ALUMINIUM FORMWORK

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Innovative formwork system

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Formwork , Aluminum Composite Panels

ALUFORMS KOREA CO., LTD.

- Verified Certificate

-

16

| Product name | ALUMINIUM FORMWORK | Certification | - |

|---|---|---|---|

| Category |

Formwork

Aluminum Composite Panels |

Ingredients | - |

| Keyword | construction materials , formwork system , aluminium formwrok , aluminiium panels | Unit Size | - |

| Brand name | Innovative formwork system | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8480600000 |

Product Information

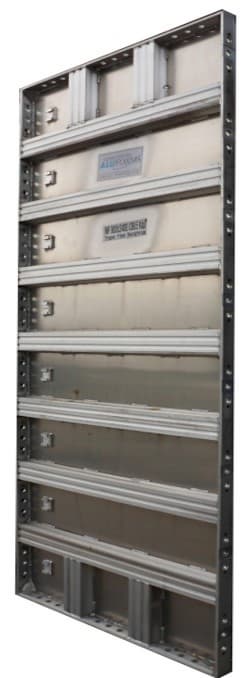

* What is Aluminium Formwork?

- Construction system for forming cast in place concrete structure of a building

- The panels are made from high strength aluminium alloy

- The face or contact surface of the panel is made up of 4 mm thick plate.

- The walls are held together with high strength wall ties, while the decks are supported by beams and props.

- The panels are held in position by a simple pin and wedge arrangement system

* Innovation in Forming concrete structure

- A versatile solution for forming concrete structures in a cost effective and efficient manner.

- It is a system for scheduling and controlling the work of other construction trades such as steel reinforcement, concrete and M&E.

- It forms all of the concrete in a building including walls, floor slabs, columns, beams, stairs, etc according to architects' design.

- It can be easily applied to simple column, beam and slab constructions.

* Why use Aluminium Formwork?

- Quality

: it gives construction structure a very high quality finish and leaves no deflection, creating evenness, eventually adding style and stability.

- Speed

: Compared to conventional construction procedures, reduces floor completion cycle from 15 days to 4 to 5days.

- Safety

: Worker can safely work on it due to light weight panel.

- Cost effective

: Lesser manual labor which reduces labor expenses. Post-construction cost is also reduced due to excellent concrete construction quality.

- Durability

: It can be reused repeatedly without getting rusty.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- SONG YOUNG S.

- Address

- 749-10, Chogeum-ro, Geumwang-eup, Eumseong-gun, Chungbuk, 27639, Korea

- Product Category

- Formwork

- Year Established

- 2001

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

Aluminum formwork was invented in the 1962. After more than 50 years of development, it has been widely used in the United States, Canada, Europe, HK, Macao, India, Malaysia, South Korea, Brazil, Vietnam, and other many countries. The aluminum formwork is still the number one choice for concrete poured construction for any type of building and structure for massive housing projects include low rises and high rises.

After extensive research and development, we established ALUFORMS in the U.S. and ALUFORMS KOREA in 1998. Comparing to other types of formwork or competitor, our highly designed and precisely engineered formwork will give our clients confidence without any hesitation.

Throughout the years, we have provided over one hundred projects more than one million square meters including North, Central, South Americas, Asia, and Middle East countries. Besides the quality and efficiency, our aluminum formwork is the best investment in construction industry. As it gives you the freedom of flexibility in economic prospect by being able to let our clients to sell them as scrap, our products will stay in your hands as true value.

We promise to continue to thrive for quality, innovation, and services with our clients’ needs in mind.

- Main Markets

-

Malaysia

Malaysia

Thailand

Thailand

U.S.A

U.S.A

- Main Product

Related Products

sandwich panel(EPS, glasswool, urethane)

RC Level Rod

Aluminum-Form Level Rod

Aluminum Formwork System

form brace aligner,turnbuckle concrete

South Korea

South Korea