fused silica investment casting Grade

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- D/A,D/P,L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Refractory , Silica , Other Non-Metallic Mineral & Products

Chem&Size Minerals Limited

- Verified Certificate

-

7

| Product name | fused silica investment casting Grade | Certification | - |

|---|---|---|---|

| Category |

Refractory

Silica Other Non-Metallic Mineral & Products |

Ingredients | - |

| Keyword | fused silica , fused silica powder , fused silica flour , precision investment casting | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 320740 |

Product Information

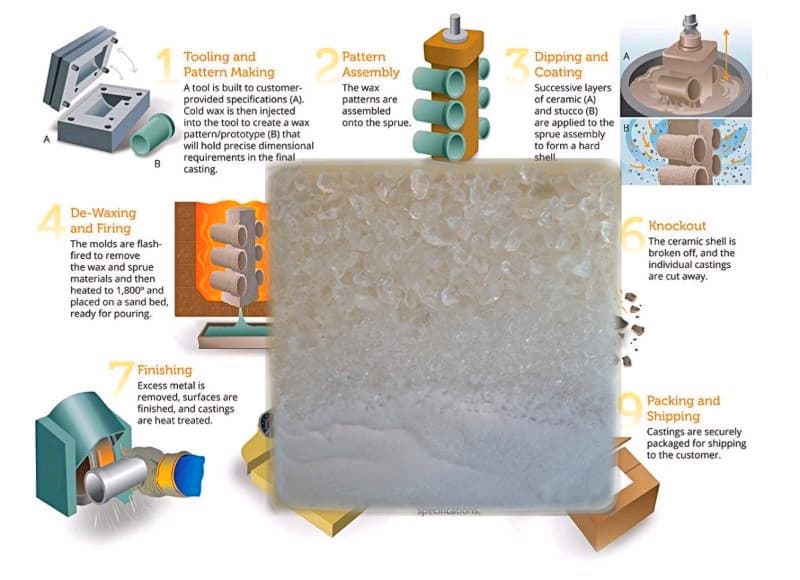

fused silica sand,fused silica grains,fused silica powder,fused silica sand can be made cearmic slurry and shell in the process of making investment casting.

Investment casting, also known as Precision casting or lost-wax process, is used to make precision products for the industiry of machine,automotive, military, aerospace, medical, commercial, and recreational.

Most investment casting foundries use Zircon Flour for making the primary slurry. Zircon continues to be in short supply and the prices are rising. Many clients use the Fused Silica sand,used silica powder,fused silica grains,fused silica flour in the dipping and coasting process to make primary slurry and rainfall sander to form a hard shell because of the following advantages:

1) Fused silica decrease in material consumption

Fused Silica's density is 2.21g/cm3,just roughly half of Zircon's density. If Zircon flour is replace 20% in primary slurry batch with Fused Silica, it needs lesser material by weight. For example if slurry mix had 50 kgs of Zircon and try and replace 10 kgs then it would need to add around 6 kgs of Fused Silica flour to achieve the existing viscosities and flow properties.

2) Fused silica increase permeability and porosity

Zircon is very dense. Fused Silica is lighter and does not pack as tightly as Zircon which is why it helps in improving the permeability of your shell. It is also more porous.

3) fused slica ceramic shell is Easier knock-out

Fused Silica knocks out much easier than Zircon or Alumino-Silicates. This is because of the Cristobalite formation while pouring which easily breaks down upon cooling.

4) Faster leaching and shell removal

the moment to add fused silica in the shell it helps in the leaching process and it is much easier to remove shell materials off cavities and holes.

5) Fused Silica price is cheaper.

