SAOSA UV Curing cast in place resin for glass lamination

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- SAOSA

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Coating & Paint

SAOSA UV curing resin for glass lamination

- Verified Certificate

-

8

| Product name | SAOSA UV Curing cast in place resin for glass lamination | Certification | - |

|---|---|---|---|

| Category | Coating & Paint | Ingredients | - |

| Keyword | acrylic resin , one component , uv curing resin , led laminated resin | Unit Size | 30.0 * 30.0 * 40.0 cm |

| Brand name | SAOSA | Unit Weigh | 25 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

SAOSA UV curing resin

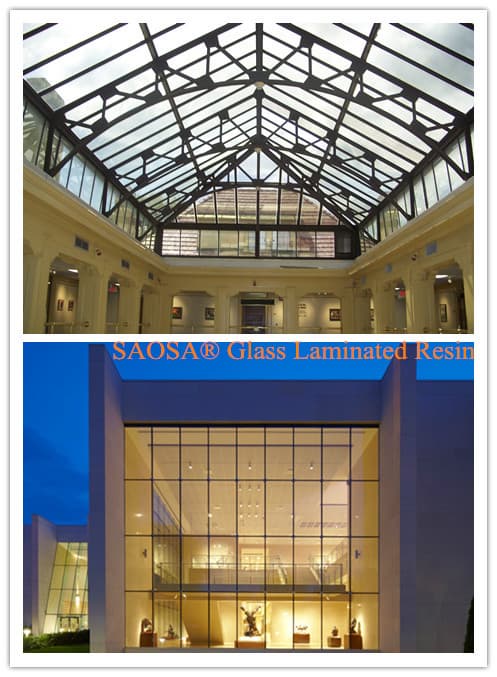

Quality laminated glass interlayer

1. What is laminated glass?

Laminated glass has the advantage over standard glass in that it will not shatter as the polymeric interlayer is not subject to brittle failure as is the glass. Furthermore, the interlayer provides a barrier against penetration, while the polymeric material also acts as a sound deadening layer.

2. Laminated glass manufacturing processes

There are three different laminated glass manufacturing processes:

1) The first method utilizes two or more pieces of glass bonded between one or more pieces of plasticized polyvinyl butyric (PVB) resin using heat and pressure.

