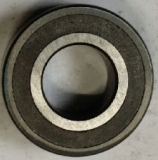

wire straightening roller bearing A1002ZZ (10mmx35mmx9mm )

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- MOTN

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- wire straightening roller bearing a1002zz, v groove ball bearing a1002zz, stainless steel track roller ball bearings a1002zz, linear motion guide roller bearing a1002zz

- Category

- Ball Bearings

Motion(Shanghai) Industrial Development Co LTd

- Verified Certificate

-

10

| Product name | wire straightening roller bearing A1002ZZ (10mmx35mmx9mm ) | Certification | - |

|---|---|---|---|

| Category | Ball Bearings | Ingredients | - |

| Keyword | wire straightening roller bearing a1002zz , v groove ball bearing a1002zz , stainless steel track roller ball bearings a1002zz , linear motion guide roller bearing a1002zz | Unit Size | 10.0 * 35.0 * 9.0 mm |

| Brand name | MOTN | Unit Weigh | 0 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

| Name: | Wire Guides and

Straightening Roller bearings thread guides and straightening rollers |

| Model Numbe | A1002ZZ;A1002 2RS |

| Dimension: | 10mmx35mmx9mm |

| Structures | Single row V groove ball bearings |

| Groove Angle | 90 degrees |

| Material: | Chrome Steel /GCr15/ AISI420/AISI440 |

| Quality: | ABEC1 ABEC3 |

| Vibration Level: | V1;V2 |

| Noise Level: | Z1;Z2 |

| Clearance: | C0 C3 C2 C5 |

| Shields: | Rubber seals ; Steel Shield |

| Packing: | Plastic Tube packing |

| Brand: | MOTN |

| Payment term: | T/T, L/C; West Union |

| Market: | Europe 70%; Asia 20%; Other Market 10% |

| Delivery time: | 30 days |

| Origin: | JIangsu Province |

| Descpritions | The

straightening of cables, strips and wires is performed in steps with

successive stages until the final product is obtained. To rationalize the

handling between the different steps the material is stocked on reels or on

bobbins and takes forms which are not natural. For every production step, it is therefore necessary to carry out the inverse process by taking the material off its support. At that moment, the straightening operation takes place. It may be divided into three steps: The straightening, consisting of putting the material back into its original shape. The operation is carried out by the first straightening rollers. The removal of the residual constraint in the material, due to the winding on the bobbin. This operation is performed by the rollers located in the central part of the straightener. The forming of the wire carried out by the last rollers on the straightener, generally placed at an angle of 90°compared to the angle of the first rollers. Often it is necessary to combine these three steps. That is the reason why the straightener uses 5, 7, 9, 11 or even 13 rollers placed in two planes. The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the rectified "V" notch on the outer ring has the same geometric characteristics and precision as the rest of the bearing. For this reason, the notch on a YITONG roller is precise machined prior to bearing assembly. Grinding this notch on an assembled standard bearing is risky, as the bearing may be damaged. An acceptable uniformity and geometrical precision can thus not be guaranteed. The service life of the roller is much shorter and the quality of wire drawing suffers accordingly. Among numerous applications using thread guides and straightening rollers, |

| Application: | •

Machine tools for fiberglass cables (lawn mowers) • Machines for spring manufacturing • Machines for metal wires • Machines for spooling, un-spooling and rewinding • Fine and high precision wire drawing |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Mr.Chou

- Address

- Room 503 Building 7 No. 277 YongDeng Road Putuo District Shanghai China Postal Code 200331

- Product Category

- Ball Bearings,Needle Bearings

- Year Established

- 2006

- No. of Total Employees

- 1-50

- Company introduction

-

Motion (shanghai) Industrial development Co.Ltd ONLY focuses on Bearings and transmission products with its registered brand “MOTN”; we offer a very comprehensive and extensive range of products; all parts in the areas of bearings; power transmission; linear technology; sealing technology and technical industrial suppliers are available both as a h high-tech version or low-price brand.

we have constantly expanded our product range and today offer you numerous manufacturer independent products in the field of rolling bearing technology - from high-tech to low-price brand. We consistently focus on best quality and reliability of reputable manufacturers.

We will audit every manufacturer we are going to work with. Our manufactures are all ISO 9001 Certificated

Our Principe: Sincerity, Honesty and Responsibility to every of our client

- Main Markets

-

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Malaysia

Malaysia

Netherland

Netherland

South Korea

South Korea

Spain

Spain

- Main Product

China

China