Acrylic emulsion for sound deandener

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- APOND

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

APEC, Ltd.

- Verified Certificate

-

14

| Product name | Acrylic emulsion for sound deandener | Certification | - |

|---|---|---|---|

| Category | Adhesive & Sealants for Transportation | Ingredients | - |

| Keyword | acrylic emulsion for liquid applied sound deadener , water based acrylic emulsion for vibration adsorption , liquid applied sound deadener , sound deadener | Unit Size | - |

| Brand name | APOND | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 3906909000 |

Product Information

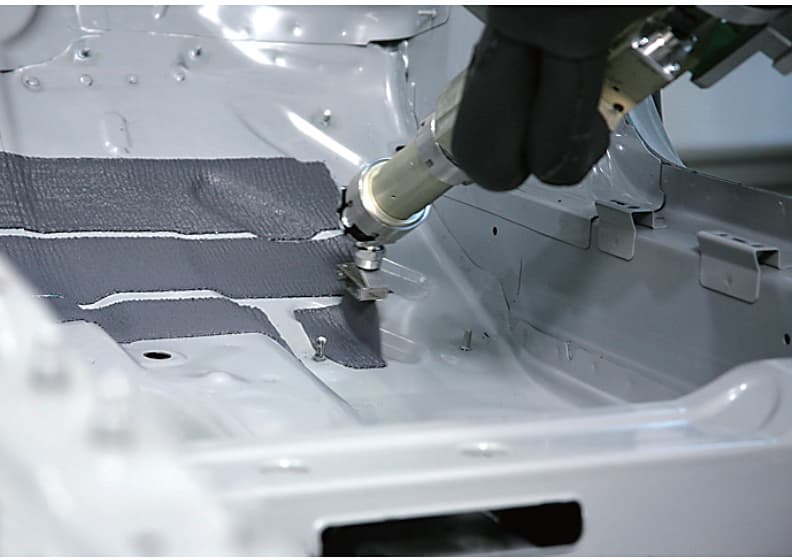

As vehicle manufacturers(VMs) strive to lower manufacturing costs and simultaneously reduce weight, increase performance, and use environmentally friendly materials, a new generation of low VOC coatings has been developed and used for various applications in auto factories' body and paint shops. One of these 'green' technologies focuses on the sound damping of vehicle body structures to reduce noise in the passenger compartment.

APEC's tailor-made, high-quality water-based pure acrylic polymer emulsion, APOND® AP-4679, that was specifically developed for this application helps formulate highly efficient aqueous sound damping masses. water-based LASD (Liquid-Applied Sound Deadener) is a bakeable thick-film coating that is designed to replace melt-on (heat-fusible), manually-applied asphalt damping pads used on various areas of a vehicle's body structure – namely floor pans, tunnel, dash panel, inner door skins, roof panel, and trunk floor – to damp sheet metal resonance, allowing for automated, robotic application. This reduces labor costs, process variation, and multiple inventory part numbers, as associated with asphalt pads. Robotic application enables VMs to obtain optimal geometry, location, and thickness of the coating, even as running changes are made.

| Product name | Applications | Key properties | Solid (%) | pH (25℃) | Viscosity (cps, 25℃) | Tg (℃) | Ionic charge |

| Applications for LASD (liquid-applied sound deadener) for automotive floor (Acrylic emulsions) | |||||||

| APOND® AP-4679 | sound deadener for automotive floor | excellent workability, flexibility, water resistance, milky-white liquid | 50.0 ~ 52.0 | 7.8 ~ 8.4 | 1,000 ~ 3,000 | -15 | anion |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Myungsik Shim

- Address

- 18, 230 Beon-Gil, Manhae-Ro, Danwon-Gu, Ansan-Si, Gyeonggi-Do, Republic of Korea

- Product Category

- Other Adhesives & Sealants

- Year Established

- 1996

- No. of Total Employees

- 1-50

- Company introduction

-

<p>

APEC, established in 1996, specializes in R&D and manufacture of environment-friendly waterborne acrylic emulsion adhesives and PSA (Pressure Sensitive Adhesives)m and waterborne PUD & AUD. With its mission to contribute to human health and natural environment conservation by endeavoring to convert solvent-based emulsion adhesives into water-based ones, APEC has been committed to creating customer value and grown with its customers by collaborated, intensive R&D activities for the last two decades.

Our capacity for agile renewal coupled with innovative corporate culture and supportive leadership enables us to offer our customers tailor-made, environment-friendly products that help them meet their local and global standards and responsibilities with high performance products.

Our technological capabilities meet increasing customer demand for high quality and sustainable options. We collaborate and partner with you to understand your needs and recommend the right solutions.

- Main Product

Related Products

FLOATING SEAL

what adhesive is better for conveyor belt bonding_

Micro adhesive

Solvent based OEM PVC pipe glue

Industrial gelatin 15-280bloom,bone glue ,hide glue

South Korea

South Korea