WBP Waterproof Formwork For Construction

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- XINFUSHI WOOD

- Payment Terms

- L/C,Others,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Timber

Shouguang Fushiwood Group

- Verified Certificate

-

9

| Product name | WBP Waterproof Formwork For Construction | Certification | - |

|---|---|---|---|

| Category | Timber | Ingredients | - |

| Keyword | film faced board , film face plywood , 18mm film faced plywood | Unit Size | 1220.0 * 18.0 * 2440.0 mm |

| Brand name | XINFUSHI WOOD | Unit Weigh | 30 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | 440810 |

Product Information

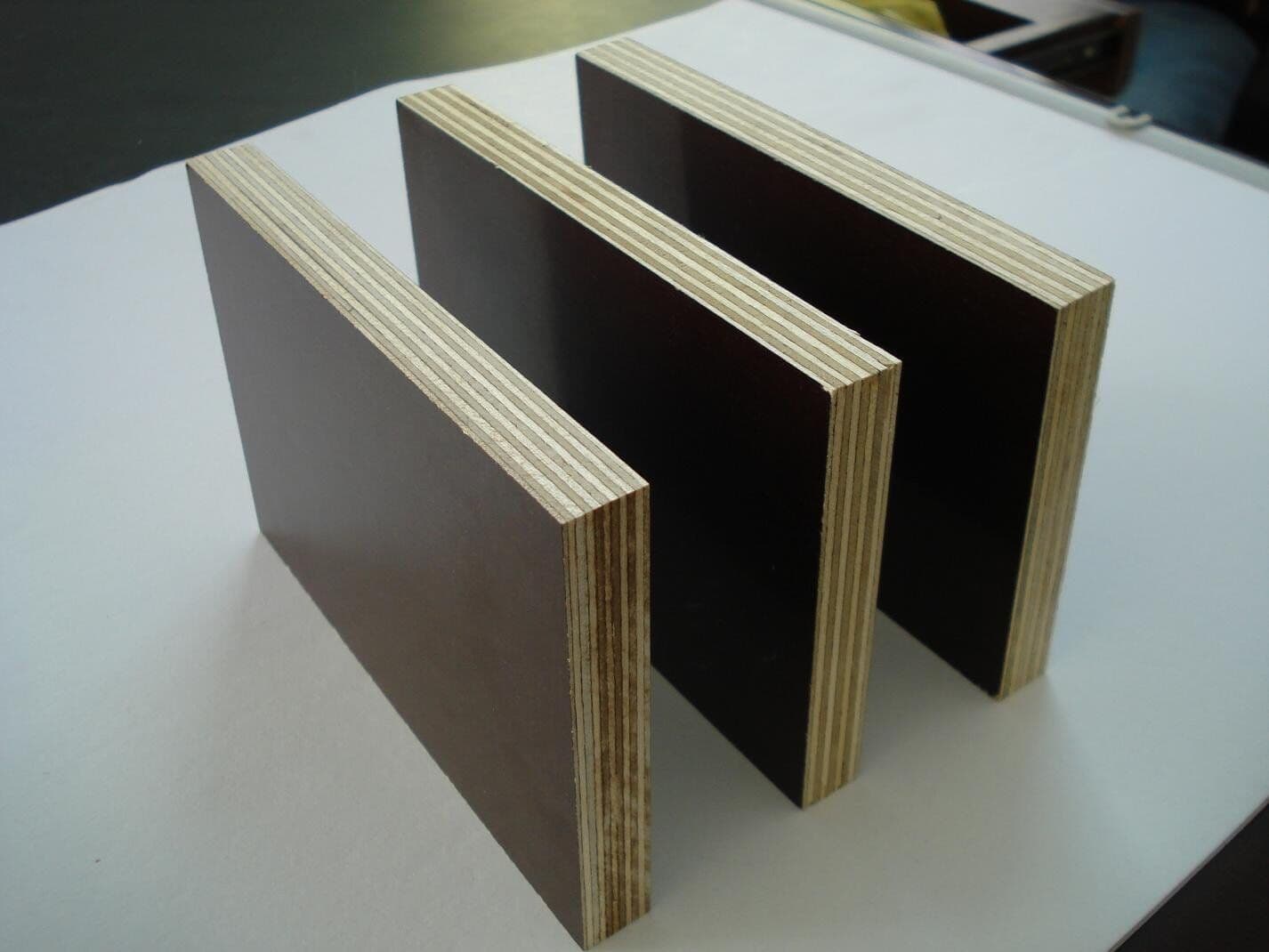

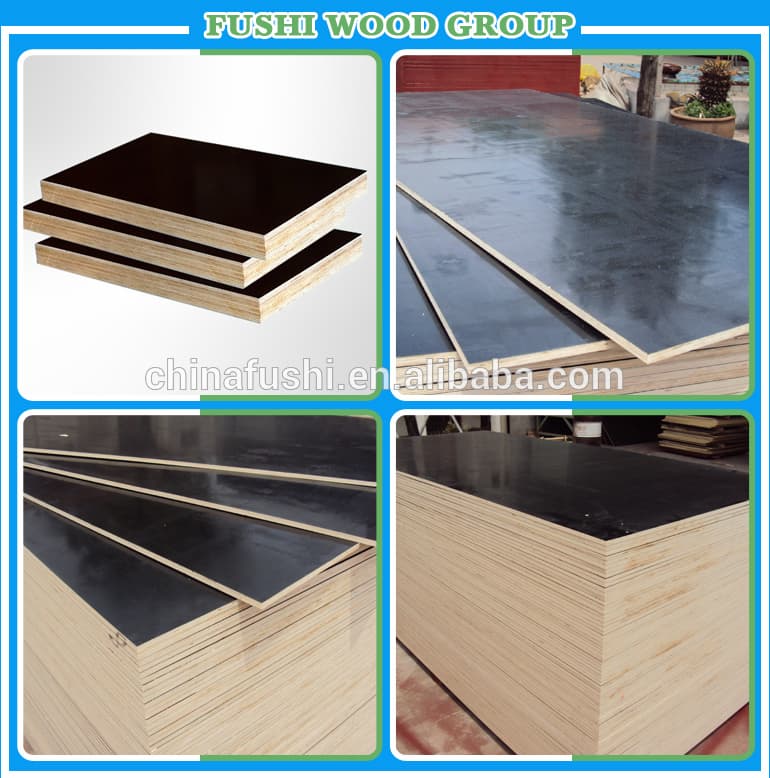

High Quality WBP Glue Waterproof Formwork For Outdoor Construction

1.Formwork Description

1) Size : 1220*2440mm , 1250*2500mm or as per your request.

2) Thickness : 9-25mm

3) Core : hardwood , poplar , combi , birch etc...

4) Face / back : black , brown , or with letter

5) Glue : MR / WBP / MELAMINE

6) Usage : construction formwork

7) Density : 500-600kgs/m3

8) Used times : more than 10 times

9) Certification : CARB , CE , ISO9001:2008

10) MC : below 14%

11) Formaldehyde emission standards : E0 /E1 / E2

2. Features & Advantages

1) flexible , inexpensive , workable and re-usable

2) resistance to cracking , shrinkage , splitting , and twisting/warping , used instead of plain wood

3) high degree of strength and very hard to bend

3.Trade Terms

1) Packing : warpped with 0.2mm plastic bag inside , pallets packing,strengthened by iron belt .

2) Quantity : 20GP : 8pallets / 21CBM 40HQ : 18pallets / 50CBM

3) Delivery time : in 15 days after T/T with 30% deposit or L/C at sight

4) Payment : T/T with 30% deposit or L/C at sight

ABOUT OUR COMPANY:

1) 30 years plywood production experience.

2) 12 production lines.

3) Daily output 10x40HQ.

4) Anuual export: 200 million USD or so.

5) Delivery Time: Within 7 days after 30% deposit

BUYER TIPS:

FAQ:

1. How to choose plywood?

1) To choose proper wood species, patterns and colors according to usage and

Personal preferences; Appearance quality of plywood directly affects the effects in

Use; Face of plywood should have damages, bumps, rot, knots, cracks, indentation,

Dirt, rough and other defects; Requirements for back of plywood is generally less

Strict.

2) To choose the plywood that its layers of veneer are spliced tightly, no stack or noopen joint.

