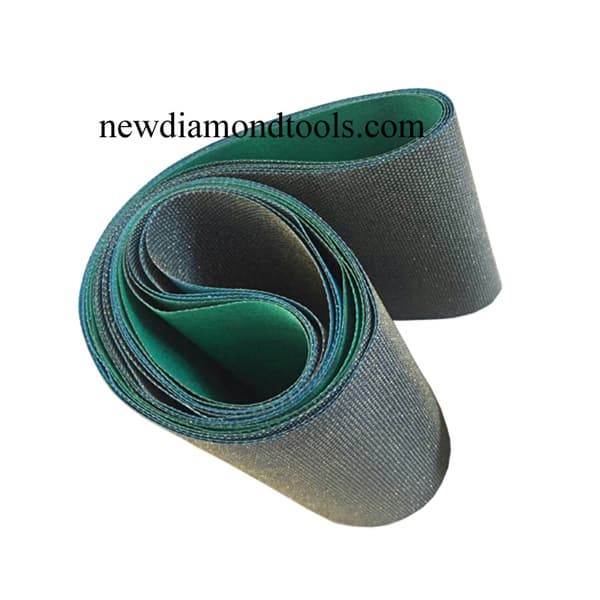

CBN abrasive belts

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- xinzuan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Xinxiang New Zuan Diamond Tools Co., Ltd

- Verified Certificate

-

8

| Product name | CBN abrasive belts | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | cbn belts , cbn grinding belts , cbn abrasive belts , cbn grinding abrasive belts | Unit Size | - |

| Brand name | xinzuan | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

CBN grinding abrasive belts has high efficiency grinding, good wear resistance, high quality surface process and friendly environmental. The hardness of CBN is less than diamond, but the thermal stability of that is much higher than diamond. It has a greater chemical intertia for Fe family of metal and alloy tools

Features of CBN

1, The hardness of CBN is much higher than ordinary abrasives. Especially for processing high hardness, toughness, high temperature, high strength, low thermal conductivity of the material. The metal grinding rate of CBN is 10 times of the diamond.

2, CBN abrasive grinding performance is very excellent, not only capable of grinding materials that is difficult to work, improve production efficiency, but also conducive to strictly control the shape and size of the workpiece precision, and effectively improve the grinding quality, significantly improve the grinding the surface integrity of the tool, thus increasing the fatigue strength of the part, extending the service life and increasing the reliability.

3, CBN abrasive grinding has wear less, long cycle, grinding ratio is relatively high, and has a reasonable economic result.

4, The shape and size change of CBN abrasive is extremely slow when using, which is more suitable for CBN CNC machining high-precision parts.

5, It can maintain a sharp grinding force for long time, so the grinding force is small. It is better for improving accuracy of parts and finish. and also can reduce the power consumption of machine tools.

6, The grinding temperature is low, can greatly improve the surface quality of the workpiece, to avoid parts of cracks, burns, changes in tissue , improving the processing of surface stress, it is good for the extension of the life of parts.

7, Ordinary abrasive belt produce a lot of dust when using, it is harmful to human health. It will cause silicosis if long term use.

.

Specification CBN abrasive grinding belt

Grit:40#-5000#

Width:5-30mm

Length: 150mm-5000mm

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Owen Wang

- Address

- 18# Jingu Orential Piazza, Jinsui Road, Xinxiang, Henan 453000, China

- Product Category

- Abrasive Tools

- Year Established

- 2015

- Company introduction

-

Xinxiang New Zuan Diamond Tools Co., Ltd is a professional diamond tools and CBN tools supplier, the main production diamond saw blade, diamond polishing pad, diamond grinding wheel, diamond drill, diamond brush, CBN products, products are widely used in stone industry, ceramics industry, glass industry, magnetic materials and automotive industryResin bond diamond/CBN grinding wheelMetal bond diamond/CBN grinding wheelVitrified bond diamond/CBN grinding wheelDiamond /CBN honing stoneDiamond grinding wheel for optical glassDiamond grinding wheel for silicon waferDiamond grinding wheel for crystal glassDiamond grinding wheel for fiber ceramicDiamond grinding wheel for PCD,PCBN toolsDiamond grinding wheel for hard carbideDiamond grinding wheel for sapphireDiamond grinding wheel nature diamondDiamond polishing pad for stone,concrete,terrazzoDiamond /CBN abrasive beltDiamond saw bladeDiamond core drill bitDiamond abrasive brush

- Main Product

China

China

_2.jpeg)