |

Specification |

Φ1.2×4.5m Open circuit |

Φ1.5×5.7m Open circuit |

Φ1.83×6.1m Open circuit |

Φ1.83×6.1m Closed circuit |

Φ2.2×6.5m Closed circuit |

|

Capacity |

1.7t/h |

4.5t/h |

9t/h |

12t/h |

16t/h |

|

|

Motor power |

55kW |

130kW |

210kW |

210kW |

310kW |

|

|

Cement mill |

Specification |

Φ1.2×4.5m Open circuit |

Φ1.5×5.7m Open circuit |

Φ1.83×6.1m Open circuit |

Φ1.83×6.1m Closed circuit |

Φ2.2×6.5m Closed circuit |

|

Capacity |

1.4t/h |

3.5t/h |

6.5t/h |

8t/h |

12t/h |

|

|

|

Motor power |

55kW |

130kW |

210kW |

210kW |

310kW |

New dry process cement production line

(300-1500t/d) configuration

|

Clinker Capacity Parameters |

300t/d |

700 t/d |

1000 t/d |

1500 t/d |

|

|

Pre-heater |

C1 |

2-Φ2500 |

Φ3500 |

Φ4800 |

2-Φ4000 |

|

C2 |

Φ3600 |

Φ4800 |

Φ4800 |

Φ5800 |

|

|

C3 |

Φ3600 |

2-Φ3700 |

Φ5200 |

Φ5800 |

|

|

C4 |

Φ3600 |

Φ4800 |

Φ5200 |

Φ6200 |

|

|

C5 |

Φ3600 |

Φ4800 |

Φ5200 |

Φ6200 |

|

|

Pre-calciner |

Specification |

Φ2200 |

Φ2800 |

Φ4800 |

Φ5200 |

|

Rotary kiln |

Specification |

Φ2.8×44m |

Φ3×48m |

Φ3.2×50m |

Φ3.5×54m |

|

Capacity |

12.5t/h |

30t/h |

42t/h |

63t/h |

|

|

Calcination temperature (℃) |

1450 |

1450 |

1450 |

1450 |

|

|

Raw mill |

Specification |

Vertical roller mill Φ1700 |

Dry mill Φ3.2×7+1.8m |

Dry mill Φ3.5×10m |

HRM2800 Vertical roller mill |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- sugenghua

- Address

- Qiaolou CaizhaiIndustiral Estate

- Product Category

- Mining Machinery

- Year Established

- 1999

- Company introduction

-

It is appointed as the fixed equipment-providing factory by Chinese Ministry of Machine Building and HENAN Mechanical Electronic Bureau. The development during the last half century has witnessed its capital assets being over RMB100000000 and becoming a comprehensive modern enterprise with the service of scientific research, design, manufacture, sales, installation, commissioning and worker training. The production lines provided by us mainly include: Magnesium Production Line, Cement Production Line, Lime Production Line, Ore Dressing Line, and Oil Proppant Production Line, Main products include: Rotary Kiln, Ball Mill, Granulator, Bucket Elevator, Vertical Preheater, Vertical Cooler, Crusher.

- Main Product

China

China

_2.jpg)