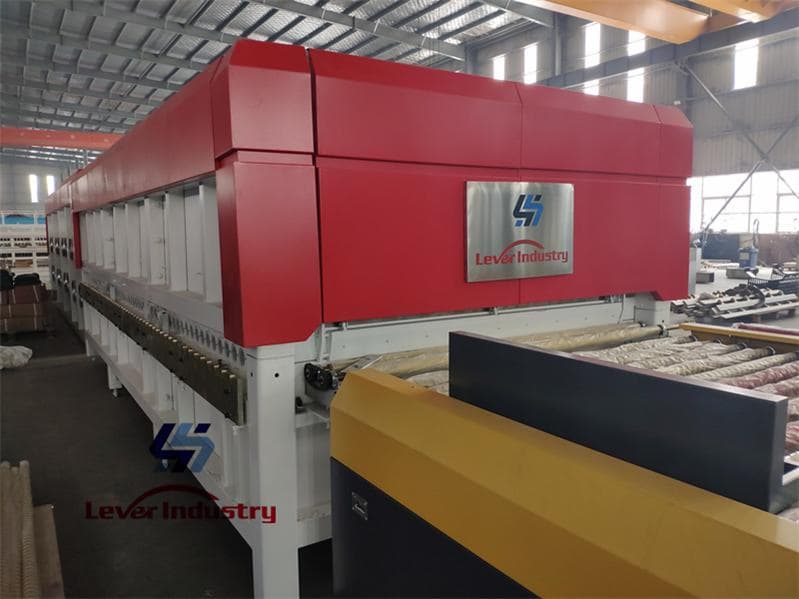

Horizontal Rollers Hearth Glass Tempering furnace

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- LEVER

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Glass Production Machinery

LUOYANG LEVER INDUSTRY CO.,LTD

- Verified Certificate

-

8

| Product name | Horizontal Rollers Hearth Glass Tempering furnace | Certification | - |

|---|---|---|---|

| Category | Glass Production Machinery | Ingredients | - |

| Keyword | tempered glass , glass tempering furnace , glass oven , glass toughning machine | Unit Size | - |

| Brand name | LEVER | Unit Weigh | 20000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | 8475 |

Product Information

Flat Glass Tempering Furnace / Glass Toughening Plant

1. Machine Application

For processing flat tempered glass and thermal strengthened glass, which mainly used in the fields of Building glass, household glass, shower room glass, etc.

Popular glass size (as max. flat glass size)

800x1200mm | 1700x3000mm | 2200x4200mm | 3000x4200mm |

1220x2500mm | 1700x4200mm | 2440x3660mm | 3000x5000mm |

1220x3660mm | 1800x3000mm | 2440x4200mm | 3000x6000mm |

1300x2500mm | 1800x4200mm | 2440x5000mm | 3000x8000mm |

1500x2500mm | 2000x3660mm | 2440x6000mm | 3300x4200mm |

1500x3660mm | 2000x5000mm | 2440x8000mm | 3300x6000mm |

1. This machine is used to produce the flat & bent tempered glass. The processed glass can be used for buildings, shower room, sidelite of car or bus, etc.

2.The machine adopts industrial control computer and PLC, the speed can be adjusted by the inverter steplessly. High automation made it reliable and precise, easy to operate and efficiency.

3.Conveying speed of the glass entering and exiting the heating oven is controlled by inverter, which can assure high synchronization and avoid scratch on the glass.

4.Heating section has a helix matrix structure, which can control the temperature independently. Reasonable design and unique structure of heating elements make a long serve life.

5. The heating oven body is full closed and the Insulating materials are of high quality material with top performance which can ensure a lower energy consumption.

6. The emergency cooling system is greatly convenient for machine maintenance.

7. The proportion of the air pressure between the upper quench and the lower quench can be adjusted.

8. The operaton for bending forming is easy and the forming precision is very high, also, it is very easy to change the glass type during production.

9. The software has a powerful function, which is very convenient for operation, maintenance and adjustment.

10. The whole production procedure is controlled and monitored by computer, which is of high automation.

Optional Information

Horizontal Rollers Hearth Glass Tempering Furnace

1. Machine Application

For processing flat tempered glass and thermal strengthened glass, which mainly used in the fields of Building glass, household glass, shower room glass, etc.

Popular glass size (as max. flat glass size)

800x1200mm | 1700x3000mm | 2200x4200mm | 3000x4200mm |

1220x2500mm | 1700x4200mm | 2440x3660mm | 3000x5000mm |

1220x3660mm | 1800x3000mm | 2440x4200mm | 3000x6000mm |

1300x2500mm | 1800x4200mm | 2440x5000mm | 3000x8000mm |

1500x2500mm | 2000x3660mm | 2440x6000mm | 3300x4200mm |

1500x3660mm | 2000x5000mm | 2440x8000mm | 3300x6000mm |

1. This machine is used to produce the flat & bent tempered glass. The processed glass can be used for buildings, shower room, sidelite of car or bus, etc.

