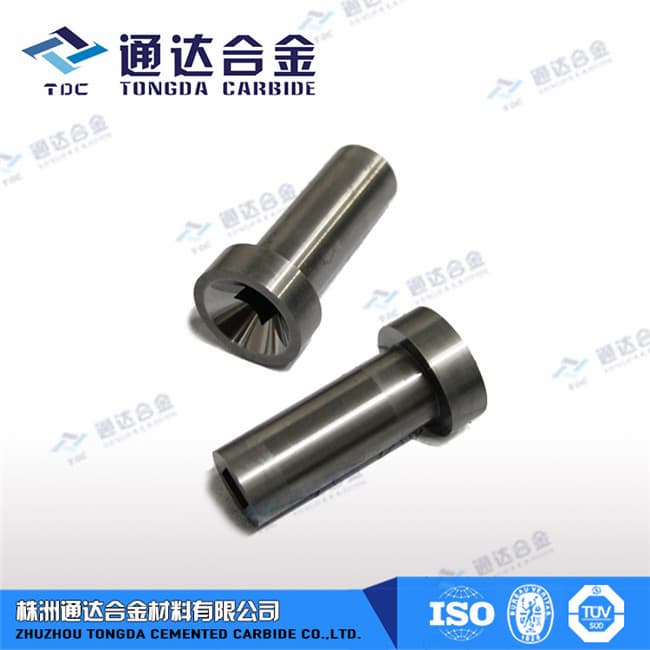

Tungsten Carbide Drawing Dies

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Drawing Dies | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | drawing dies , carbide drawing dies , tungsten carbide drawing dies | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

With the rapid development of China's industrial production, the quantity and quality of the wire made increasing demands. Wire drawing die is a key tool to make wire. Its level of quality directly affect steel quality, die losses, energy consumption and products of economic benefits. Tungsten carbide wire drawing dies are made of cemented carbide. Tungsten carbide cobalt alloy belong, whose main component is tungsten carbide and cobalt. Tungsten carbide is an alloy of the "skeleton", the main role played hard wear; Cobalt is bonded metal, is the source of the alloy toughness. Therefore, tungsten carbide wire drawing dies and alloy die compared with the following characteristics: high abrasion resistance, polishing, good adhesion of small, low friction, low energy consumption, high corrosion resistance, these features make the tungsten carbide wire drawing dies have a wide range of processing adaptability, become the most widely used wire drawing die.

Tungsten carbide wire drawing dies are made by the die core and die sets two parts, tungsten carbide wire drawing dies die core usually select tungsten carbide cobalt.

1. YG3X (WC: 97%, Co: 3%):it is a tungsten-cobalt alloy which has a lowest strength, maximum hardness, wear the best, but the toughness of the worst. Hardness is not less than 92HRC, appropriate specifications do pull thin wire (0.6mm or less optimal) diameter of 20mm non-ferrous metal and alloy wire drawing dies.

2. YG3 (C: 97%, Co: 3%): its hardness and wear resistance is slightly inferior to YC3X, but the toughness is slightly higher. Hardness is not less than 91HRC specifications suitable to do the fine wire (1.6mm or less is best) and non-ferrous metals, alloy wire drawing dies.

3. YG6 (C: 94%, Co: 6%): high wear resistance, strength and toughness are good. Hardness is not less than 89.5HRC, suitable as a variety of non-ferrous metal or wire, bar drawing dies.

4. YG6X: strength is more than 1800MPa, the hardness is not less than 91.5HRA, suitable for making drawing bore diameter of less than 6.00mm wire drawing dies.

5. YG8 (WC: 92%, Co: 8%):its toughness and shock resistance is higher than YG6 , but the wear resistance and hardness worser than YG6, hardness is not less than 89HRC, suitable as bar, tube drawing dies (50mm or less in diameter hit).

6. YG10: strength is more than 2400MPa, the hardness of not less than 88.5HRA, for the production of drawn steel and non-ferrous metal rod and tube drawing dies.

7. YG15: strength is more than 2800MPa, the hardness is not less than 87HRA, for the production of high shrinkage of drawn steel bars and tubes.

Tungsten carbide grade selection

In the standard tungsten carbide cold heading process, tungsten carbide cold heading die need to withstand greater shock, in order to meet the requirements, you must use the tungsten carbide with a higher amount of cobalt-containing, high strength and good toughness. Such as YG15, YG20, YG20C .

Core hole design of tungsten carbide wire drawing dies Die core hole tungsten carbide wire drawing dies generally contains five parts,which are the entrance area, lubricated area, work area,sizing zones and export zones.

1. The entrance area. To prevent scratches and improve the condition of steel to produce a lubricant into the work area will be designed carbide drawing dies Population Division into a circular shape.

2. Lubricate area. Lubrication district taper is generally 40, its length is roughly 50% equivalent to the work area.

3. Work area. Steel plastic deformation during the drawing process is done in the work area, in addition to performance, the size of the impact on the wire, also affects the power consumption , life and the the lubricant film thickness of tungsten carbide drawing die when drawing, and its main parameters are compression processing taper angle and length.

4. Sizing zones. The blank with the stability pass through the die, with a diameter sizing is to determine the finished size of the basic parameters. Bearing length is too long. will increase friction; too short, easy to wear carbide drawing die and cause bending of the material.

5. Export zones. Protection sizing section will not crack, and given frictional heat gauge portion has been sporadic, and avoid scratching the steel die after being pulled out.

Tungsten carbide wire drawing dies are very important expendable dies for drawning wire to all kinds of metal wire manufacturers (such as wire and cable, steel cord, wire rod plants, etc.)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Wood Pellets 6mm from Vietnam Acacia Wood Pellets Rubber

API 5CT Coupling

Marine Loading Arm

Semiconductor Wafers

Raw Wool

China

China