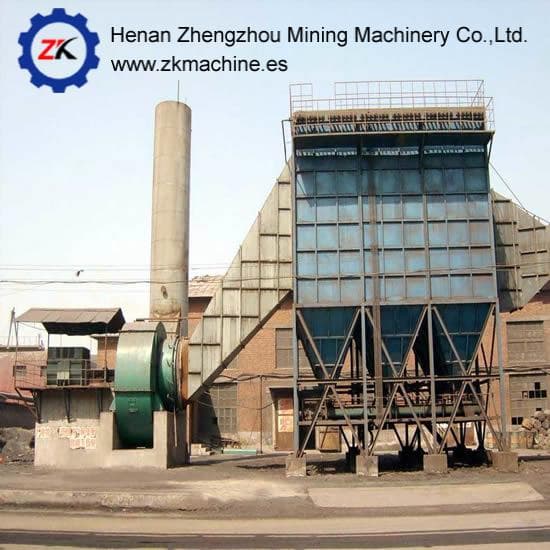

Industrial Dust Collector bag filter machine and system

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Mining Machinery

Henan Zhengzhou Mining Machinery Co.,Ltd.

- Verified Certificate

-

8

| Product name | Industrial Dust Collector bag filter machine and system | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | bag filter , dust collector , bag filter collector , dust collector system | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

1.

Introduction

Dust

collector is commonly used in boilers and industrial production facilities. The

dust is separated from the flue gases out of the device called dust or dust

removal equipment. Precipitator performance with the amount of gas that can be

processed, expressed by gas pressure loss and collection efficiency of dust

when. Meanwhile, the price of dust, operation and maintenance costs, length of

life and ease of operation and management is considered an important factor in

its performance. Has a national post-doctoral workstations, developed dozens of

patented technology, access to a number of national R & D funding dust.

2.

Aplication

Dust

collector is used in the following applications:

√ Woodworking

√ Cement production

√ Powder processing

√ Steel melting

√ Material handling

√ Primary metals, including steel-making

√ Metals fabrication: grinding, sawing, sanding,

polishing

√ Papermaking

√ Mixing and blending options

√ Mining

√ Foundries

√ Glass Plants

√ Battery Plants

3.

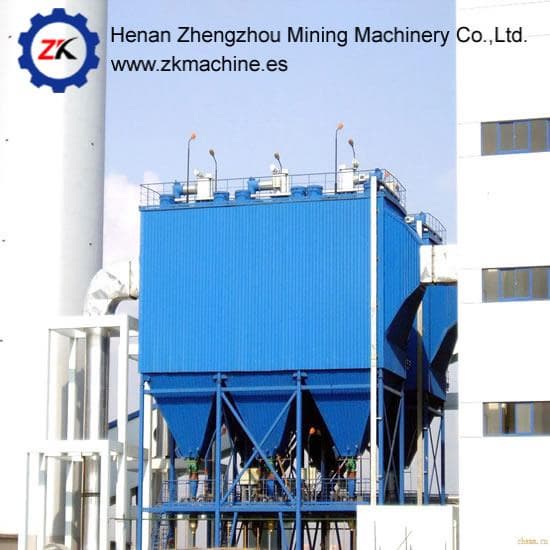

Feature

(1)

It has modern design, it uses lower gas inlet structure, the rough high

temperature granules directly drop to the dust hopper and effectively protects

the filter bag.

(2)

It uses long filter bags and it has smaller floor area in case of equal

processing capacity, therefore it is more convenient for reconstruction of old

factories.

(3)

It uses separate chamber offfline dust clearingwith high efficiency and few

secondary flour dust attachment, in the meantime, it can effectively reduce the

equipment energy consumption, the fatigue level of filter bag and pulse valve

is correspondingly reduced and the service life of filter bag and vane is

prolonged by several times and equipement operation cost is remarkably reduced.

(4)

The overhaul and bag replacement can be carried out for separate chambersunder

the condition that system blower and system run normally.

(5)

The filter bag inlet used spring tension structure, it is convenient to

disassemble & assemble and it has good tightness.

(6)

The case uses airtightness designand it carries out leak detecting with oil and

reduces air leak to the maximum extent.

(7)

The whole set of equipment is controlled by PLCto realize automatic dust

cleaning, dust removal, automatic temperature control and over temperature

alarm.

If you are interested in the products of our company,

please contact us to get the quote.

WhatsApp: +8615237956296

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- sugenhua

- Address

- Qiaoloucaizhai industrial park, XingYang,ZhengZhou,Henan,China

- Product Category

- Mining Machinery

- Year Established

- 1956

- Company introduction

-

HENAN ZHENGZHOU MINING MACHINERY CO.,LTD is leading mining equipments manufacturing in the world, who has provided innovative technology and products for mine and energy of over 100 countries and district. It is built in 1956 and locates its factory in XINNGYANG, HENAN, China. It is appointed as the fixed equipment-providing factory by Chinese Ministry of Machine Building and HENAN Mechanical Electronic Bureau.The development during the last half century has witnessed its capital assets being over RMB100000000 and becoming a comprehensive modern enterprise with the service of scientific research, design, manufacture, sales, installation, commissioning, worker training and etc.The production lines provided by us mainly include: Magnesium Production Line, Cement Production Line, Lime Production Line, Ore Dressing Line, and Oil Proppant Production Line; Main products include: Rotary Kiln, Ball Mill, Granulator, Bucket Elevator, Vertical Preheater, Vertical Cooler, Crusher, Metallurgy Coke Oven, Magnetic Separator, Flotation Machine, Classifier, Feeder, Dust Collector, Cooler, Dryer, and etc. Our products are sell well in each city in China and could also be found in Russia, South Korea, Vietnam, Malaysia, Nepal, Bengal, Mexico, Armenia, Africa, South America, and etc, which are thought highly by our clients.

- Main Product

China

China