Steel Metal Stamping Die for Vehicle Parts Made in China

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Gold Lodestar Tool & Die

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Molds

Shenzhen Gold Lodestar Tool & Die Co., Ltd.

- Verified Certificate

-

8

| Product name | Steel Metal Stamping Die for Vehicle Parts Made in China | Certification | - |

|---|---|---|---|

| Category | Molds | Ingredients | - |

| Keyword | progressive die , stamping die , tooling die , sheet metal assemblies | Unit Size | - |

| Brand name | Gold Lodestar Tool & Die | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8207 |

Product Information

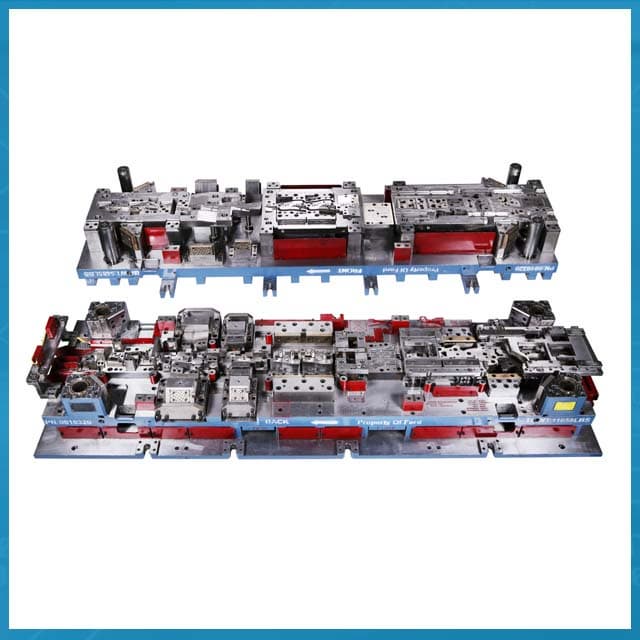

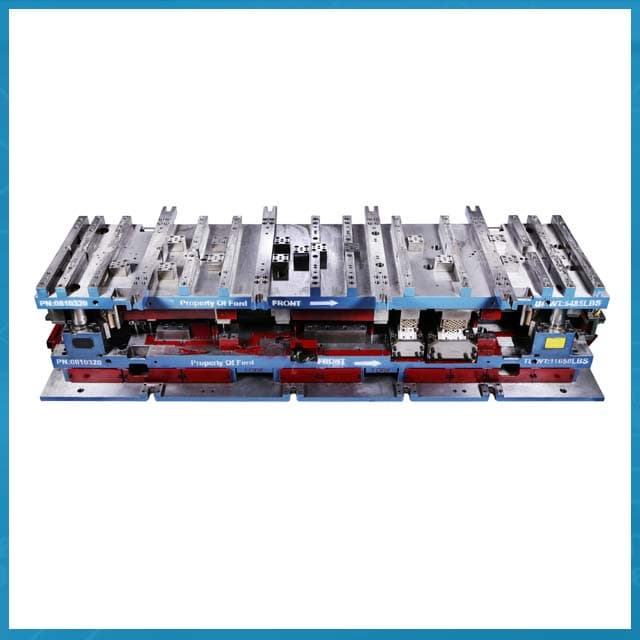

Steel metal die

Die Size:3000L*1000W*800H

· Tooling with insert construction to allow for the rapid component replacement required in high-wear production processes

· Complex forms that require coiling and varying material thicknesses in the final part

GLS Tool & Die can build dies up to 60” wide and 150” long (1500*3800mm), with an in-house tryout capability of 800T. We ensure all the tooling will be engineered to meet all stamping press specifications and die standard. We have expertise in developing innovative tooling solutions for these part materials: high-strength steel, stainless steel and aluminum.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Mr. Meng

- Address

- Yanchuan, Songgang

- Product Category

- Molds

- Year Established

- 2006

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Stamping die supplier in Shenzhen.

Focused on the sheet metal stamping die design & manufacture since 1999.

Shenzhen Gold Lodestar Tool & Die Co., Ltd. established in 1999, which is a company specialized in design and manufacturing metal stamping die for sheet metal parts in 0.5-6mm thickness.

(Web showcase: www.idealtooling.com, you can contact me at abby@glmetal.com, also info@idealtooling.com. )

Tooling Project:

Progressive die

≤1200 ton progressive tooling projects, home tryout below 800 ton equipped with three-in-one feeder, max. width 1000mm. The maximum tool we can make is : 4000X1800X1000mm. Our tools are mostly exported to Europe, North&South America.

Transfer die

Multi-station transfer tool and multi-press transfer tool. Multi-station transfer tool is suitable for small parts like auto seating parts. Multi-press transfer tool is suitable for big parts like auto chassis, bumper. These tools is mostly supplied to Japanese car models or domestic auto joint manufactures.

Single die

Short run deep-drawing single tool and manual multi-station single tool. This kind of tools mostly is casting iron tool, tooling for complex parts. In some single tools, we can add electrical control system ,so the tools can produce the parts of different sizes, thus to decrease the tooling cost, and also to increase the tool capacity.

If you have any interested in the above products or have requirement service, please do not hesitate to contact with us.Our Customers

We are honored to supply stamping dies for lost of the world’s leading brands including Ford, Land Rover, Toyota, Honda, Magna, Flex N Gate, CovpressHolding, Sertec, Ricor, Walker Corporation etc… …

Dies are widely exported to the whole world (such as America, Canada, UK, Germany, France, Czech, Brazil, Mexico, Japan, Turkey, India, etc.)

- Main Markets

-

Australia

Australia

Canada

Canada

China

China

Czecho Republic

Czecho Republic

Egypt

Egypt

France

France

Germany

Germany

Spain

Spain

Turkey

Turkey

U.S.A

U.S.A

- Main Product

Related Products

PLASTIC INJECTION MOLD : AUTOMOTIVE PARTS (exterior)

Mobile power supply, custom mobile power supply, power

chemical foam agent for leak stoppage

Sand Mold

PVC/Vinyl Wire End Caps