SI2230 electronic components potting silicone sealant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Sepna

- Payment Terms

- D/A,D/P,L/C,Others,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Silicone Sealants

Shanghai Sepna Chemical Technology Co., Ltd.

- Verified Certificate

-

8

| Product name | SI2230 electronic components potting silicone sealant | Certification | - |

|---|---|---|---|

| Category | Silicone Sealants | Ingredients | - |

| Keyword | adhesive glue , silicone sealant , silicone adhesive , silicone adhesive glue | Unit Size | - |

| Brand name | Sepna | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Quick Details

| CAS No.: | Other Names: | MF: | |||

| EINECS No.: | Place of Origin: | Classification: | |||

| Main Raw Material: | Usage: | Brand Name: | |||

| Model Number: | Type: | Product name: | |||

| Application temperature: | Shelf life: | Packing: | |||

| Certificate: | ODM/OEM: | Shipping: | |||

| Samples:: | sample time: |

Packaging & Delivery

| Packaging Details: | Package for adhesive silicone sealant Part A--10 KG/Bucket, Part B--10 KG/ Bucket |

| Delivery Detail: | 10 days |

Technical Data Table of adhesive silicone sealant

PROPERTY | STANDARD/UNITS | VALUE of SI2230 | |

---- | ---- | PART A | PART B |

Color | Visual inspection | white / black viscous liquid | white viscous liquid |

Viscosity | 25°C, cps | 3500±500 | 3500±500 |

Density | 25°C, g/cm3 | 1.55±0.05 | 1.55±0.05 |

Mixture ratio | Mass ratio | A:B=100:100 | |

Viscosity of mixture | 25°C, cps | 3500±500 | |

Operation time | 25°C, min | 60±10 | |

Cure condition | RTV/HEAT | 25°C/ 4 hour; 80°C/ 30min | |

Cured appearance | ---- | White/ Gray-black elastomer | |

Hardness | Shore A | 55±5 | |

Thermal conductivity | W/mK | 0.80 | |

Linear expansion coefficient | K-1, ppm | 300 | |

Dielectric strength | kV/mm, 25°C | ≥20 | |

Volume resistance | DC500V, ohm-cm | 1.1×1015 | |

Loss factor | 1 MHz | 0.009 | |

Dielectric constant | 1 MHz | 3.00 | |

Application temperature | °C | -60~200

| |

Flame resistance | UL-94 | V-0 | |

Note:Above operation time and curing time was resulted based on 100g mixture, curing in 25°C, 55%RH for 7 days.

Key Feature of RTV adhesive silicone sealant

1. Two-part 1:1 mixture addition type silicone adhesive

2. Low hardening shrinkage

3. Excellent electrical insulation in high temperature and stability

4. Good waterproof and moisture resistance

5. Excellent flame resistance, UL No: E340199

Directions for Use

1. Mixing uniformity in the packing before using, as there’s part of filler sedimentation happens during storage.

2. Mix Part A and Part B by 1:1 mass ratio, after evenly mixed, pouring directly into the components or modules as per requirements. It’s recommended to slowly pour along the walls of the implements, so as to reduce the bubbles happens.

3. Still the potted component to let out the bubbles. Can be cured by heat, about 30 minutes in 80°C. If cured under room temperature, about 4 hours.

- Vacuum defoaming can improve the performance of cured product.

- Seal the remaining products tightly after use.

- Low temperature will slow the curing speed, overheating will lead to curing speed too fast. Keep the constant temperature in workshop is recommended.

- It's hard for SI2230 to cure if contact with sulfur, amine, organotin and unsaturated hydrocarbon plasticizer. Common substances like rosin, natural rubber. For these should do test before application.

Package & Storage

SI2230 color White/Black Part A--10 KG/Bucket, Part B--10 KG/ Bucket.

When stored at or below 35°C in the original unopened containers, this product has a usable life of 12 months from the date of production. Sampling test is necessary for products which exceed shelf life before taking use. During storage may have little settlement stratification, stirring evenly when use, does not affect performance.

It’s non-dangerous goods, can be transported as normal chemicals, CAUTION leakage during transport.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,Others,T/T | Shipping time | Negotiable |

- President

- Cena Ma

- Address

- No.1129 Denghui Road, Minhang District, Shanghai, China

- Product Category

- Adhesive & Sealants for Transportation,Epoxy Adhesives,Other Adhesives & Sealants,Silicone Sealants

- Year Established

- 2003

- No. of Total Employees

- 101-500

- Company introduction

-

Shanghai sepna Chemical Co.,Ltd is a professional industry adhesive supplier ,manufacturing polyurethane/silicon/epoxy sealant and adhesive,has established since 2003.

In 2005 sepna introduced PUNADE technology from Switzerland.

Via the ISO90001:2000 certification.

In 2013 sepna introduce Drawing Machine technology and has put it into producing formally now.Sepna has professional factory which area is 8,500 square meters,and has 138 staffs,including more than 20 technical and R&D staffs.

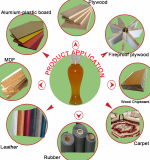

Application Field :

Electronics, Industry, Aviation, Automobile, Ship,Building,Rail vehicles, Power, Medical, LED, Semiconductor, New energy,etc.Production Concept:

Perfect performance;Utiliy;Natral;Advanced;Development;Economic;Distribution:

Sepna's products have been widely used in the international market, mainly in North America, South America, Asia, Southeast Asia Middle East and Oceania,etc.Until now,she has serviced nearly 1000 enterprises all over the world. And new product is being Researched and Developed more and more.

- Main Markets

-

Austria

Austria

France

France

India

India

Indonesia

Indonesia

Iran

Iran

North Korea

North Korea

Pakistan

Pakistan

Singapore

Singapore

Sudan

Sudan

Thailand

Thailand

- Main Product

Related Products

Structural Facade Sealant SG300

Sealants, Adhesives and Caulks

TIGER SEAL_Neutral

benzene free chloroprene resin adhesive for All Purpose

Silicone Sealants E3000 Acrylic Silicone Sealant

China

China