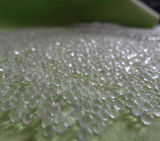

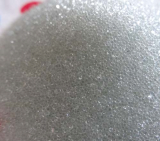

Mechanical Metal Spray Glass Bead Mold Sandblasted glassbead

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Xinxiang Best Glass

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- blasting glass beads, cleaning metal, mold sandblasted glass beads, hot-sale glass beads from china

- Category

- Abrasives

Xinxiang Best Glass Product Co.,Ltd

- Verified Certificate

-

7

| Product name | Mechanical Metal Spray Glass Bead Mold Sandblasted glassbead | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | blasting glass beads , cleaning metal , mold sandblasted glass beads , hot-sale glass beads from china | Unit Size | - |

| Brand name | Xinxiang Best Glass | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 70 |

Product Information

I. Introduction

With the development of production technology, more and more people have a better understanding of the blasting glass beads. The most accurate position of blasting glass beads is a material that pushes the abrasive material through the compressive force of air.

In the early days of blasting glass beads, its main abrasive material was sand, so it is called sandblasting. But this material is prone to abrade. Now in the market, shot blasting is the best and most reasonable technology. It can clean the steel surface well. It’s clean and thorough, and the use of the cost is relatively low.

Blasting technology can quickly make the surface of the required cleaning objects more smooth. For some upper coating, it can not be attached to the untreated surface for a long time, so sandblasting is essential. Processed objects can be a good color, and the color effect is relatively pure.

Ⅱ. The characteristics of blasting glass beads

1,Both have soft and hardness --- use high-quality materials to produce. It has a certain degree of mechanical strength (SiO2 content is more than or equal to 68%, the hardness can be 6-7 Mohs), but also has enough flexibility, and you can repeatedly use several times and it doesn’t easily broken.

2,Uniformity is good ---its round rate more than or equal to 85%, uniform size. After spray the sandblasting device throughout maintain the brightness coefficient , not easy to leave the watermark.

3,Irreplaceable - blasting glass beads as a grinding material has the following advantages than any other grinding materials : Except as metal grinding materials, it has a longer use time than any other medium. With non-alkaline sodium calcium glass material, it has good chemical stability. It will not pollute the metal and can speed up the cleaning, while maintaining the original processing accuracy of objects

4,Smooth and no impurities --- the appearance is spherical particle, no impurities, smooth surface, good degree of finish. It can reach international and domestic level.

Tel: 008613346677940 / 008613346677960

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- miao

- Address

- huanggang crossing XinXiang,henan,china

- Product Category

- Reflective Material

- Year Established

- 2015

- Company introduction

-

Xinxiang Best Glass Products Co., Ltd is a professional manufacturer dealing with glass beads for road marking, reflective glass beads, glass beads for traffic paints, grinding glass beads, glass beads for sandblasting, glass beads filler, hot melt coating glass beads, drop-on glass beads, intermix glass beads, two-component glass beads, large size colorful glass beads. We adopt advanced production technology at home and abroad. There are 10 production lines for the glass beads in our company, together with complete screening, matching, coating production facilities and advanced production technology. The annual output is more than 30,000 tons. My company's products through the EU CE certification. Our products are well sold in domestic market and exported to the United States, Canada, Japan, Korea, South Africa, Singapore, India, Germany and other regions, and our producits have got unanimous approval and favorable comment of the domestic and international customer.

- Main Product

Related Products

98% Black Silicon Carbide SiC for Abrasive Products

F12 F14 white alumina/F14 F20 white fused alumina

Diamond Polishing Slurry

_2.png)

Xonite Dendroid Brush(cleaning)

Cast Stainless Steel Shot

China

China