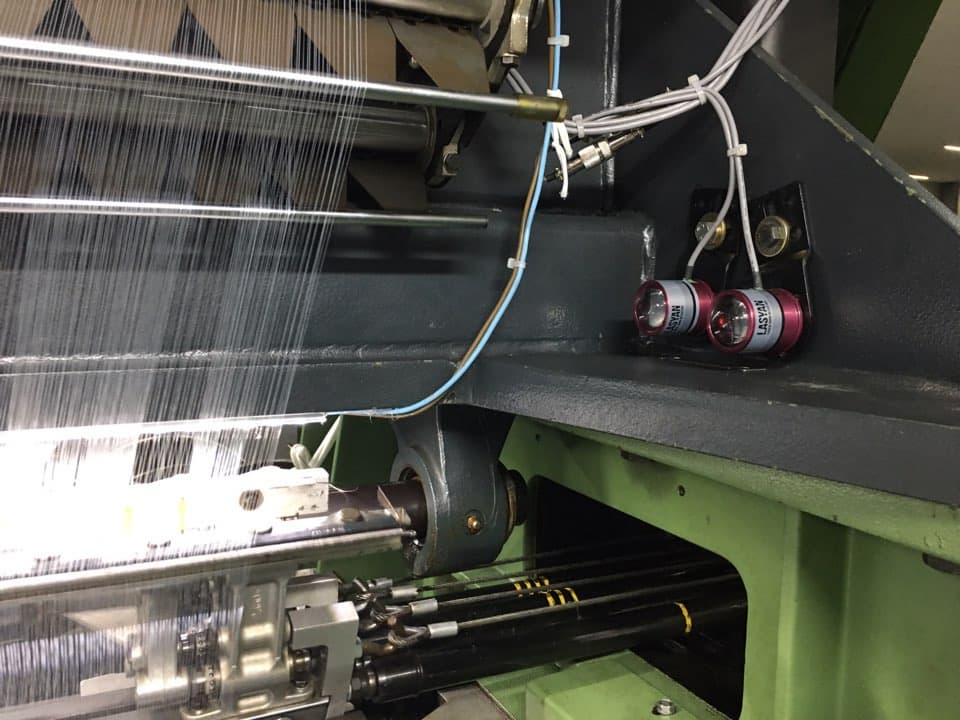

Yarn Break Detector_Yarn Break Laser Sensors: Made in Korea

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- LASYAN

- Payment Terms

- L/C,Others,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Textile Machinery , Sensors , Other Textile Machinery

Daelim Technology

- Verified Certificate

-

7

| Product name | Yarn Break Detector_Yarn Break Laser Sensors: Made in Korea | Certification | - |

|---|---|---|---|

| Category |

Textile Machinery

Sensors Other Textile Machinery |

Ingredients | - |

| Keyword | yarn break detector , tricot sensor , tricot machine sensor , broken yarn detector | Unit Size | 220.0 * 80.0 * 200.0 mm |

| Brand name | LASYAN | Unit Weigh | 5 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8543 |

Product Information

Tricot, Let's catch the cut,

lengthened of original string of Russel equipment with the Laser!

Yarn Break Detector_LA400

It is necessary laser detector in the fabric production of warp knitting machine, raschel machine, double needle bar warp knitting machine, Baird textile machine etc. The laser sensor will detect the break line or some other errors then stop the textile process. Copare with the previous product used infrared laser sensor our product is using the visible light sensor which can avoid the mis-operation. And the detector is developed by our company independently so the product maintenance is simple and effective. Broken yarn, sagging of the yarn, from now on Let’s catch by Laser.

1. Sensitivity Indicator

- It represents the sensitivity of each channel sensor. After rotating the rotary switch to the designated channel ch1, the button can be adjusted by rotating the corresponding channel's sensitivity, then, adjusting the sensitivity indicator turned on or turned off to the sensitivity of ch1 sensor. The manner of adjusting for ch2, ch3 is same with ch1.

2. Rotary Switch

- To toggle the rotary switch is the first step of adjusting the sensitivity of each channel sensor. When it is confirmed, toggling the rotary switch to the state of running.

3. Indicator

- It will be displayed in green color when it runs well while it will be displayed in red color when it detects line breakage.

4. Sensitivity adjustment button

- Each channel has corresponding sensitivity adjustment button, through the sensitivity adjustment button can adjust the sensitivity of corresponding channel sensor.

5. Channel switch

- Select each channel is working or not. In order to make the corresponding channel work, it is feasible to toggle switch to on state, on the contrary, make it to off state.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,Others,T/T | Shipping time | Negotiable |

- President

- Mr. An

- Address

- myungan-ro 71, 8rd ,dltkorea co., ltd., Dongnae-gu, Busan, Korea

- Product Category

- Textile Machinery

- Year Established

- 2005

- No. of Total Employees

- 1-50

- Company introduction

-

Thank you for interest our company.

Our value is "Quality and Technical Advancement".

We are preparing to penetrate the foreign market with more advanced technology that its excellence has been recognized by multiple domestic businesses.

With the first domestic invention of LASER yarn sensor; this would be the best product to maximize your company output.

- Main Markets

-

Hong Kong(China)

Hong Kong(China)

Indonesia

Indonesia

Japan

Japan

Malaysia

Malaysia

Myanmar

Myanmar

Singapore

Singapore

South Korea

South Korea

Taiwan

Taiwan

Viet Nam

Viet Nam

- Main Product

- Attached File

Related Products

K SERIES COLOR MARK SENSOR

DH05 SERIES MICRO SWITCH

CIRCULAR KNITTING NEEDLE

TLP185(GB-TPL,SE

Separated Fixed Ultrasonic Flowmeter