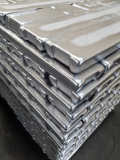

Calcium Removal ZS-ACC

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- LANDE

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- calcium removal, removal zs-acc

- Category

- Aluminum Alloy & Profiles

SICHUAN LANDE INDUSTY COMPANY LTD

- Verified Certificate

-

9

| Product name | Calcium Removal ZS-ACC | Certification | - |

|---|---|---|---|

| Category | Aluminum Alloy & Profiles | Ingredients | - |

| Keyword | calcium removal , removal zs-acc | Unit Size | - |

| Brand name | LANDE | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Yuanye

- Address

- 99# Longhu Ave, Eastern Industrial Zone, Xindu District, Chengdu, P.R. China

- Product Category

- Aluminum Alloy & Profiles

- Year Established

- 1993

- No. of Total Employees

- 101-500

- Company introduction

-

SICHUAN LANDE INDUSTRY COMPANY LTD., founded in 1993, specializing in the production of aluminum melt materials enterprises, focus on non-ferrous metals in more than 20 years of melt materials research and development, production and sales, one of several big brand suppliers for domestic recognized, users for aluminum sheet, belt, foil, cable and aluminum ingots, aluminum castings, aluminum processing enterprises.

Mother products among aluminum base alloy (alloy), element additives and three categories of flux, used in non-ferrous metal smelting casting process, its effect is melt purification (refining slag, degassing), the composition adjustment and casting crystallization (refinement, metamorphic) control of the organization, so as to significantly improve the quality of aluminous material performance and metallurgy.

- Main Product

Related Products

HF High Frequency Welded Auto Intercooler Aluminum Tube

Scrap Transformer CRGO silicon steel

Aluminum Ingot

Aluminium Zirconium master alloy

aluminium windows profiles

China

China