Leading exporter of submerged arc welding flux in China

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Yulin Welding Material

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Welding Fluxes

Gongyi Yulin Welding Material Co., Ltd

- Verified Certificate

-

8

| Product name | Leading exporter of submerged arc welding flux in China | Certification | - |

|---|---|---|---|

| Category | Welding Fluxes | Ingredients | - |

| Keyword | submerged arc welding flux , saw flux , sub arc flux , welding flux exporter | Unit Size | - |

| Brand name | Yulin Welding Material | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 381090 |

Product Information

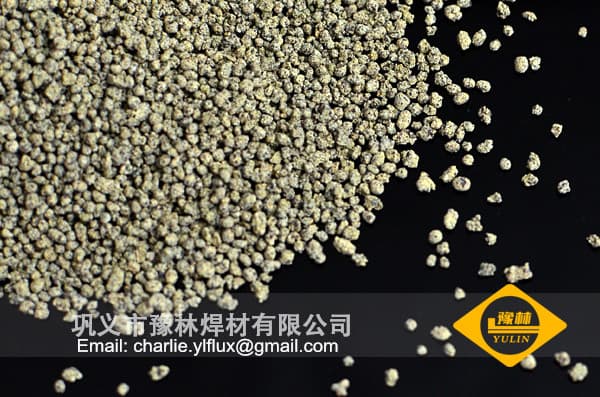

Name: Agglomerated submerged arc welding flux SJ101G

AWS: AWS/ASME SFA-5.17 F7A4-EH14

SAW wires: EM12, EM12K, EH14, etc.

Power supply: DC (DCEP), AC

Basicity: ≥1.8 BIIW

Graize size: 10-60 mesh (0.28-2.0mm)

Alloy transfer: nearly no transfer of Mn, Si to weld metal

Category: submerged arc welding mild steel & low-alloy steel

Industry: oil, gas pipeline construction, structural steel, pressure vessel, ship building, heavy machinery, spiral pipe mills, etc.

Description: submerged arc welding flux made by superior raw materials, can sufficiently meet the requirement of gas/oil pipeline welding (API grade 60, X65, X70). Fluoride based agglomerated welding flux. Easy slag removal. Excellent mechanical properties. High impact toughness. Even under high heat input conditions, weld metal has good impact toughness. Applicable for single wire, multiple wire welding.

Package: damp-proof packing, 25kg/bag

Certification: ABS, CCS, LR

Chemical Composition of Flux (%)

Mechanical Properties of Deposit Metal

Attention:

1. We get values in data sheets from tests carried out in accordance to AWS and GB standard procedure. They only represent values we get under those conditions. They are not to be taken as guarantees. As to welding, individual test results may vary depending on experience & technique, flux type, base metal, joint preparation,

flux preparation, ampere, voltage, etc.

2. If welding fluxes are stored in improper environment or influenced by condensed moisture, anyway, they get damp, please dry them at 300-350℃ for 2 hours before usage.

3. Please clean the rust, oil, water on base metal before welding.

4. Add minumum 20% new flux when using recovered flux to avoid welding defects and maintain welding performance & mechanical properties.

5. Please control parameters properly, like preheat temperature, interpass temperature, cooling rate.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Mr. Liu

- Address

- Wanghe Village, Dayugou Town, Gongyi City, Henan Province, China

- Product Category

- Welding Fluxes

- Year Established

- 1998

- No. of Total Employees

- 51-100

- Company introduction

-

Gongyi Yulin Welding Material Co. Ltd is engaged in the research & development & production of submerged arc welding fluxes (SAW flux). Our competitive products are agglomerated flux, fused flux, welding wires. Taking a leading position in regards to mild steel & low-alloy steel welding, heat resistant stainless steel welding, roll rebuilding & hardfacing, we are providing solutions for applications like pipeline, heavy machinery, pressure vessel, LPG tanks, vehicle, shipbuilding, bridge building, steel construction.

With state-of-the-art technology, our products are continuously aligned to the up-to-date specifications of the most demanding industries. Now we have develop a complete product portfolio to meet with different demands. Yulin production line is capable of 25,000 ton/year of agglomerated flux and 5,000ton/year of fused flux. Our capacity gives us the ability to provide welding flux for thousands of customers all over the world.

Welcome to contact and visit us, the biggest manufacturer and exporter for welding flux & wire in China is waiting for you.

- Main Markets

-

Bangladesh

Bangladesh

India

India

Indonesia

Indonesia

Malaysia

Malaysia

Pakistan

Pakistan

Philippines

Philippines

Singapore

Singapore

South Korea

South Korea

Taiwan

Taiwan

Thailand

Thailand

- Main Product

Related Products

Flux coreds ARC welding machine

Hj431 Welding Flux

Vacuum Brazing Pastes for PCD / PCBN Alloy Materials Vacuum Welding Flux

Welding Flux LH-SJ301

Welding Flux Powder HJ107, Fused Flux

China

China