Conveyor belt repair strip instruction for use

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Ramimtech

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- conveyor belt repair strip, cold vulcanzing repair strip, conveyor belt cold vulcanzing repair strip

- Category

- Rubber Belts

HENAN YINMEITE MACHINERY CO.,LTD

- Verified Certificate

-

11

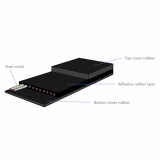

| Product name | Conveyor belt repair strip instruction for use | Certification | - |

|---|---|---|---|

| Category | Rubber Belts | Ingredients | - |

| Keyword | conveyor belt repair strip , cold vulcanzing repair strip , conveyor belt cold vulcanzing repair strip | Unit Size | - |

| Brand name | Ramimtech | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

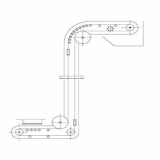

Conveyor belt repair strip instruction for use

Image1. Choosing one piece of conveyor

belt repair stirp which is 2-3mm larger than damage area. As

damage area is center, drawing out marking line.

Making preparation work for

roughening.

1.Choosing one piece of repair stirp which is 2-3mm larger than

damage area.As damage area is center, drawing out marking line.

Making

preparation work for roughening.

Images2. Roughening damage area by using of angle grinder which is with high

power and low speed and is equiped with tungsten steel grinding disc.

2.When

roughening damage area,we recommend angle grinder RAMIMTECH-L1202 which is with

high power and low speed and is equiped with tungsten steel grinding

disc.

the value of roughening depth can't be smaller than the thickness

value of repair stirp. For instance, the thickest part of 150mm fabric

reinforced repair stirp is 4.6mm, so we need roughen 4.6mm to avoid repair strip

being scraped by belt cleaner.

Image3. Using non-flammable cleaning solution to clean roughened

area.

3.Clean the roughened area by using cleaning solution SK353 and then

wait it dry.

Image4. Pouring hardener UT R40 into cold vulcanizing glue ,and stiring it

well at the same time.

4.While waiting cleaning soluiton dry, we can mix

cold vulcanizing glue with hardener UT R40 and make two components mix well.

Image5. Brushing the mixture of cold vulcanzing glue SK313 and UT R40 to the

whole surface which need repair, and waiting it dry to the degree that do not

stick finger back.

5.Brushing the mixture of cold vulcanzing glue SK313 and

UT R40 to the whole surface which need repair, and waiting it dry to the degree

that do not stick finger back.Be sure to brush evenly at the same thickness on

the whole surface.

Image6. Brushing mixture of cold vulcanizing glue SK313 and UT R40 onto the

blue bonding layer of repair strip and wait it dry to the degree that it is

slightly stick.

6.Brushing mixture of cold vulcanizing glue SK313 and UT R40

onto the blue bonding layer of repair strip and wait it dry to the degree that

it is slightly stick.

Image7. When bonding RIT conveyor belt cold vulcanizing repair

strip onto belt,use roller stitcher to roll the surface

firmly.

7.When bonding RIT repair strip onto belt,use roller stitcher to roll

the surface firmly.

Image8.After bonding,need brush one coat mixture glue at the bonding edge of

repair strip and conveyor belt , and make the edged CN layer of repair strip

have cold vulcanizing reaction by itself.

8.After bonding,need brush one

coat mixture glue at the bonding edge of repair strip and conveyor belt , and

make the edged CN layer of repair strip have cold vulcanizing reaction by

itself.

Image9. If damage need a few of repair strips, look out the lap way. we can

operate as image showed.

9.If damage need a few of repair strips, look out

the lap way. we can operate as image showed.

Special operation pionits of conveyor belt repair

strip.

1.Ramimtech materials must be stored at cool dry ventilated

place.

2.Temperation of loading material on conveyor belt under 90

℃.

3.Please use repair materials with non-flammble lable when do underground

repair.

4.Bond repair stirp and repair patch in embedded way to avoid of

being scraped by belt cleaner.

5.If the surface for bonding is damp,must make

it dry before bonding.

6.Do not burn the surface when roughening,abrasion

wheel is not allowed to use,only can use RIT tungsten carbide buffing

disc.

7.Use steel brush to clear off dust and rubber scraps,and use RAMIMTECH

cleaning solution to clean the surface.

8.Glue mixture:when do seamless

jointing and repair of belt ,Ramimtech cold vulcanizing glue Sk313 need to be

mixed with hardener by the ratio of 100:4, and be stired evenly.

9.Ramimtech

mixtrue must be brushed by mane brush hard and evenly to make SK313 mixture can

be infiltrated into rubber surface.

Belt surface need brush two coats Sk313

mixture while the blue CN layer of repair strip be brushed one coat.

All the

coats need keep from dust and damp.

10.The drying time of cold vulcanizing

glue SK313 mixture depend on air temperature, humidity and absorbent of conveyor

belt itself.

The first coat on belt need dry to degree of do not stick finger

back and the second to the degree of slightly stick.

While brushing the

second coat on belt ,need brush one coat onto CN bonding layer of repair strip

at the same time.

11.Ensure both bonding surface are dry and

clean.

12.Rolling must be started from center to edge. when the first rolling

fix position of repair strip, roll second time to extrude air and make bonding

firm.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Alick Gao

- Address

- No. 88, 17th Floor, Unit 1, 3th Building, No. 66, Tongtai Road, Zhengzhou, Henan, China (Mainland)

- Product Category

- Other Rubber Products

- Year Established

- 2000

- No. of Total Employees

- 1-50

- Company introduction

-

Henan Yinmeite Machinery Co.,Ltd., which is professional manufacturer & supplier of conveyor belt cold bond splicing and hot splicing materials. We are specializing, focusing and concentrating on conveyor belt maintenance.People-oriented, strengthening management, expanding the market and creating superior service are our concept of development. Holding the concept, we built our RAMIMTECH brand and provide comprehensive service for industrial and mining enterprises.

- Main Markets

-

China

China

- Main Product

Related Products

Corrugated sidewall conveyor belt

Steel cord conveyor belt

General Rubber Sheet

Bucket elevator belt

EPDM rubber seal strip