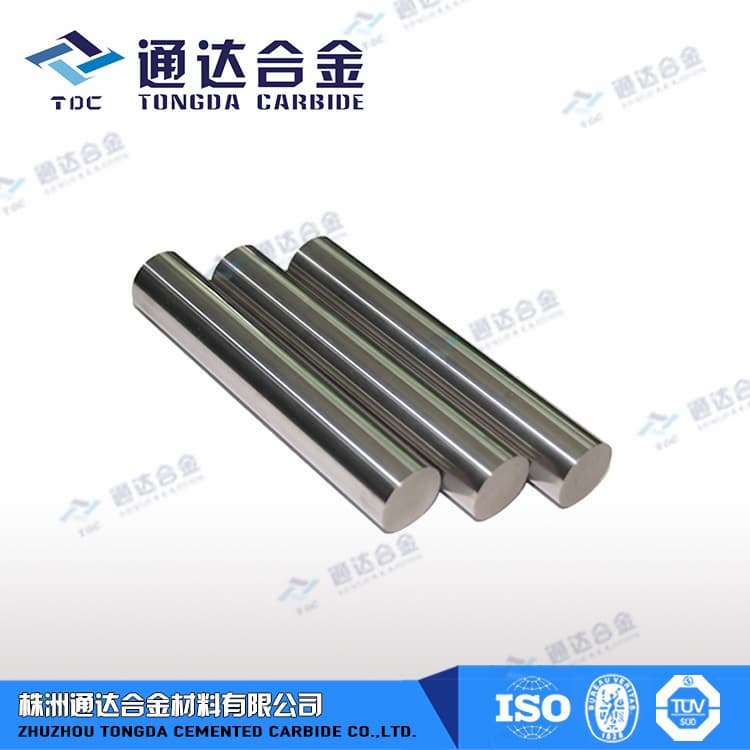

Solid Tungsten Carbide Rods

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Solid Tungsten Carbide Rods | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | carbide rods , tungsten carbide rods , solid tungsten carbide rods , solid carbide rods | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Applications of Solid Tungsten Carbide Rods

solid tungsten carbide rodsSolid tungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals. Various carbide grades with stable properties have been widely recognized by worldwide makers of tools. Besides, solid tungsten carbide rods are widely used processed as HSS Cutting tool, carbide end mills, carbide cutting tool, NAS cutting tool, carbide end mill, aerospace cutting tool, carbide drill, high speed steel, milling cutter Core drill, taperd end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, metal cutting saw, double margin drill, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter.

For PCB drills, micro drills, end mills and reamers, mould punches, core pins & hole drilling tools

Submicron grade features in high wear resistance, toughness & combination abilities

Good straightness, the roughness and surface roughness of finish ground rods are satisfactory.

Advanced production technology, automatic pressing, HIP sintering and precision grinding

Features of Solid Tungsten Carbide Rods

New technology, new material, stable in mechanical properties, easy soldering, high wear resistance and high impact resistan. For your reference,I am enclosing a very frequently used grade for your reference.

All our solid tungsten carbide rods are made from extrusion method and HIP Sintered, with excellent quality and performances.

Product Specification

1. Submicron grade features in high wear resistance, toughness & combination abilities

2. Good straightness, the roughness and surface roughness of finish ground rods are satisfactory.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Semiconductor Wafers

High Fin Tube

Metal Sticker for Credit Card

PUP JOINT 4 ½“12.6 PPF EUE 8RD 4FT LONG L80

VIET NHAT STEEL Corp

China

China