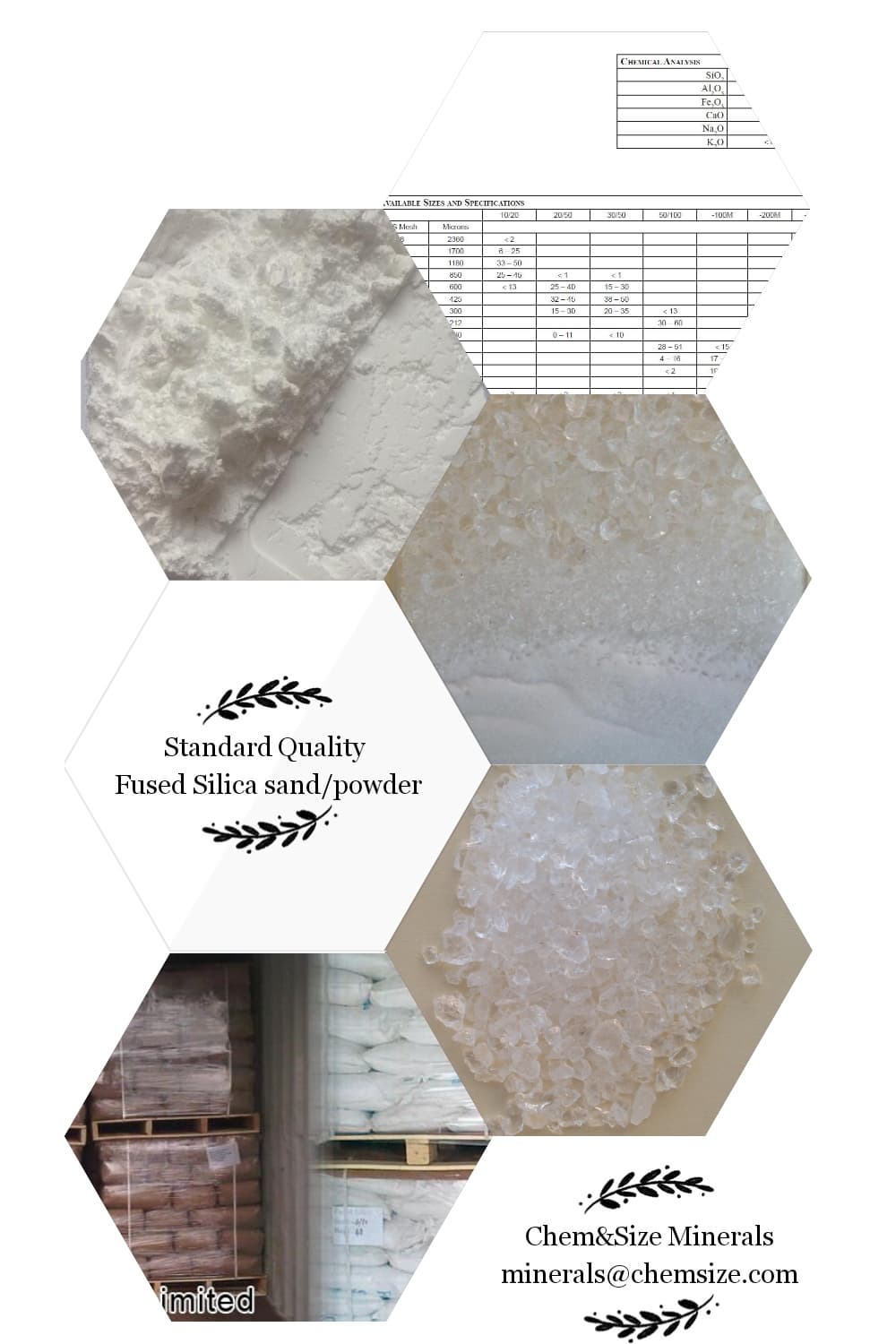

The typical specification sheet of Chem&Size minerals Fused Silica sand,fused silica grains and fused silica powder and fused silica flours for your perusal.

1. | Physical Properties | ||

1.1 | Composition | SiO2 | |

1.2 | Structure | Amorphous | |

1.3 | Colour | Transparent or white | |

1.4 | Melting Temperature | approx.1750℃ | |

1.5 | Specific Gravity | 2.21g/cm3 | |

1.6 | Hardness | 7 Mohs | |

1.7 | Thermal Expansion | 0.5*10-6 | |

2. |

Chemical Properties | ||

|

| Investment Casting Grade | |

2.1 | SiO2 | >99.90% | |

2.2 | Al2O3 | <200ppm | |

The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

2.3 | Fe2O3 | <50ppm | |

2.4 | TiO2 | <20ppm | |

2.5 | MgO | <40ppm | |

2.6 | CaO | <40ppm | |

2.7 | Alkalies Na2O+K2O | <100ppm | |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,T/T | Shipping time | Negotiable |

- President

- Frank Wang

- Address

- Haikeyinzhou, Haitang Bei Lu 89#,Lianyun District

- Product Category

- Silica

- Year Established

- 2012

- No. of Total Employees

- 1-50

- Company introduction

-

Chem&Size Minerals Limited were established with aim not only to engrosse in good and stable quality fused silica, but also devoted to reduce their cost. Hundreds of thousands of Tons per year Fused silica were made in China Mainland. 95% of them were produced in Donghai and XInyi city and 100, 000Tons level fused silica were exported world wide through LIANYUNGANG Port to refractory, investment casting, foundry, advance fused silica ceramic, powder coatings, epoxy molding compound and other industry fields. Due to Chinese fused silica speical fusion or melting technology, fused silica must be divided into several grades by manual so that their quality are uneven. To solve this problem, Chem&Size Minerals Limited control chemcial composition, particle size distribution and amorphous phase of fused silica and further to export qualified and stable fused silica.

- Main Markets

-

Austria

Austria

Belgium

Belgium

Czecho Republic

Czecho Republic

Germany

Germany

Italy

Italy

Oman

Oman

Saudi Arabia

Saudi Arabia

Spain

Spain

Turkey

Turkey

U.A.E.

U.A.E.

- Main Product

Related Products

Ceramic Valve Seats

Talc Chalk,Talc Sticks

High Alumina Bricks

Hot Pressed Hexagonal BN Boron Nitride Ceramic Crucible

gold melting induction furnace graphite crucible

China

China