Ammoxidation catalyst (titanium silicon molecular sieve (TS-1)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China,India,Indonesia,Japan,South Korea

- Payment Terms

- T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- catalyst, silicon, titanium, melecular sieve

- Category

- Organic Acid

Zibo Hengyi Chemical Science and Technology CO.,Ltd

- Verified Certificate

-

8

| Product name | Ammoxidation catalyst (titanium silicon molecular sieve (TS-1) | Certification | - |

|---|---|---|---|

| Category | Organic Acid | Ingredients | - |

| Keyword | catalyst , silicon , titanium , melecular sieve | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China,India,Indonesia,Japan,South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Ammoxidation catalyst has a three-dimensional pore structure is composed of two sets of ten membered ring channel and a set of ninemembered ring channel interleaving composition, molar group hasbecome (0.001 ~ 0.2) TiO2: SiO2.

Ammoxidation catalyst is Ti atoms replace part of aluminum atoms insilicon aluminium molecular sieve and into, which belongs to ZSM-5 series zeolite molecular sieve, with the MFI structure, composed ofsilicon oxygen tetrahedron and titanium oxygen tetrahedron primarystructural unit, connecting through the oxygen bridge, constitute asecondary structure unit of five membered rings, and further to form a three-dimensional porous skeleton, pore structure with two-dimensional MFI molecular sieve, parallel to the a axis of the ten membered ring is in a S shape, aperture of 0.51nm * 0.55nm, ten membered ring and linearly parallel to the b axis direction,aperture of 0.54nm * 0.56nm.

Use

Ammoxidation catalyst is produced by our company, the averagediameter of 50-60m, minimum close to 10m, the maximum is less than 105m, uniform particle size distribution.

Ammoxidation catalyst can be used as catalytic oxidation catalyst,is widely used in oxidation, epoxidation and amidoximation reaction.For example, a catalyst for the production of propylene oxide,catalyst for the production of cyclohexanone oxime.

Ammoxidationcatalyst TS-1 titanium silicon molecular sieve

Index | Unit | Figure | ||

Index of single digit (SiO2/TiO2) | The molar ratio | 25-40 | ||

The sodium content of | Wt% | 0.01% | ||

The grain size of | um | 0.2-0.4 | ||

Bulk Density | g/ml | 0.55±0.1 | ||

specific surface area g | m2/g | ≥450 | ||

Water content | Wt% | < 2% | ||

Packing | Bag/drum | 25kg | ||

The reaction performance of amine oxime | ||||

Raw material conversion rate (%) | ≥99.9% | |||

The epoxidation reaction performance(%) | ≥99% | |||

The one-way service life | ≥240hour | |||

The total life | ≥3000hour | |||

The properties of epoxy reaction | ||||

The epoxidation reaction performance(%) | ≥99.9% | |||

Product selectivity (%) | ≥95% | |||

Life | ≥400hour | |||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T,Western Union | Shipping time | Negotiable |

- President

- Hao Shu hong

- Address

- No.108 Industrial Road, hi-tech Development Zone, Zibo, Shandong, China

- Product Category

- Catalyst & Chemical Auxiliaries

- Year Established

- 2004

- No. of Total Employees

- 101-500

- Company introduction

-

Zibo Hengyi Chemical Co., Ltd., located in Zibo high tech Development Zone, where a prosperous economy, excellent geographical environment, Jinan Qingdao highway and Jiaoji Railway in this intersection, traffic is convenient.

The company has strong technical strength, well-equipped, advanced technology, quality management standards, with Tianjin University, Shandong University of Technology, Tianjin Chemical Engineering Research and Design Institute, Research Institute of petroleum and petrochemical, Shanghai Petrochemical Research Institute, Lanzhou, Qilu Petrochemical Research Institute and other experts as the backing, have certain research and development capabilities. The main products for TS-1,Hydration catalyst ,Activated Alumina oxydol adsorbent, sulfur recovery catalyst, petroleum chemical industry with a desiccant, polyethylene deliming agent, catalyst carrier multi-purposeand hydrogenation catalyst. The product is stable, the production indexes accord with nationalindustry standards. Among them, the polyethylene deliming agent and hydrogen peroxidefluidized bed process special adsorbent is currently the only manufacturer. The stability of product quality and perfect after sale service at home and abroad have been recognized by customers and praise.

Our annual production capacity of 26000 tons,Hydration catalyst 400tons,TS-1 200tons Through the ISO9001 certification, the company contracts, keeping promises, adhere to the quality of survival, relying on technology and development. We warmly welcome customers at home and abroad to visit our company, warmly welcome the relevant experts to my company guidance, and seek common development.

- Main Markets

-

China

China

India

India

Japan

Japan

Kazakhstan

Kazakhstan

South Korea

South Korea

Viet Nam

Viet Nam

- Main Product

Related Products

Calcium Lactate

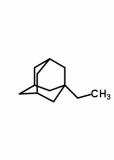

1-ethyltricyclo[3.3.1.1~3,7~]decane, CAS NO.: 770-69-4

Citric Acid Monohydrate

Prevention of Infectious Diseases (Doctor-Q)

sodium hyaluronate