3)To choose environmentally friendly plywood. Do not buy the plywood with clearpungent odor.

2. Why does the plywood warp?

Is due to large internal stress within plywood. The reason is that the moisture content of face and back veneer is inconsistent with each other: Different species veneer mismatches unreasoningly; Veneer texture distortion; Individual hot pressure temperature is not enough; Plate piled unevenl

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- fushi street 2399 shouguang

- Address

- Fushi street ,Shouguagn city China

- Product Category

- Other Constructions

- Year Established

- 1987

- No. of Total Employees

- over 2000

- Company introduction

-

In 1987, Fushi Wood Group was founded as supplier for world leading furniture company Ashley. In 2001, the group produced the first ... MoreIn 1987, Fushi Wood Group was founded as supplier for world leading furniture company Ashley. In 2001, the group produced the first LVL (Laminated Veneer Lumber) from China, and keeps to be leading Asian LVL manufacturer in accordance with OSHA, AUS 1577 and EN 13377.Now, the group has over 2300 employees and 10 factories in Shandong Province of China, properties covering land 466,200 square meters, business scope successfully involved in real estate, plank, furniture and chemistry. Plank business involved in LVL , Plywood, H20, MDF, PB & OSB with production capability yearly over 300,000 cubic meters which are certified by ISO 9000, ISO14001, SONCAP, CARB of U.S and CE of Europe..Products safety and quality are central to our brand equity and are the reason partners and clients trust us. The mission of Fushi Wood Group is to ensure, through quality planning and execution, that all Fushi products deliver the desired consumer experience and occupational safety. Our global quality assurance approach is a collaborative effort between quality professionals in our corporate offices, as well as on the ground around the world in the markets where we do business.We are committed to learning and continuous improvement. We will continue to seek out and implement best practices in quality management to be worthy of the trust our consumers.Less

- Main Markets

-

Algeria

Algeria

China

China

Japan

Japan

Singapore

Singapore

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

LVT - Loose Lay, PVC Flooring, Vinyl Tile

ACACIA FINGER JOINT

Plywood 4x8 feet size, thickness 7mm grade BC

Korea MDF

PVC Tile - Wood Plank