2.The machine adopts industrial control computer and PLC, the speed can be adjusted by the inverter steplessly. High automation made it reliable and precise, easy to operate and efficiency.

3.Conveying speed of the glass entering and exiting the heating oven is controlled by inverter, which can assure high synchronization and avoid scratch on the glass.

4.Heating section has a helix matrix structure, which can control the temperature independently. Reasonable design and unique structure of heating elements make a long serve life.

5. The heating oven body is full closed and the Insulating materials are of high quality material with top performance which can ensure a lower energy consumption.

6. The emergency cooling system is greatly convenient for machine maintenance.

7. The proportion of the air pressure between the upper quench and the lower quench can be adjusted.

8. The operaton for bending forming is easy and the forming precision is very high, also, it is very easy to change the glass type during production.

9. The software has a powerful function, which is very convenient for operation, maintenance and adjustment.

10. The whole production procedure is controlled and monitored by computer, which is of high automation.

Optional Information

Horizontal Rollers Hearth Glass Tempering Furnace

1. Machine Application

For processing flat tempered glass and thermal strengthened glass, which mainly used in the fields of Building glass, household glass, shower room glass, etc.

Popular glass size (as max. flat glass size)

800x1200mm | 1700x3000mm | 2200x4200mm | 3000x4200mm |

1220x2500mm | 1700x4200mm | 2440x3660mm | 3000x5000mm |

1220x3660mm | 1800x3000mm | 2440x4200mm | 3000x6000mm |

1300x2500mm | 1800x4200mm | 2440x5000mm | 3000x8000mm |

1500x2500mm | 2000x3660mm | 2440x6000mm | 3300x4200mm |

1500x3660mm | 2000x5000mm | 2440x8000mm | 3300x6000mm |

1. This machine is used to produce the flat & bent tempered glass. The processed glass can be used for buildings, shower room, sidelite of car or bus, etc.

2.The machine adopts industrial control computer and PLC, the speed can be adjusted by the inverter steplessly. High automation made it reliable and precise, easy to operate and efficiency.

3.Conveying speed of the glass entering and exiting the heating oven is controlled by inverter, which can assure high synchronization and avoid scratch on the glass.

4.Heating section has a helix matrix structure, which can control the temperature independently. Reasonable design and unique structure of heating elements make a long serve life.

5. The heating oven body is full closed and the Insulating materials are of high quality material with top performance which can ensure a lower energy consumption.

6. The emergency cooling system is greatly convenient for machine maintenance.

7. The proportion of the air pressure between the upper quench and the lower quench can be adjusted.

8. The operaton for bending forming is easy and the forming precision is very high, also, it is very easy to change the glass type during production.

9. The software has a powerful function, which is very convenient for operation, maintenance and adjustment.

10. The whole production procedure is controlled and monitored by computer, which is of high automation.

Optional Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- LEE

- Address

- NO.99,JIN'GU'YUAN ROAD,LUOYANG

- Product Category

- Glass Production Machinery

- Year Established

- 2010

- No. of Total Employees

- 101-500

- Company introduction

-

Lever Industry, offers not only the heat treatment preprocessing machinery, but also the glass processing industry. You could choose a single machine or an entire solution, or the upgrades improvements on your current machine. The reasonable technicalcommercial structure ensures the high efficiency and professional competence in each stage of the clientsupplier business relations.

Lever Industry has established the entire series of technical solutions for the flat and bent tempered glass products to meet the demands in architectures, automotive, furniture, household appliances, automobiles and solar energy industries, especially, we could offer the most advanced complete automotive glass production line and highest automation flat glass laminating line.

We are mainly specialized in Glass Tempering furnace,& Glass Laminating Line for many years with BEST quality & BEST rate:

1. Flat Glass Tempering Furnace ,

2. Single Bent Glass Tempering Furnace ,

3. Flat & Bent Combination Glass Tempering Furnace in one machine,

4. Double Curvature Bent Glass Tempering Furnace (For rear glass of automobile),

5. Single Bent & Double Curvature Temepering furnace,

6. Continuous Flat Glass Tempering Furnace,

7. Continuous Bent Glass Tempering Furnace,

8. Flat Glass Laminating Line,

9. Bent Glass Laminating Line (For windshields of car or bus),

- Main Markets

-

Bangladesh

Bangladesh

China

China

Hong Kong(China)

Hong Kong(China)

India

India

Indonesia

Indonesia

Pakistan

Pakistan

Philippines

Philippines

South Korea

South Korea

U.S.A

U.S.A

Viet Nam

Viet Nam

- Factory Information

-

workshop 1

- Main Product

Related Products

Wash Machine Shaft spider 5kg

Horizontal Glass Washing and Drying Machine

Insulating Glass Production Line/Double Glazing Glass Machine/Glass Processing Machine

Sputtering System - In-Line Coating System

Precision Glass cleaning and conveying PVA sponge rollers