Stainless Steel Warm Edge Spacer Forming Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- HGIT

- Payment Terms

- L/C

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other General Industrial Equipment

Dalian Huagong Innovation Technology Co., Ltd.

- Verified Certificate

-

11

| Product name | Stainless Steel Warm Edge Spacer Forming Machine | Certification | - |

|---|---|---|---|

| Category | Other General Industrial Equipment | Ingredients | - |

| Keyword | stainless steel warm edge spacer forming machine | Unit Size | - |

| Brand name | HGIT | Unit Weigh | 500 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

1)、Price

|

Model: HG-FS |

(9A/12A/14A/16A/18A/20A/24A)

Price (CNY):2,160,000.00

Note: 1. Including VAT, packaging, shipping and insurance costs

2. The specific model according

to the customer’s choice, one set of equipment can choose one size of warm edge

spacer

2)、Introduction

The warm edge spacer forming machine is used for processing complete

stainless steel panel, and was developed by the R&D team at Dalian Huagong

Innovation Technology Co., Ltd (HGIT). The machine is the result of three years of

research and small batch trial production of ultra-thin stainless steel panels

through precision rolling and forming. After passing a series of rigorous

testing and inspection procedures, the equipment has been proven to fully

satisfy the demands of constant, continuous processing of warm edge spacers for

hollow glass with ultra-thin stainless steel bands. It also ensures an even and

regular geometric form for the warm edge spacer section after forming.

3)、Overview of

Functions

1、Automatic Uncoiling: 180º dual disc and dual shaft direction conversion,

quickly replacing the warm edge spacer band uncoiling mechanism

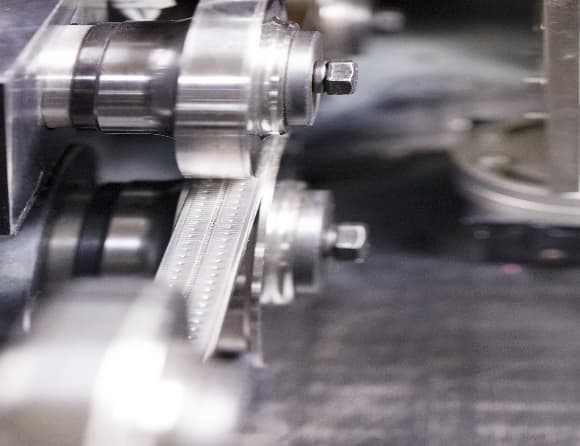

2、Roller Head Machine: the main component for rolling and forming the

ultra-thin stainless steel band (0.12-0.15mm), it comprises over 20 sets of

precise rolling wheels, and is driven by a servo motor. Fully adjustable speed

settings, thanks to the chain-driven design, ensure stable and reliable

operation of the machine

3、Forming Machine: the forming machine carries out3D forming, and is capable

of calibrating and straightening the warm edge spacer after rolling. Our

company holds an independent patent for this device

4、High Frequency Laser Spot Welder: the high frequency pulse laser spot

welder is capable of welding the warm edge spacer after rolling, and features a

solid welding spot and smooth welding seam

5、Flying cutter: synchronously cuts the warm edge spacer after dynamic

formation, at a high speed and to a specific size

4)、Technical

parameters:

|

Model |

HG-FS |

|

Section dimension |

15.5mm×6.5mm (for 16A) |

|

Processing speed |

0-- 12000mm/min |

|

Welding spots dimension |

0.5-1mm |

|

Welding spots distance |

1-2mm |

|

Main motor power |

5KW |

|

Machine power |

30KW (include 1 laser welder) |

|

Voltage |

380V |

|

Frequency |

50Hz |

|

Overall dimension |

15000mmx1000mm (exclusive laser welder) |

|

Floor space |

14m×2.5m |

Please note:

1. Each piece of equipment is only capable of processing warm edge spacers

of one specific shape and configuration

2. The processing speed depends on the speed of the laser spot welder, the

spot spacing and the quantity of laser welder used.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C | Shipping time | Negotiable |

- President

- Huagong

- Company introduction

-

Dalian Huagong Innovation Technology Co., Ltd was formally established in 2003, located in the beautiful coastal city-Dalian in China, which is an innovative and high technology industrial corporation gathering research and development, manufacturing, marketing and services.

The “Huagong HGIT” brand products of the company has passed ISO9001:2008 international quality system authentication and

won a number of national patents. Major products are: self-sealing automatic double surface gluer, heat insulation aluminum profile injecting production line (including aluminum profile potting machine, cutting bridge machine, gulleting machine and

two-tone compound machine), plates cementing and spreading device and customized automatic production line.

- Main Product

Related Products

SUBMERSIBLE PUMP

LIO FLEX Touch

K2UV SERIES UV MARKING LASER MACHINE

YN-COUPLINGS

High Pressure Spray Hose

China

China