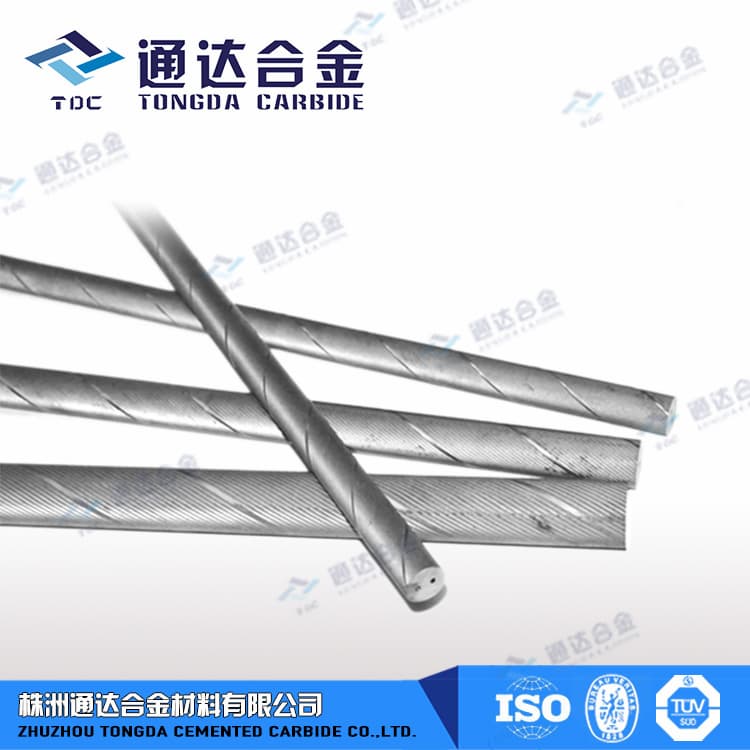

Tungsten Carbide Threaded Rod

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Threaded Rod | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | threaded rod , tungsten carbide threaded rod , carbide threaded rod | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

The comparison of thread milling and traditional tungsten carbide threaded rod processing method

The traditional method of threading mainly adopts screw thread cutting tools, or uses screw taps and manual screwing die to tap and set clasps. With the development of CNC machining technology, especially the three-axis NC machining systems has enabled more advanced ways of threading - Thread Milling can be achieved. Thread milling compared with the traditional way of threading, has a great advantage in the processing accuracy and processing efficiency, and the processing is not threaded to the thread structure and the restrictions, such as a thread mill can process a variety of different spin of the internal and external threads. As for the threads with transitional buckled or refund groove structure, using the traditional method of turning,screw tap or screw die is header to process than the use of CNC milling. In addition, the thread milling cutter is not only a dozen times or even tens of times more durable, but also in the process of CNC thread milling, the adjustment of thread diameter is very convenient. As the advantages of thread milling, currently the developed countries have extensively used the milling process on the large scale production.

The introduction of tungsten carbide threaded rod

Mold is the precision machinery, mold manufacturing costs high. Therefore, for the sake of the quality of the workpiece, a large mold thread is processed with thread milling in order to ensure accurate center distance of the hole and the fullness of the thread profiles.

Non-rotating type or non-symmetric parts As the parts sre asymmetrical, with the thread method of turning, the difficulty is clamping, but machining accuracy can be guaranteed.

Large bore diameter and intermittent cutting.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Heat Resistant alloy Rubber blade v plough belt cleaner

belt cleaner conveyor belt cleaner primary PU cleaner

Raw Wool

High Fin Tube

Electro Galvanized Wire

China

China