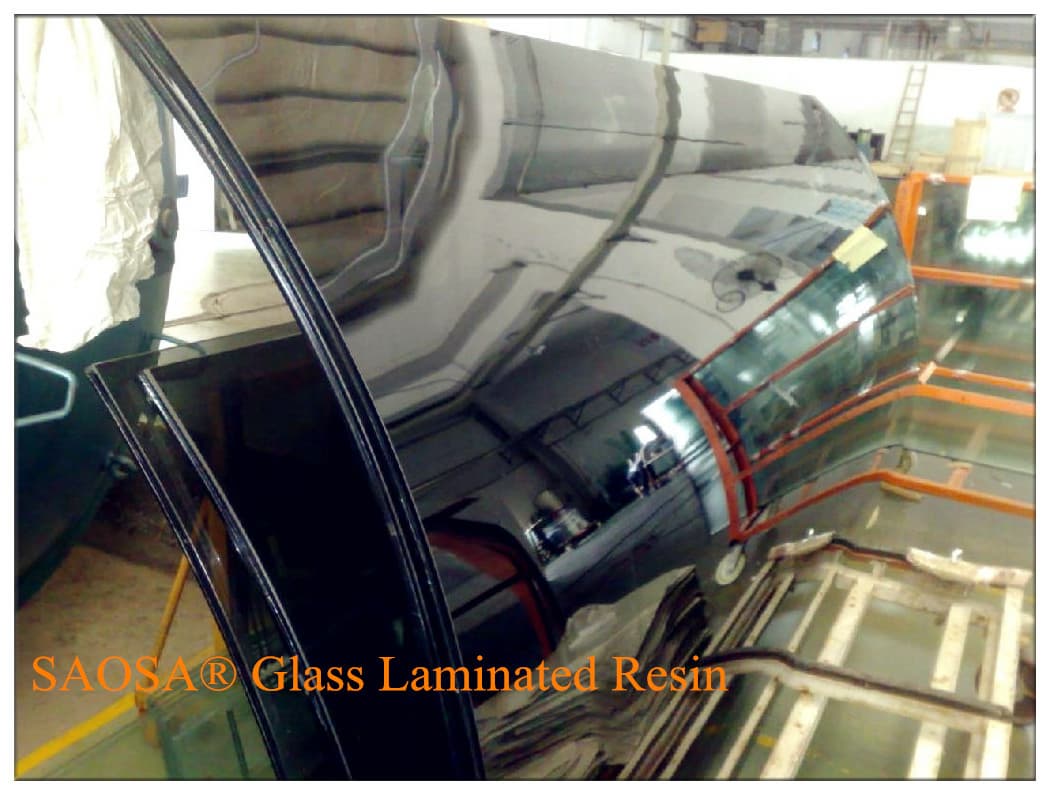

2) The second method is manufactured by pouring resin into the cavity between two sheets of glass which are held together until the resin cures.

3) The third method uses two or more pieces of glass and polycarbonate, bonded together with Ethylene Vinyl Acetate (EVA) interlayers under heat and pressure.

3. Resin laminated process advantage

The resin laminating process is recognized as one of the most advanced, user-friendly and energy efficient methods of producing laminated glass in the world. Why?

First, no big machineries and no electric bills in resin laminating production. Compared to PVB, frequently used in processing laminated glass, no autoclave with high temperature and high pressure is required in using our resin. Very low investment costs and low energy consumption are involved. Only workers and material can finish the whole laminating work.

Secondly, it is very easy to use.

1) Our UV curing resin is PVB liquid, one-component, ready-to-use casting resin for glass lamination. Its light transmittance is higher than glass's, not be yellowing with age and it performs well in adhesive strength, resisting 100° above and -40° below.

2) As the resin is liquid, it perfectly fills the space between the glass sheets, whether these are of an irregular surface or whether they are formed or cured glass shapes.

3) Curing is by UV light or Sun's rays, which just requires about 30-50 minutes in exposing to UV for curing. The material contains no solvent nor plasticizers (SGS certificated) and no water evaporated.

4. SAOSA UV curing resin

SAOSA is the ONLY resin brand in Asia that has passed Europe Standard with certificates and test reports, such as EN 356, EN 12543-4, EN 12600, EN 1063 and so on. Our resin laminated glass has been proved 10 years no yellowing, no delamination and no bubbles. We has served over 80 countries and over 2000 glass fabrication factories all over the world for past 20 years. We could offer you one component, acrylic liquid, UV curing resin below:

SaoSA UV-S is for general laminated glass, with strength of high transparency rate

SaoSA UV-H is for architectural laminated glass, with strength of high impact resistance.

SaoSA UV-B is specialized for bulletproof laminated glass.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Nina chi

- Address

- xiamen,fujian, China

- Product Category

- Coating & Paint

- Year Established

- 1998

- No. of Total Employees

- 51-100

- Company introduction

-

SAOSA UV curing resin is exclusively for glass lamination, which is mostly used in laminated safety and security glass. It has been proved as a qualified interlayer material of laminated glass by thousands of customer for past twenty years.SAOSA Technology International Ltd. has been devoted to researching and manufacturing glass lamination resin for tens of years. As the largest manufacturer of glass lamination resin in China, we have a strong confidence in providing the resin with good quality and competitive cost to our customers all over the world. Before launching in civil market, SaoSA resin is the unique material adopted by China military party, applied to laminated glass of security constructions. With the experience of cooperating with military party, SaoSA inherits military standard to develop products, supervise production and control the quality.

- Main Markets

-

U. Kingdom

U. Kingdom

U.S.A

U.S.A

Ukraine

Ukraine

- Main Product

China

China